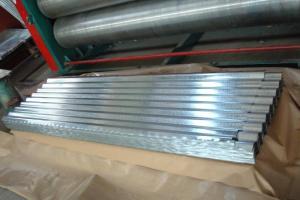

GALVANIZED CORRUGATED STEEL

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

product information:

1)Operate Standard: ASTM A653M-04/JIS G3302/DIN EN10143/GBT 2518-2008

2)Grade : SGCD,SGCH, Q195,DX51D

3)Galvanized steel sheet /coil features:

4)Zinc coating :40-180g( as required)

5)width:914-1250mm(914mm, 1215mm,1250mm,1000mm the most common)

6)coil id:508mm/610mm

7)coil weight: 4-10 MT(as required)

8)surface: regular/mini/zero spangle, chromated, skin pass, dry etc.

9)application: Structural use ,roofing, commercial use, household appliance, industry, family;

special application: Wear resistant steel, high- strength - steel plate

Technical data :

Chemical Composition | ||||||

GRADE | C | Si | Mn | P | S | Ti |

SGCC/DX51D+Z | ≤0.10 | ≤0.50 | ≤0.60 | ≤0.10 | ≤0.030 | ≤0.020 |

DX52D+Z | ≤0.10 | ≤0.50 | ≤0.60 | ≤0.10 | ≤0.030 | ≤0.020 |

SGCD/DX53D+Z | ≤0.10 | ≤0.30 | ≤0.50 | ≤0.05 | ≤0.030 | ≤0.020 |

SGCE/DX54D+Z | ≤0.10 | ≤0.30 | ≤0.30 | ≤0.03 | ≤0.020 | ≤0.020 |

DX56D+Z | ≤0.10 | ≤0.30 | ≤0.30 | ≤0.03 | ≤0.020 | ≤0.020 |

Structural | ≤0.20 | ≤0.60 | ≤1.70 | ≤0.10 | ≤0.045 | |

hot dipped galvanized steel coil Mechanical Properties | |||

GRADE | Yield Strength MPa | Tensile Strength MPa | Elongation % |

SGCC(DX51D+Z) | ≥205 | ≥270 | - |

SGCD(DX53D+Z) | - | ≥270 | 38 |

SGCE(DX54D+Z) | - | ≥270 | 40 |

DX56D+Z | - | ≥270 | 42 |

- Q: How are steel coils used in the production of packaging machinery?

- Steel coils are used in the production of packaging machinery as they serve as the raw material for manufacturing various components of the machinery, such as frames, supports, and structural elements. The steel coils are processed through cutting, bending, and welding to create the necessary parts, ensuring durability and stability in the packaging machinery's construction.

- Q: Im getting a new guitar soon, and it has steel strings. ive heard that nilon strings are better? thanks:)

- Nylon strings aren't better The very notion of such is absurd. They're different. They sound different and feel different. Different guitars are designed for different types of strings. Nylon string guitars are most commonly associated with classical music (you'll never see a real classical musician play a steel string guitar) Whoever told you that nylon strings are better should be ignored altogether. They're obviously not a good source of information.

- Q: Can steel coils be transported by air?

- Yes, steel coils can be transported by air. Air freight companies have the capability to transport heavy and oversized cargo, including steel coils, using specialized aircraft and equipment. However, due to their weight and size, transporting steel coils by air can be more expensive compared to other modes of transportation such as sea or rail.

- Q: Is there a type of spray paint that would work on Stainless steel?That would also be permenant or at least make it through a wash or two?

- I've also learned something today! Good luck and have fun!

- Q: Can steel coils be used in architectural applications?

- Architectural applications can indeed utilize steel coils. These coils possess versatility and can be transformed into various shapes and forms to match the distinctive design specifications of architectural ventures. They find utility in constructing structures such as buildings, bridges, and more, as well as in fabricating architectural elements like roofing, cladding, and facades. The utilization of steel coils in architectural applications presents several benefits. They exhibit exceptional durability, strength, and corrosion resistance, rendering them suitable for constructing enduring and low-maintenance structures. Steel coils can be customized in terms of thickness, width, and surface finish, granting architects the ability to achieve their desired aesthetic and functional objectives. Moreover, steel coils are renowned for their structural stability and load-bearing capacity, both of which are vital considerations in architectural designs. Their high strength-to-weight ratio makes them an ideal selection for creating spacious and open interior areas, as well as for supporting heavy loads in multi-story buildings. Additionally, steel coils are easily fabricated and installed, resulting in time and labor savings during the construction process. They can be efficiently molded, cut, and welded to create intricate shapes or architectural details. Additionally, steel coils can be pre-fabricated off-site, guaranteeing precision and quality control, and subsequently assembled on-site, reducing construction time and minimizing disruptions to the surrounding environment. All in all, steel coils present architects and designers with a wide array of possibilities in architectural applications. Whether it pertains to structural support, aesthetic appeal, or functional requirements, steel coils provide a dependable and versatile material option that can fulfill the demands of contemporary architectural projects.

- Q: What are the different types of steel coatings for coils?

- Coils can be coated with various types of steel coatings, each with its own unique properties and advantages. Some of the most commonly used coatings include: 1. Galvanized Coating: This type of steel coating is widely utilized for coils. It involves applying a layer of zinc to the steel, which provides excellent protection against rust and corrosion. It is particularly suitable for outdoor applications or environments with high moisture levels. 2. Galvannealed Coating: Galvannealed steel coating involves subjecting the galvanized steel to additional heat treatment, resulting in a matte finish and improved adhesion for paint. It offers enhanced corrosion resistance and is often preferred in the automotive and construction sectors. 3. Aluminized Coating: Coating steel coils with aluminum provides outstanding heat resistance and corrosion protection. Aluminized steel is commonly employed in exhaust systems and other applications involving high temperatures. 4. Organic Coatings: Steel coils can also be coated with organic materials like paints or powder coatings. These coatings offer additional protection against corrosion and can be customized to meet specific aesthetic requirements, available in a wide range of colors. 5. Tin Coating: Tin-plated steel coils are covered with a layer of tin, which provides excellent solderability and resistance to corrosion. This type of coating is frequently used in the production of cans and other food packaging materials. 6. Phosphate Coating: Phosphate coatings are often applied as a pre-treatment before other coatings to enhance adhesion and corrosion resistance. They create a thin, crystalline layer on the steel surface, facilitating better adhesion of paint or powder coatings. These examples illustrate the diversity of steel coatings available for coils. The choice of coating depends on specific application requirements, considering factors such as corrosion resistance, heat resistance, paint adhesion, and aesthetic preferences.

- Q: What are the different methods of levelling steel coils?

- Different methods are employed to level steel coils, depending on their specific requirements and applications. Some commonly used methods include: 1. Roller Leveling: This method utilizes a series of rollers to apply pressure on the steel coil, effectively reducing residual stresses and eliminating any waviness or curvature. It is commonly used for achieving high flatness in thinner gauge coils. 2. Stretch Leveling: In this method, the steel coil is stretched beyond its yield point to eliminate shape defects. The coil is subjected to tension in a stretcher leveler machine, which elongates the material and removes inherent stresses. It is often used for achieving greater flatness in thicker gauge coils. 3. Temper Milling: This method involves passing the steel coil through a temper mill equipped with work rolls on top and bottom. The temper mill applies tension to the coil, flattening it and improving its shape and surface quality. It is typically used for higher strength steel grades. 4. Corrective Leveling: When the steel coil exhibits significant shape defects like wavy edges or center buckles, corrective leveling is employed. This method selectively removes material from specific areas of the coil to achieve a flat and uniform surface. Laser or plasma cutting machines are often used for this process. 5. Tension Leveling: Similar to stretch leveling, tension leveling applies tension to the coil without exceeding its yield point. Bridle rolls are used to stretch the material, eliminating internal stresses and leveling the coil. It is commonly used for achieving flatness in higher strength and thinner gauge coils. These methods can be used individually or in combination, depending on the specific requirements and desired end product. Each method has its advantages and limitations, and the choice of leveling method depends on factors such as coil thickness, material properties, and desired flatness.

- Q: I am planning to buy a Walther P22. I have liked the Pistol's performance-superb.The only confusion that I have is about the Polymer Frame.Just for this I may shift to someother manufacturer.Are Polymer Frames better than Steel in durability and lifespan.Walther says YES.Any comments on this...Practical users...Thanks in advance

- Walther P22 Frame

- Q: What are the different cutting methods for steel coils?

- There are several different cutting methods that can be used for steel coils, depending on the specific requirements and desired outcome. Some of the most common cutting methods for steel coils include: 1. Slitting: Slitting is a method that involves cutting the steel coil into narrower strips. This is typically done using a slitting machine that features multiple circular blades. The machine will unwind the coil and pass it through the blades, which will cut it into the desired width. Slitting is commonly used for applications that require narrower strips of steel, such as in the manufacturing of automotive parts or electrical appliances. 2. Shearing: Shearing is a cutting method that involves using a shear machine to cut through the steel coil. The machine will have a straight blade that is pressed against the coil, effectively cutting it into desired lengths or shapes. Shearing is often used for applications that require precise cuts or when the steel coil needs to be cut into specific sizes. 3. Laser cutting: Laser cutting is a more advanced cutting method that uses a high-powered laser to cut through the steel coil. The laser beam is directed onto the coil, melting or vaporizing the metal and creating a clean and accurate cut. Laser cutting is highly precise and can be used to cut intricate designs or patterns into the steel coil. It is often used in industries such as aerospace, automotive, and electronics. 4. Plasma cutting: Plasma cutting is a cutting method that uses a high-velocity jet of ionized gas to melt and remove the metal from the steel coil. The gas is usually a mixture of oxygen and an inert gas, such as nitrogen or argon. Plasma cutting is known for its speed and versatility, as it can cut through a variety of metals, including steel. It is often used in industries that require fast and efficient cutting, such as shipbuilding or construction. These are just a few of the different cutting methods that can be used for steel coils. The choice of method will depend on factors such as the desired outcome, the thickness of the steel coil, and the specific requirements of the application. It is important to consult with a professional or specialist to determine the most suitable cutting method for your specific needs.

- Q: Are steel coils susceptible to damage during storage or transportation?

- Yes, steel coils are susceptible to damage during storage or transportation. Factors such as mishandling, improper stacking, exposure to moisture or extreme temperatures, and inadequate packaging can lead to dents, scratches, corrosion, and even deformation of the coils. Adequate precautions and secure packaging are necessary to minimize the risk of damage during storage or transportation.

Send your message to us

GALVANIZED CORRUGATED STEEL

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords