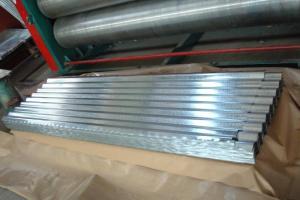

Cold Rolled Galvanized Steel Coil/Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

cold rolled steel coil description:

Standard:AISI,ASTM,BS,GB,JIS

Grade:SPCC

Thickness:0.15mm-0.8mm

Type:Steel Coil

Technique:Hot Rolled

Surface Treatment:Galvanized

Width:600mm-1250mm

Specifications:

Cold rolled galvanized steel coil/plate

1.Uniform thickness galvanized steel coil

2.Best service

3.high quality low price

Cold rolled galvanized steel coil/plate

1.Uniform thickness galvanized steel coil

2.Best service

3.high quality low price and fast delivery

4.zinc coating:60g-150g/m² or as you request

Appcations of Galvanized steel coil/palte

1.Buildings and constructions: roofing, ceilings, gutters, venting lines, indoor decorations, window frames, etc

2.Electrical appliances: computer shells, washing machines, refrigerators, dehumidifiers, video recorders, water heaters, etc.

3. Agricultural equipments: troughs, feeding tools, agricultural driers, irrigation channels, etc.

4. Vehicle parts: back-seat plates of buses and trucks, conveying systems, oil tanks,etc

FAQ:

Acceptable payment term and way?

T/T,L/C, T/T + L/C, D/P

Acceptable price term

FOB CNF CIF DDU CPT

Do you accept OA payment terms?

Yes, sure, but it normally depending on the order value

Do you have QC team?

Yeah, sure, our QC team is very important, they will keep the qualitycontrol for our products.

What is the validity of your quotation?

Normally 7 days.

What is your advantage?

24 hour quick response /Customer oriented/ Credit foremost/ Top quality Excellent

What is your acceptable payment term?

TT,LC,OA etc

- Q: Hello,is it possible to divide an alloy in its own elements? I am particularly interested in Stainless Steel, which is made of Nickel, Chrome and Iron. Do you have an idea of where can I find some more information (blogs, reviews, sites or books)?Thanks for your help

- Yes it is possible to recover individual elements from an alloy such as stainless steel, but not easy. Look up etching of stainless steel on google. This same etching solution will completely dissolve stainless steel. These solutions are strong acids such as H2SO4 and HNO3 so safety goggles and good ventilation are absolutely required. Once the metal has been dissolved, then you would need to use a qualitative analysis scheme to precipitate out the different metals one at a time as compounds, then do additional reactions to recover the metallic elements.

- Q: i need this for school and i need to know what are some advantages of stainless steel.

- It is great for knives because it stays chromed looking without rust. The steel is very hard so holds an edge for a long time. If it contains enough nickel it also is not magnetic, which some applications need this trait It is used for exhaust pipes in good cars, because it doesn't corrode from exhaust like common steel will, so the exhaust pipes last very long. Stainless is used for sinks, ovens, and kitchen appliances because it holds a shine, is very durable , doesn't crack or get burn holes like plastic would. It doesn't rust and is easy to clean and has a good color. It is used on exterior building panels for the same reason , plus it adds the same structural strength as regular steel without the maintenance of painting and rust removal. It is great for pans because you can scrub it without scraping it and it conducts heat well and cleans easily because the surface is smooth and hard So it has the same advantages of strength and fabrication as regular steel, without the downside of rust and ugliness. More cost (it contains chromium and nickel which are expensive) and harder to weld is two of it's shortcomings

- Q: doesnt steel rust?

- ferrous metals rust

- Q: If you were selecting a tool steel for an extreme impact load application, which one would you pick? why?thanks

- It all depends what the application actually is. For hammers I would select a hammer grade B1 steel. For impact loading where an edge is needed I would be going for O1 or similar (oil quenching steels tend to be a little tougher than air hardening). For mining tools a very high manganese steel (Hadfields steel) - this is not a true tool steel. The best place to start is by looking at the ranking of the properties which you want - hardness v toughness v strength - and then use this to put the steels in rank order. Price and availablity then sort the problem out for you (in the real world).

- Q: Will a 1 inch thick A36 steel target withstand a 7.62x54r round?

- Yes, most definitely. Just make sure it's full and don't have air inside lol. You can tell it's full by it being heavy. I've seen bullet tests on TV and I'm like 100% positive it's gonna withstand. But no, you can't use it as bullet-proof vest, because it's HEAVY!! You can see on Youtube. 1 inch legitimate steel would stop even a 50 cal

- Q: But we've had a problem with bears being attracted to the water in the Intex Inflatable pools, the bear would come at night every so often and push on the sides letting out the water.Would a bear be able to bend a steel frame before I go and spend money?

- depends how thick the steel is. Looking at it, I would say yes. Not the frame pieces, but just the walls of the pool.

- Q: What are the advantages of using steel coils in the manufacturing industry?

- Using steel coils in the manufacturing industry offers several advantages. Firstly, steel coils are renowned for their strength and durability, making them an ideal choice for various manufacturing processes. They can withstand heavy loads and resist deformation, ensuring that the final product is reliable and long-lasting. Secondly, steel coils are highly versatile and can be used in a wide range of applications across different industries. They can be shaped, molded, or cut into different forms and sizes, catering to diverse manufacturing needs. Additionally, steel coils are cost-effective. Their strength and durability result in a longer lifespan compared to other materials, reducing the need for frequent replacements and leading to cost savings in the long run. Furthermore, steel coils have excellent thermal conductivity, meaning they can efficiently transfer heat. This makes them suitable for applications that require temperature regulation, such as in the automotive and HVAC industries. Moreover, using steel coils in the manufacturing process contributes to a more sustainable and eco-friendly approach. Steel is one of the most recycled materials globally, reducing the need for raw materials extraction and energy consumption, and resulting in a reduced carbon footprint. Furthermore, steel coils can be coated with protective layers to enhance their resistance to rust and corrosion. This makes them suitable for outdoor applications or industries with corrosive environments. Lastly, steel coils offer consistent quality and uniformity in terms of dimensions, mechanical properties, and surface finish. This ensures that the end products meet the required specifications and maintain a high level of quality. To summarize, the advantages of using steel coils in the manufacturing industry include their strength, durability, versatility, cost-effectiveness, excellent thermal conductivity, recyclability, corrosion resistance, and consistent quality. These benefits make steel coils a popular choice for various manufacturing processes across different industries.

- Q: How are steel coils used in the manufacturing of industrial mixers?

- Steel coils are used in the manufacturing of industrial mixers as they provide a strong and durable structure for the mixer body. The coils are shaped and welded to create the necessary components, such as the mixing chamber and blade supports. This ensures that the mixer can withstand the high forces and vibrations involved in mixing large quantities of materials in industrial applications.

- Q: I want to purchase a set of knives made of carbon steel and want to be able to store them on a magnetic knife strip for handy access, I just wasn't sure if this alloy would stick to a magnet????Thanks

- Carbon steel knives will stick to a magnet. Stainless steel may not.

- Q: Cold rolled steel coil steel, what is the difference?

- Cold: hot rolled steel coil as raw material by pickling descaling after cold rolling, the finished rolling hard volumes, due to continuous deformation caused by cold hardening the volume rolling hard strength, hardness, toughness index rise decline, so the stamping performance will deteriorate, only for a simple deformation of parts. Rolled hard rolls can be used as raw material for hot galvanizing plants. Because the hot galvanizing units are equipped with annealing lines, the steel coils are rolled continuously at room temperature. Its strength is very high, but toughness, weldability is slightly worse, bright surface, not easy to corrosion, in order to prevent rust, the factory surface is coated with a protective layer of oil (hot rolling did not). Because of the complexity of the process, the price is higher.

Send your message to us

Cold Rolled Galvanized Steel Coil/Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords