Cold Rolled/Hot Dipped Galvanized Steel Coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

| Thickness | 0.12mm-3.5mm |

| Thickness tolerance | ±0.02mm |

| Width | 600--1500mm |

| Width tolerance | ±2mm |

| Length | 1-6m or in coil |

| Zinc coating | 40g/m2-275g/m2 |

| Types | Commercial / Drawing / Deep Drawing / Structural quality |

| Quality | Soft or hard quality |

| Standard | ASTM, AISI, DIN, GB,JIS |

| Material | SGCC, DX51D,DX52D, DX53D,SGCD , Q195, Q235, SGHC, DX54D, S350GD, S450GD, S550GD, etc |

| Spangle State | Regular spangle, small spangle, big spangle, non-spangle |

| Surface treatment | chromed / oiled/slightly oiled/ dry/ anti-fingerprint etc |

| Coil weight | 3-8ton or up to you |

| Coil ID: | 508 /610mm |

| Packing | Standard exportation packing |

| Min order | As per specification |

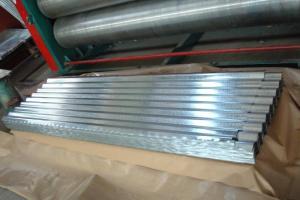

Product Picture

FAQ

1. Q: What's the MOQ?

A: Our MOQ is 25mt.

2. Q: What's the delivery time?

A: It will take about 30 days after TT or L/C.

3. Q: What is the payment terms?

A: T/T, L/C at sight

4. Q: How does your factory carry out quality control?

A: We attach great importance to quality control.Every part of our products has its own QC.

5. Q: What certificate do you have?

A: We have SGS, ISO9001 etc. Also we can apply any certificate if you need if the qty is OK.

- Q: Can steel coils be used in the production of aerospace components?

- Yes, steel coils can be used in the production of aerospace components. Steel is a durable and versatile material that offers excellent strength-to-weight ratio, making it suitable for various applications in the aerospace industry. Steel coils can be processed and shaped to meet specific requirements, such as forming intricate components, structural parts, or even for use in aerospace engines. Additionally, steel's corrosion resistance properties and ability to withstand high temperatures make it a reliable choice for aerospace applications.

- Q: How are steel coils packaged for transportation?

- Steel coils are typically packaged for transportation using a variety of methods to ensure their safe and secure delivery. The packaging process involves several steps to protect the coils from damage during transit and to facilitate their handling and loading onto trucks, ships, or trains. Firstly, steel coils are tightly wound and bound using steel straps or bands to keep them compact and prevent unwinding. These straps are usually made of high-strength steel and are securely fastened around the circumference of the coil at regular intervals. This helps to maintain the coil's shape and prevent any movement during transportation. Next, the coils are often placed on wooden or steel pallets to provide a stable base and facilitate handling with forklifts or cranes. The pallets are usually sized to fit the dimensions of the coils and are designed to withstand the weight and stress of the loaded coils. To provide additional protection, steel coils are often covered with a layer of protective material such as plastic or paper to shield them from moisture, dust, and other potential contaminants. This wrapping also helps to prevent scratching or damage to the outer surface of the coils. Furthermore, to secure the coils and prevent shifting during transit, they are often placed within a steel or wooden crate. These crates provide an extra layer of protection and stability, particularly for larger coils or when multiple coils are being transported together. Finally, once the coils are properly packaged, they are typically loaded onto flatbed trucks, shipping containers, or railway cars for transportation. During loading, proper care is taken to ensure that the coils are positioned securely and that weight distribution is balanced to prevent any potential damage or accidents during transit. In summary, steel coils are packaged for transportation by tightly binding them with steel straps, placing them on pallets, covering them with protective material, and, if necessary, enclosing them within crates. This packaging process helps to safeguard the coils and ensure their safe and efficient transportation to their destination.

- Q: can anyone help me to find any webpage about lists/types of stainless steel?

- Types of stainless steel There are over 150 grades of stainless steel, of which fifteen are most common. The AISI (American Iron and Steel Institute) defines the following grades among others: - 200 Series—austenitic iron-chromium-nickel-manganese alloys - 300 Series—austenitic iron-chromium-nickel alloys Type 301—highly ductile, for formed products. Also hardens rapidly during mechanical working. Type 303—free machining version of 304 via addition of sulfur Type 304—the most common; the classic 18/8 stainless steel Type 316—Alloy addition of molybdenum to prevent specific forms of corrosion - 400 Series—ferritic and martensitic alloys.

- Q: How are steel coils used in the oil and gas industry?

- Steel coils are used in the oil and gas industry for various purposes such as storage, transportation, and processing of oil and gas products. These coils are commonly used in the construction of pipelines, tanks, and equipment due to their strength, durability, and resistance to corrosion. They are also utilized in the production of offshore platforms and drilling rigs. Overall, steel coils play a crucial role in ensuring the efficient and safe extraction, transportation, and processing of oil and gas resources.

- Q: How do steel coils compare to other types of metal coils?

- Steel coils are generally considered superior to other types of metal coils due to their exceptional strength, durability, and versatility. Steel coils have excellent resistance to corrosion, heat, and impact, making them suitable for various applications ranging from construction and automotive industries to manufacturing and packaging sectors. Additionally, steel coils exhibit excellent formability and can be easily shaped and molded into different shapes and sizes, offering greater flexibility and customization options.

- Q: i would like to know of any companies who buy shredded scrap steel

- We are one of the biggest steel mills in Asia. Under our group, we have steel mills in Thailand and Bangladesh. On the monthly basis, we purchase steel scrap HMS1/2 80:20 and the shredded ISRI210/211, ISRI211 by bulk and 20' container to Thailand and Bangladesh. Due to the limitation of our existing shredded steel scrap supplier, we need to get more supply of the shredded. Please contact us or offer us of ISRI 210/211 or ISRI211 CFR Chittagong, Bangladesh with 500mt - 2000mt per shipment by 20' container. If any questions, please feel free to contact us.

- Q: How are steel coils used in the manufacturing of construction equipment?

- Steel coils are used in the manufacturing of construction equipment as they serve as a primary raw material for the fabrication of various structural components such as frames, bodies, and chassis. These coils are typically processed through cutting, bending, welding, and shaping techniques to create the necessary parts that provide strength, durability, and stability to construction machinery.

- Q: Can steel coils be used in architectural applications?

- Yes, steel coils can be used in architectural applications. Steel coils are commonly used in the construction industry due to their strength, durability, and versatility. They can be shaped, formed, and fabricated into various architectural components such as roofs, walls, facades, and structural elements. Additionally, steel coils can be coated or painted to enhance their aesthetic appeal and protect them from corrosion, making them a popular choice in architectural designs.

- Q: What are the common coil coating methods?

- The common coil coating methods include roll coating, spray coating, and coil coating with pre-painted metal substrates.

- Q: How are steel coils used in the manufacturing industry?

- Steel coils are used in the manufacturing industry for a variety of purposes, including the production of various steel products such as automotive parts, construction materials, household appliances, and machinery components. These coils are often processed and formed into desired shapes through techniques like cutting, bending, and welding to create finished products that are durable, strong, and suitable for various applications in different sectors.

Send your message to us

Cold Rolled/Hot Dipped Galvanized Steel Coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords