Galvanized Cuplock System Scaffolding|Scaffolding Cuplock System CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Galvanized Cuplock System Scaffolding|Scaffolding Cuplock System

Type: Heavy Section Steel

Forming: Welding Products

Standard:

Member:

Trademark:

Connection Form:

Carbon Structural Steel:

Residential Wall Structure:

Type of Steel For Building Structure:

Bs1139, En74 Standard:

Export Markets:

Descriptions of Galvanized Cuplock System Scaffolding|Scaffolding Cuplock System

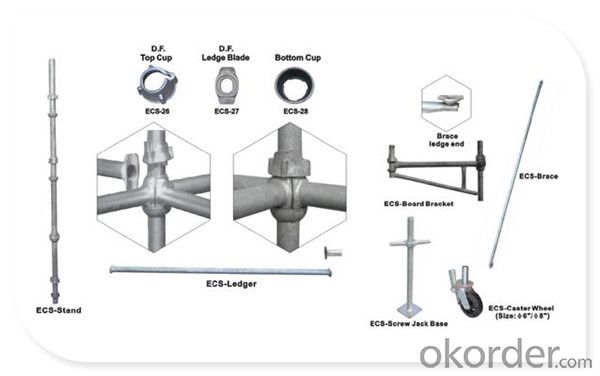

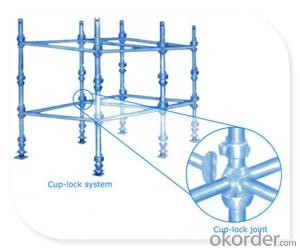

Cuplock is a kind of multi-purpose and versatile modular system scaffolding, suitable for access and formwork support in all types of construction of building & civil engineering projects, offshore projects, etc. This complete galvanized Cuplock system is probably the fastest and most widely preferred scaffolding system. It has flexible erection as straight, curved or circular configuration for both access and support purposes.

Futures of Galvanized Cuplock System Scaffolding|Scaffolding Cuplock System

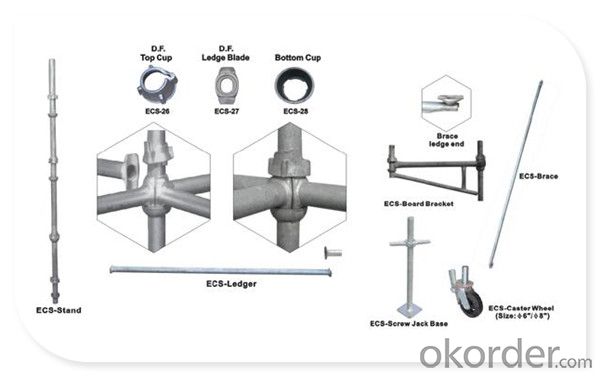

Multi-functional-with the universal joint and fully interchangeable components, the cuplock system can be used in most construction projects for both formwork and access. It is very versatile and diverse. Use in the shipping industries, oil and gas and aviation industries.

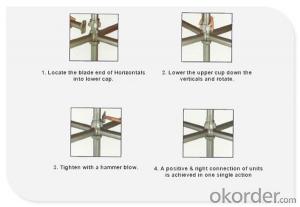

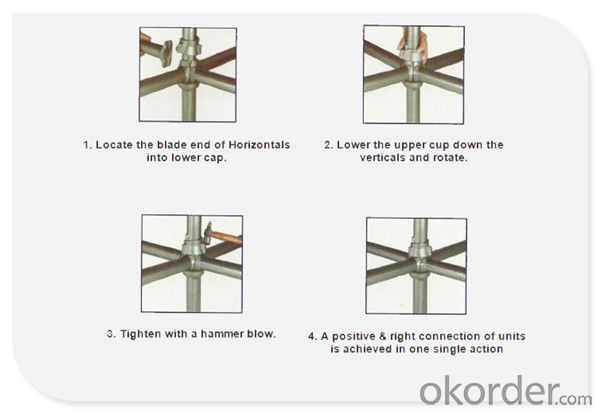

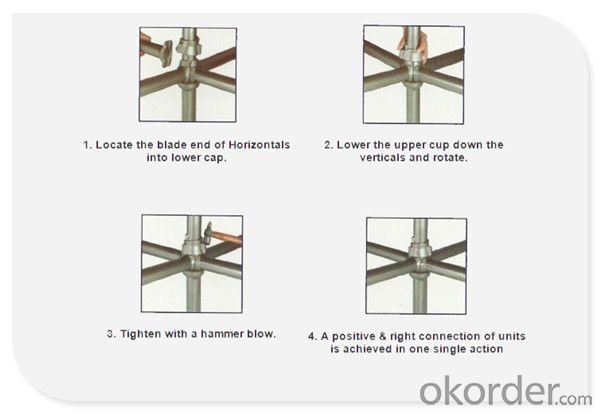

Versatile-Verticals are assembled with horizontals and diagonals using secure fixed cup connections. Its versatility has a distinct advantage to conventional scaffolding methods. A positive & ridged connection of four units is achieved in one single action. The cupock system is very cost effective and can be erected safely and quickly.

Time saving-cuplock scaffold is the solution for temporary structures Performance stages. Small teams can erect it safely and quickly.

Economical-Easily assembled system scaffold saves time and labor costs.

Durable-All components are hot dip galvanized and manufactures to international standard.

Easily Stored-Individual pipe elements can be packed in bundles for easy storage and transportation. For returns, material can be packed in steel racks.

The Main Components of Galvanized Cuplock System Scaffolding|Scaffolding Cuplock System

Verticals

Description

Material

kg/pc

Article No.

9'10" Vertical 3.00m

Q345 φ48.3×3.2

16.90

SC1001 3000

8'2" Vertical 2.50m

Q345 φ48.3×3.2

14.20

SC1001 2500

6'6" Vertical 2.00m

Q345 φ48.3×3.2

11.60

SC1001 2000

4'11" Vertical 1.50m

Q345 φ48.3×3.2

8.90

SC1001 1500

3'3" Vertical 1.00m

Q345 φ48.3×3.2

6.20

SC1001 1000

1' Vertical 0.50m

Q345 φ48.3×3.2

3.50

SC1001 0500

Horizontals

Description

Material

kg/pc

Article No.

10'0" Horizontal 3.05m

Q345 φ48.3×3.2

11.80

SC1002 3048

9'0" Horizontal 2.74m

Q345 φ48.3×3.2

10.70

SC1002 2743

8'2" Horizontal 2.50m

Q345 φ48.3×3.2

9.80

SC1002 2500

7'0" Horizontal 2.13m

Q345 φ48.3×3.2

8.40

SC1002 2133

6'6" Horizontal 2.00m

Q345 φ48.3×3.2

7.90

SC1002 2000

6'0" Horizontal 1.83m

Q345 φ48.3×3.2

7.20

SC1002 1828

5'11" Horizontal 1.80m

Q345 φ48.3×3.2

7.10

SC1002 1800

5'0" Horizontal 1.52m

Q345 φ48.3×3.2

6.10

SC1002 1524

4'11" Horizontal 1.50m

Q345 φ48.3×3.2

6.00

SC1002 1500

4'1" Horizontal 1.25m

Q345 φ48.3×3.2

5.00

SC1002 1250

4'0" Horizontal 1.22m

Q345 φ48.3×3.2

4.90

SC1002 1219

3'6" Horizontal 1.07m

Q345 φ48.3×3.2

4.30

SC1002 1067

3'3" Horizontal 1.00m

Q345 φ48.3×3.2

4.10

SC1002 1000

3'0" Horizontal 0.91m

Q345 φ48.3×3.2

3.80

SC1002 0914

2'11" Horizontal 0.90m

Q345 φ48.3×3.2

3.70

SC1002 0900

8'0" Horizontal 2.44m

Q345 φ48.3×3.2

9.50

SC1002 2438

1'10" Horizontal 0.57m

Q345 φ48.3×3.2

2.40

SC1002 0600

FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q: The bottom of the cantilever scaffold must be provided with the sweeping rod

- Product quality certificate and inspection report. Rust must be replaced, not to be used to build the frame.

- Q: Do the external wall decoration (from the top down to do) scaffolding is to wait until after the completion of the indoor and outdoor decoration before the demolition?If the first interior decoration, can make a layer of a layer of it is to remove all the work finished I mean I finished all the interior decoration, wall decoration only, then I do a wall decoration on the demolition of a layer of scaffolding, this site useful no

- Two, removal of scaffolding, should meet the following requirements:1, the demolition work must be from top to bottom layer by layer, prohibited from top to bottom operation at the same time;2, even the wall must be removed with the scaffolding layer by layer, is strictly prohibited even after the first wall or a few layers of the demolition of the demolition of the scaffolding; demolition of the height difference should not be greater than 2 steps, such as the height difference is greater than the step, should be added to strengthen the wall;3, when the scaffolding down to the bottom of a long rod height (about 6.5m), should be in the appropriate position to set up temporary support reinforcement, and then dismantle the wall;4, when the scaffolding to take the sub section, the demolition of the sub elevation, the demolition of the scaffold should not be removed at both ends, should be added to the wall and lateral oblique reinforcement.

- Q: Write a scaffold method for 743,425 divided by 365EASY 10 points

- use a calculator you punk, nobody writes out division anymore, grab your ti-84 and type it out... there's your scaffold method jerk.

- Q: I couldn't believe it, but yes it happened...

- Yes I can. Did you hear about that drunk guy who survived a 17 story hotel fall. I think he ended up having a broken foot.

- Q: What's the film where gene Kelly dances on scaffolding? And at a gym?

- I think it's Living in a Big Way.... I could be wrong...

- Q: What does my earth science teacher mean when he says to do a powerpoint with Link Scaffolding,how d u do it?

- Link Scaffolding = A search found no answer. - Ask teacher to clarify.

- Q: Is it easier to build a disc scaffolding system than a bowl buckle scaffold?

- It is widely used in bridge engineering, tunnel engineering, workshop, elevated water tower, power plant, oil refinery... Support design and special plant, is also applicable to overpass span scaffolding, storage shelves, chimney, water tower and indoor and outdoor decoration, large concert stage, the background frame, stands, balcony frame, stairs, other party system, stage setting, sports watch station project.

- Q: What are scaffold spanners used for?

- Ratchet Podger Spanners...Aluminium Scaff Spanners Spanners are wide wrenches that are made from durable metals. Spanners are made specifically for scaffolding and are designed to fit into the tool belt nicely. Spanners are very useful for a number of jobs and are often used along with other scaffold tools on a safety lanyard to prevent dropping the tool to the street below. Spanners work the same as traditional wrenches but like many scaffolding tools are made with a hole in the end of the wrench for the safety strap to be inserted through. Stainless steel and aluminum are the most commonly used metals for spanners to ensure durability even if the item is dropped from high.

- Q: hi, i already have my cartlidge pierced on my right ear and thinking about getting a scaffold piercing on my left ear. will a scaffold piercing hurt more than my cartlidge piercing,,less,,or about the same???thanks answers apprecietedhope =] xx

- Several people have told me it hurts about the same. I do not have one, sorry couldn't be more help than that.

- Q: I got my scaffolding approximately about 7 weeks ago maybe just a lil over, I want to know when is a good time to change the bar/take it out, I am keeping up with cleaning it 2 to 3 times a day with the saline solution, even though, it only requires to be cleaned 1-2 times a day to be fair though

- 9-12 months of healing time so 9-12 months until you change it. You should never change an unhealed piercing. Take it from someone who had to retire her industrial piercing from changing it too early, leave it alone until it is 100% healed.

Send your message to us

Galvanized Cuplock System Scaffolding|Scaffolding Cuplock System CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords