Q235 Galvanized Steel Cuplock Scaffolding System for Large Building Construction CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Q235 Galvanized Steel Cuplock Scaffolding System for Large Building Construction

Type: Heavy Section Steel

Forming: Welding Products

Standard:

Member:

Trademark:

Connection Form:

Carbon Structural Steel:

Residential Wall Structure:

Type of Steel For Building Structure:

Bs1139, En74 Standard:

Export Markets:

Descriptions of Q235 Galvanized Steel Cuplock Scaffolding System for Large Building Construction

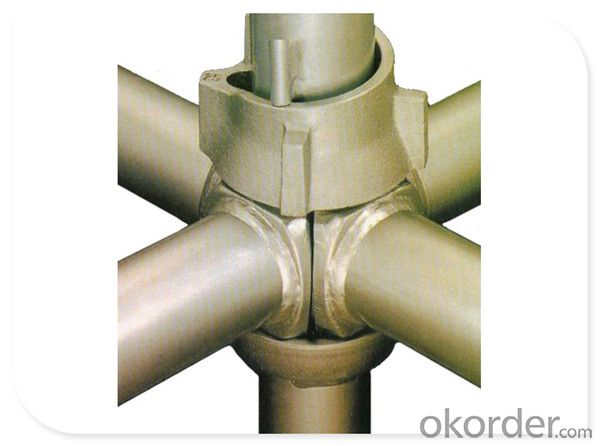

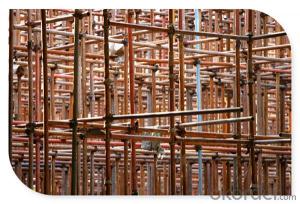

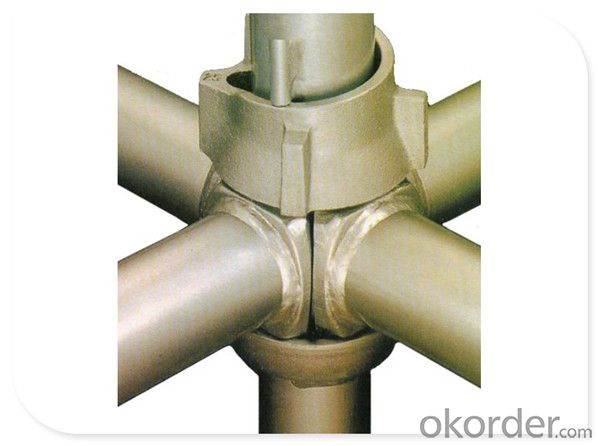

Cuplock is a kind of multi-purpose and versatile modular system scaffolding, suitable for access and formwork support in all types of construction of building & civil engineering projects, offshore projects, etc. This complete galvanized Cuplock system is probably the fastest and most widely preferred scaffolding system. It has flexible erection as straight, curved or circular configuration for both access and support purposes.

Futures of Q235 Galvanized Steel Cuplock Scaffolding System for Large Building Construction

Multi-functional-with the universal joint and fully interchangeable components, the cuplock system can be used in most construction projects for both formwork and access. It is very versatile and diverse. Use in the shipping industries, oil and gas and aviation industries.

Versatile-Verticals are assembled with horizontals and diagonals using secure fixed cup connections. Its versatility has a distinct advantage to conventional scaffolding methods. A positive & ridged connection of four units is achieved in one single action. The cupock system is very cost effective and can be erected safely and quickly.

Time saving-cuplock scaffold is the solution for temporary structures Performance stages. Small teams can erect it safely and quickly.

Economical-Easily assembled system scaffold saves time and labor costs.

Durable-All components are hot dip galvanized and manufactures to international standard.

Easily Stored-Individual pipe elements can be packed in bundles for easy storage and transportation. For returns, material can be packed in steel racks.

The Main Components of Q235 Galvanized Steel Cuplock Scaffolding System for Large Building Construction

Verticals

Description

Material

kg/pc

Article No.

9'10" Vertical 3.00m

Q345 φ48.3×3.2

16.90

SC1001 3000

8'2" Vertical 2.50m

Q345 φ48.3×3.2

14.20

SC1001 2500

6'6" Vertical 2.00m

Q345 φ48.3×3.2

11.60

SC1001 2000

4'11" Vertical 1.50m

Q345 φ48.3×3.2

8.90

SC1001 1500

3'3" Vertical 1.00m

Q345 φ48.3×3.2

6.20

SC1001 1000

1' Vertical 0.50m

Q345 φ48.3×3.2

3.50

SC1001 0500

Horizontals

Description

Material

kg/pc

Article No.

10'0" Horizontal 3.05m

Q345 φ48.3×3.2

11.80

SC1002 3048

9'0" Horizontal 2.74m

Q345 φ48.3×3.2

10.70

SC1002 2743

8'2" Horizontal 2.50m

Q345 φ48.3×3.2

9.80

SC1002 2500

7'0" Horizontal 2.13m

Q345 φ48.3×3.2

8.40

SC1002 2133

6'6" Horizontal 2.00m

Q345 φ48.3×3.2

7.90

SC1002 2000

6'0" Horizontal 1.83m

Q345 φ48.3×3.2

7.20

SC1002 1828

5'11" Horizontal 1.80m

Q345 φ48.3×3.2

7.10

SC1002 1800

5'0" Horizontal 1.52m

Q345 φ48.3×3.2

6.10

SC1002 1524

4'11" Horizontal 1.50m

Q345 φ48.3×3.2

6.00

SC1002 1500

4'1" Horizontal 1.25m

Q345 φ48.3×3.2

5.00

SC1002 1250

4'0" Horizontal 1.22m

Q345 φ48.3×3.2

4.90

SC1002 1219

3'6" Horizontal 1.07m

Q345 φ48.3×3.2

4.30

SC1002 1067

3'3" Horizontal 1.00m

Q345 φ48.3×3.2

4.10

SC1002 1000

3'0" Horizontal 0.91m

Q345 φ48.3×3.2

3.80

SC1002 0914

2'11" Horizontal 0.90m

Q345 φ48.3×3.2

3.70

SC1002 0900

8'0" Horizontal 2.44m

Q345 φ48.3×3.2

9.50

SC1002 2438

1'10" Horizontal 0.57m

Q345 φ48.3×3.2

2.40

SC1002 0600

FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q: i already found the force in rope 2 but im not getting the force in rope 1.

- difficult situation. search in google or bing. that could actually help!

- Q: Sweeping rod, large cross bar, small cross bar, scissors brace, vertical pole, right angle fastener, rotating fastener, butt joint fastener, even wall piece! If there is a cantilever frame, the main beam, steel wire rope, such as pull down support

- Mobile scaffolding is the main frame, cross frame, cross diagonal brace, foot board, adjustable base and other components. The cross rod is also called the diagonal pull rod, and is a cross connecting rod which is vertically connected with the two door frames. The part of both ends of the rod part is punched with a pin hole, and the locking pin on the vertical rod of the door and the frame is locked when assembling.

- Q: Im in college football, I would be puting on and taking off my helmet, I usually keep it on though during practice...but would it be wise for me to get an industrial piercing a couple months before 2 a days and the football season...would the sweat maybe infect my ear, but I am a very clean guy? thanks, if you have an answer it will help my decision.....

- id leave it. theyre hard to heal nyway,and the added pressure of the helmet and the sweat and the possibility of getting hit in the head and knocking the piercing....well, i wouldnt risk it

- Q: What are the main safety problems when dismantling the scaffold

- 3, the demolition of spare parts to be loaded into the container, with a crane hanging; the steel pipe to be tied to secure, double point lifting, prohibited from high altitude thrown.4, more than six wind (including level six) to stop the construction of mobile scaffolding.

- Q: I'm a civil engineering student and we were asked to submit a paper about designing a simple scaffolding. I just want to see a sample paper so that I would know what details should I include.

- can't draw here, but it's just an x with a flat board on top in 3 dimensions.

- Q: Cantilever beam type scaffolding can not exceed the maximum number of not married

- Cantilever scaffold cantilever beam fixed method is as follows:1, the floor in the rebar at the same time, the embedded two door shaped clamp, each clamping hoop is composed of 2 14mm grade steel made a root diameter, the first door shaped clamp from the wall 450mm, second door shaped clamp from the other end of the 350mm, the door shaped card hook stirrup slab reinforcement, to meet the requirements of the anchorage the cantilever beam, door shaped clamp is inserted in the middle, but also with a fixed electric welding.

- Q: Can anybody provide me the formula for calculating scaffold volume on circular tank?

- Step 1. Measure the diameter of the tank (D). Step 2. Measure the height (h) for a vertical tank or length (l) of a horizontal tank. Step 3. Calculate the cross-sectional area of the tank using Equation 1. Equation 1: Cross-sectional Area, A = 3.14 x D x D/4 Step 4. Calculate the volume of the tank in cubic feet using Equation 2. Equation 2: Volume in cubic feet = A x h [for a vertical tank] Volume in cubic feet = A x l [for a horizontal tank] Step 5. Convert the volume of the tank from cubic feet to gallons using Equation 3. Equation 3: Volume in gallons = (Volume in cubic feet) x 7.48

- Q: Was thinking of getting one. How much do they cost?

- Only a professional piercer can decide if your ear can handle and industrial piercing. Consultations are free and I highly recommend booking one before you get the piercing. Mine was $70, but my regular piercer does them for $50. It just depends on what shop you go to.

- Q: Specification and type of scaffold erection

- Specification for scaffold erection(a) basic requirements1 important scaffolding must develop a construction plan, if necessary, to develop safety assurance measures. 2 more than 25m high scaffolding must adopt the fastener type steel tube scaffold, the single pole scaffolding height should be controlled within 50m; height of more than 50m of the scaffolding should be effective measures by a double pole, wire rope, cable stayed unloading segment, and additional design.3 the design of the scaffold shall meet the requirements of the project and shall indicate its use, maximum static load, maximum dynamic load andThe selected design parameters and structural parts shall not be lower than the existing national and industry related safety technical standards.4 scaffolding in the construction of the need to change the original structure, Gago (wide), to its use, etc., must be verified by the technical department, and the approval.

- Q: male scaffolders only if i was swinging on the scaffold would ya stomp on my fingers with ya workboots on?

- depends how many times have i told you to get off?

Send your message to us

Q235 Galvanized Steel Cuplock Scaffolding System for Large Building Construction CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords