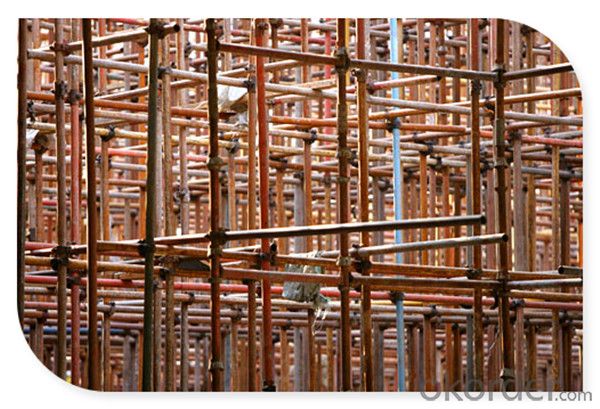

Construction Concrete Slab Formwork Steel Galvanized Cuplock Scaffolding System CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Construction Concrete Slab Formwork Steel Galvanized Cuplock Scaffolding System

Name Cuplock Scaffold System Size Many sizes or as your request Main Material Q235/345 Steel Surface Treatment High Protected Painted, Powder Coating, Electric Gavenized, Hot Dip Gavenized. Color Silver, Orange, Red Certificate SGS, EN12810. Service OEM Service available MOQ 50T Payment T/T, Western Union Delivery Time 15-25 days after deposite Packing in bulk or steel pallet or as your request production capability 50 tons per day Main Market Africa, South America, the Middle East and Asia

Descriptions of Construction Concrete Slab Formwork Steel Galvanized Cuplock Scaffolding System

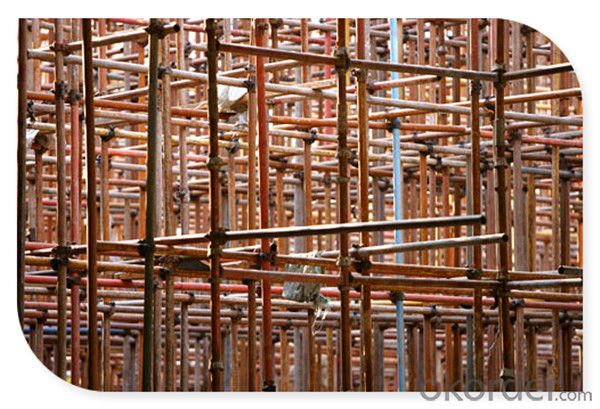

Cuplock is a kind of multi-purpose and versatile modular system scaffolding, suitable for access and formwork support in all types of construction of building & civil engineering projects, offshore projects, etc. This complete galvanized Cuplock system is probably the fastest and most widely preferred scaffolding system. It has flexible erection as straight, curved or circular configuration for both access and support purposes.

Futures of Steel Cuplock Scaffolding System for Concrete Building Construction

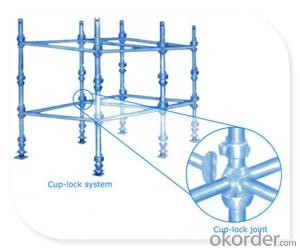

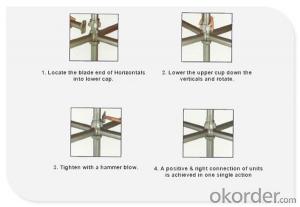

1.Cuplock scaffold system is simple in structure,including top cup,bottom cup and ledger blade.

2.Quick installation of horizontals and verticals,you can easily fit the ledger blade into the cups with a hammer.

3.Cuplock scaffold system standards are made from higher quality steel tube which allow more than 58KN load per leg.

4.Cuplock scaffold system is a multi-functional scaffolding system which is suitable for all forms of access and support structures,especially used in bridege building.

5.People can fasten joint of ledgers by putting two extra ledger blades in the cups.

6.This cuplock scaffold system are interlocked by cups and ledgers which is very safe and stable steel scaffolding system.

7.This is a heavy duty scaffold system which can load about 16tons for each cuplock scaffolding system.

8.Cuplock scaffold system can be used both interior or outerior high-rise building construction project, expecially for arc shape building such as bridge, tunnel, subway, or gym building. it's multifunctional.

9.This is a galvanized cuplock scaffold system which surface is hot dip galvanized, it can keep a longer working life.

10.Gavanized cuplock scaffold system is water-proof scaffold sysem which can prevent the air and water to damage the cups and ledgers very effectively.

11.Cuplock scaffold system can be quick to errect by interting the cuplock blade into bottom cup, then swivel the top cup to fixed it.

12.Suitable for transportation and storage: Single cuplock scaffold system standard and ledger occupy less space. Wiht no extra parts.

The Measures of Construction Concrete Slab Formwork Steel Galvanized Cuplock Scaffolding System

Standard: 3000mm, 2500mm, 2000mm, 1500mm, 1000mm, 500mm.

Ledger: 3000mm, 2000mm, 1780mm, 1500mm, 1000mm, 500mm.

Diagonal brace: 3000X2000mm, 1780X2000mm, 1000X1500mm, 1000X2000mm, 1500X2000mm,

Tube specification: Φ 48.3X4.0mm, φ 48.0 X3.25mm, φ 48.0 X3.0mmFAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q: Scaffolding installation and precautions?

- The backing plate and the base should be placed on the positioning line accurately.2, when the erection of the column, the outer diameter of the steel pipe is strictly prohibited, the adjacent column of the docking fasteners shall not be in the same height, staggered distance should meet the structural requirements.

- Q: i just got it like 3 days ago and its no signs of infection and im just worried it might get that way. ive been reading online about people who got infections and people who had all this crap happen. what do i need to do to stop one from coming i mean i use contact solution and cotton swabs wipe it down with wet ones and clean it when i sweat and turn it twice a day.. im always careful about keeping it clean im a neat clean freak but is there anything else i can do to stop infection from coming

- go to safepiercing.org for proper aftercare and what to avoid. if you use store bought saline, make sure it is additive free, but, the sea salt soaks on the above site works much better. also, stop turning it. it disrupts the newly forming skin which prolongs healing and makes you more prone to infection. turning the earring is something that comes from the old way of ear piercing (with a gun). it does not apply to any other piercings, and, we know now that it's not good for any piercing. the 'gun piercers' aren't real piercers and don't know anything about it also, it takes up to a year to heal

- Q: What is the mobile scaffolding materials

- About looking for specific mobile scaffolding, I suggest you here to see the mobile scaffolding, mobile scaffolding here all, other parts of the mobile scaffolding, mobile scaffolding may not fully determine where is here, you can find the mobile scaffolding, mobile scaffolding because it is easy to find, but now is not the mobile scaffolding too hard to find. About looking for specific mobile scaffolding, I suggest you here to see the mobile scaffolding, mobile scaffolding here all, other parts of the mobile scaffolding, mobile scaffolding may not fully here,

- Q: Im hoping to get an industrial/scaffold piercing done at the very beginning of the summer holidays.Is it possible that they can be pierced with 2 separate pieces of jewellery rather than one bar.Also would it be healed in time to take it out once the holidays are over (6 weeks)??Please help??!?Thanks x

- nope! Cartilage piercings take about a year to fully heal up. Yes, you can get 2 separate bars, but let the piercer know thats what you want. Industrials are VERY hard to take care of. Make sure to listen to EVERYTHING the piercer says!

- Q: I'm trying to understand a problem in my physics book. The problem is this:A person is pulling on a rope, that is connected to a pulley on the ceiling. The rope then goes to a box with a pulley on it, and then up to the ceiling where the rope is connected (to the ceiling).The rope and pulleys are massless and frictionless.The book lists three forces (tension forces) going up and one weight force pulling down.My question is, why isn't there another force pulling against the tension of the rope from the guy pulling the rope?

- The force felt by the person pulling is the same as the force in the rope between the two pulleys. It doesn't matter if the person is pulling straight up (without the pulley) or straight down(with the pulley) it's the same. Therefore the weight/force is divided equally between the two ropes.

- Q: Can you do the outer scaffolding?

- The safety net is fixed on the side of the outer vertical rod of the scaffold. (2) the 16# wire safety net, strict and smooth. (3) the outer side of the scaffold shall be provided with a 1.2m high protective railing and a 30cm high skirting bar, and the top row protective railing shall be not less than 2, with a height of 0.6m and 1.2m.

- Q: I'm reading the novel by nathaniel hawthorne. There seems to be a lot going on in the scaffold scenes that i kind of not understand. Can someone explain the significance of these scenes? I am not a fan of cliffnotes or sparknotes because i actually READ the books. please someone who has read it tell me, i appreciate it.

- do you mean the part where she's on the scaffold with pearl when she's just born or when the three of them hold hands and then the priest has to leave? Well either way, the scaffold means embarrassment, it's like having to wear the A but being more upfront with people so you don't really have to explain yourself, everyone just knows. That's the reason, i forget his name, the priest that's pearl's father, goes up to the scaffold, because no one knows he secretly wears the A that's why going on the scaffold allows him to free himself of guilt, he wanted everyone to know so he would stop living in hidden pain but when pearl and her mother come, it makes it too real for him, he kind of wakes up, you could say, so he becomes too frightened and decides not to carry out his plan.

- Q: ...and I'm not really sure what to expect. I know that everyones healing time and pain tolerence is different but just some personal storys would be nice. And before you say it I am aware that there are risks as there are risks with any piercing. so I'm 17 from London and wondering:How old do you have to be to get it done?Does anyone know a reputable place i can get it done?How much will it be?any experiences to share?

- Hi I got it done a few months ago I love it! Its really not that sore at all just a slight nip and then bit warm afterwards lol! Only thing annoyed me was couldn't sleep on it for a while and that was always the side I slept on! I live in Belfast and you can get it done from about 16. I just went to a well known tattoo parlour and had no problems what so ever. Go for it looks great Good luck :D

- Q: Right! I've heard from so many different people about this. Some say that you should never twist an industrial because it can damage the delicate newly healing skin cells. Others say that you must twist it to prevent the jewelry from healing attached to the skin and to be able to clean it properly.There really doesn't seem to be a definitive answer!My piercer has said not to twist it, so I haven't been, and I'm happy that the piercing is clean enough, etc. However I'm interested in whether any of you out there have found that not twisting it can damage it more than doing so.Thanks

- i twisted mine alot and the cartlidge inbetween has ripped and it hurts unbelievably loads, so i wouldnt twist it

- Q: This is an answer to irreducible complexity. Are there any examples that we see in animals or organs? or on the cellular level? Are vestigial organs a form of quot;scaffoldingquot; that are in the process of being removed?

- The classic demonstration was in the E. coli long term experiment. A strain gained the ability to metabolize citric acid after 31,500 generations. Culturing preserved strains from 15,000 and 20,000 generations showed that there was an event that occurred in between that enabled the later conversion to citrate metabolism.

Send your message to us

Construction Concrete Slab Formwork Steel Galvanized Cuplock Scaffolding System CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords