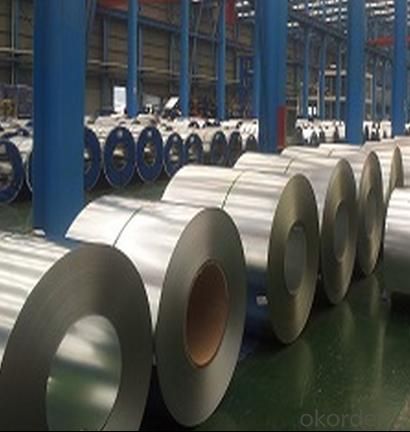

Galvanized Steel Coils/Rolled Steel Coil Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Info.

Model NO.:CGCC, JIS3312

Surface Treatment:Coated

Certification:ISO, SGS

Technique:Cold Rolled

Standard:ASTM, JIS, GB

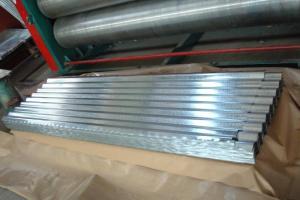

Application:Construction, Roofing and So on

Edge:Slit edge

Stock:Stock

Steel Grade:Q195-235

Thickness:0.16-0.8mm

Width:800-1250mm

Color:Ral Number

Zinc:30G/M2-100G/M2

Coils Weight:3-5tons/Coils

Export Markets:Global

Additional Info.

Packing:Export Standard Packing

Standard:JIS G3312

Origin:China

HS Code:72107000

Production Capacity:100000tons/Year

Product Description

Prepainted galvanized steel coils

1. PPGI, prepainted galvanized steel coil(Annual Output: 200, 000tons)

(1). Leading manufacturer in China

(2). Competitive price

(3). High quality

(4). Good after-sale service

2. The Feature of PPGI:

1). Geade: CGCC, other grade can be available

2). The thickness range of the PPGI: 0.16mm to 0.8mm

Tolerance of thickness of The PPGI: +/-0.03mm

3). Width range: 800mm to 1250mm

Tolerance of width: +/-3.00mm (aiming to +/-2.00mm)

4). Zinc coating: Z40-Z275

5). Coil internal diameter: 508mm

6). Packing: Standard waterproof paper and galvanized steel protection cover and steel strip packed

7). Applications of PPGI: Widely used for roofs, outer walls, ovens, Explosive-proof steel, electrically controlled cabinets, and industrial freezers in the Residential and industrial buildings

- Q: I'm building a single-speed commuter bike and I was wondering what the advantages and disadvantages of steel and alloy wheels are. Any experts out there who can give me specifics for each kind?

- Steel wheels are at the lowest cost and quality end of bike equipment. If you're even thinking of buying a cheapo bike with steel wheels - don't. Steel wheels are poor quality and therefore weaker than an OK alum rim. They are heavier, braking isn't as good, won't stay true as long. Alum wheels are extruded, not cast, and are better in every way. They cost more is the only down side.

- Q: How are steel coils used in the manufacturing of exhaust systems?

- Steel coils are used in the manufacturing of exhaust systems as they provide the necessary raw material for forming various components such as pipes, mufflers, and brackets. The coils are typically processed through cutting, bending, welding, and shaping techniques to create the specific parts required for the exhaust system.

- Q: How are steel coils processed and shaped for specific applications?

- Steel coils are processed and shaped for specific applications through a systematic manufacturing process. Initially, the coils are uncoiled and flattened, followed by cleaning and coating to protect against corrosion. Then, they undergo a series of shaping processes such as rolling, bending, or cutting, depending on the desired application. These processes help transform the steel coils into various forms, including sheets, plates, or strips, which can be further fabricated into specific products like automobiles, appliances, or construction materials.

- Q: a picture of the atomic structure of carbon steel

- This is actually a quite complex question... The atomic arrangement in steels can be controlled over a pretty wide range of different structures. This is really the fundamental reason why steel is such a commonly used material. The different atomic structures produce different physical properties so metallurgists have developed many different processes to control the atomic structure to get the properties they want. One simple answer is that Fe is BCC, body centered cubic at room temperature at equilibrium conditions. When you heat Fe up, it transforms to FCC, face centered cubic. If you continue heating Fe, it goes back to BCC, then it melts. The addition of C makes these structures (and the transformation temperatures) different. Deviating from equilibrium conditions by, for example, cooling very quickly (quenching) creates different atomic structures (one of the most important is known as martensite). Depending on how much C is in the steel, you can also have two different atomic structures (two different phases) present in equilibirum, for example, pearlite which is a mix of alpha Fe (BCC) and iron carbide Fe3C (orthorombic crystal structure). So... you need to think a little more about exactly what you want a picture of. I hope this helps

- Q: i have a computer chair where the metal part that attachs the top part to the bottom with wheels has cracked around half of the assembly. my dad said it might be able to be repaired with jb weld. can jb weld fix it? how strong is jb weld? is it as strong as steel?

- There is going to be too much stress at that mounting point for jb to work for long, unless you plan on never leaning more than 5 degrees from prostrate. Buy a new or used one. They are cheap if your not too picky. If you do plan on using jb, i highly recommend drilling multiple 1/8 or so holes on both sides of the crack, and smash some jb into those holes as you patch it. That will allow the jb to hold on much better.

- Q: What are the common coil processing methods?

- Some common coil processing methods include slitting, shearing, blanking, leveling, and edging.

- Q: I'm assuming that brass is flexible, expands and then bounces back to it's original shape. But if aluminum and steel expand and don't contract wouldn't they cause guns to jam more often for example?

- This Site Might Help You. RE: Why can aluminum and steel casings not be used for reloading? I'm assuming that brass is flexible, expands and then bounces back to it's original shape. But if aluminum and steel expand and don't contract wouldn't they cause guns to jam more often for example?

- Q: What are the common welding methods used for steel coils?

- The common welding methods used for steel coils include shielded metal arc welding (SMAW), gas metal arc welding (GMAW), flux-cored arc welding (FCAW), and submerged arc welding (SAW).

- Q: i am working a client.my vendor specified in pipe specification pipe line class as MS1 (code for Mild steel)but assigned material to this code is cs smls astm A 106B.my question is any difference between CS and MS material?pls suggest me

- *Carbon steel, also called plain carbon steel or Mild Steel, is steel where the main alloying constituent is carbon. The AISI defines carbon steel as: Steel is considered to be carbon steel when no minimum content is specified or required for chromium, cobalt, columbium, molybdenum, nickel, titanium, tungsten, vanadium or zirconium, or any other element to be added to obtain a desired alloying effect; when the specified minimum for copper does not exceed 0.40 percent; or when the maximum content specified for any of the following elements does not exceed the percentages noted: manganese 1.65, silicon 0.60, copper 0.60. If it crosses limit as said, it will come under alloy steel. ASTM A 106 gr B is a carbon steel pipe and seamless Pipe for High Temperature Service. So, it will be a mild steel comes under carbon steel category.

- Q: I am about to do a welding project and we are instructed to only use mild steel. I want to use found objects like coins, spoons, bottle caps, screws, and other small fasteners. Are these mild steel? What other objects can I use that are mild steel?

- Mild steel is what your friends get when they see your mom's cleavage.

Send your message to us

Galvanized Steel Coils/Rolled Steel Coil Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords