Thickness: 0.15 - 2.0 mm

Technique: Hot Rolled

Application: Container Plate

Surface Treatment: Galvanized

Secondary Or Not: Non-secondary

Certification: CE

Special Pipe: Thick Wall Pipe

Alloy Or Not: Non-alloy

Section Shape: Other

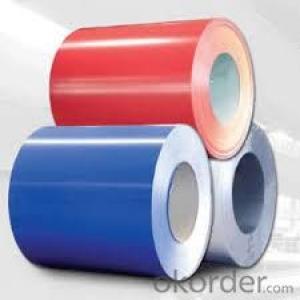

Galvanized Steel Coil Hold Rolled DX51+D CNBM

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Quick Details:

2.Packaging & Delivery

| Packaging Details: | standard package |

|---|---|

| Delivery Detail: | 1-4 week |

cold rolled galvanizing steel coil

galvanized iron steel coil

Thickness | 0.15mm--2.0mm |

Width | 50--1250mm |

Zinc Coating | 40gsm—275gsm |

Spangle | Big, small regular spangle and zero spangle |

Surface Treatment | Chromate, Galvanized, Skin Pass, Passivity and Oiled(un-oiled) |

ID | 508mm or 610mm |

Coil Weight | 3--7 Metric Tons and as requirements |

Production | 12,000 metric tons per month |

More information of Galvanized Steel Coils/GI/PPGI/HDG | |

Payment Term | T/T or L/C (We usually charge 30% of the deposit first.) |

Delivery Port | Qingdao Port or Tianjin Port |

Delivery Time | Within 20 days after receipt of T/T or L/C |

MOQ | 25 metric tons or one 20 feet container |

Application | General use, Color coating, Corrugated Roofing making, Outside of the buildings Structure, Deep Drawing and etc. |

Ambition | Reliable product, Competitive price, On-time delivery and High standard service. |

5.What is the application of Steel Coil?

There are two sides,one is out side: Workshop, agricultural warehouse, residential precast unit, corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth;the other is inside: Door, doorcase, light steel roof structure, folding screen, elevator, stairway, vent gutter.

- Q: What are the quality control measures for steel coils?

- Quality control measures for steel coils typically include various inspections and tests to ensure that the coils meet the required standards and specifications. These measures often involve visual inspections to identify any surface defects or irregularities, such as cracks, dents, or scratches. Additionally, dimensional checks are performed to verify the coil's size, shape, and weight. Other quality control measures may involve conducting mechanical tests, such as tensile strength and hardness tests, to assess the strength and durability of the steel coils. Overall, these measures aim to guarantee that the steel coils are of high quality and suitable for their intended applications.

- Q: How can I judge the quality of steel?

- The quality of the alloy can be very well be judged by its appearance and lustrous surface. The more luster on the surface the more refine will the steel be. To judge its tenacity and endurance, the alloy can be subjected to a series of procedures involving stress and shock. There are many more scientific methods of measuring the quality of the alloy such as texture measurement technique etc are also employed. In layman’s term the quality can be measured by the hardness of surface, brightness and smoothness of the surface and absence of any depressions or troughs.

- Q: What are the different types of steel coil surface treatments for corrosion resistance?

- There are several different types of steel coil surface treatments that are used to enhance corrosion resistance. These treatments are applied to the surface of the steel coil to create a protective layer that prevents corrosion and extends the lifespan of the steel. Some of the common types of surface treatments for corrosion resistance include: 1. Galvanizing: This is one of the most popular and effective methods for protecting steel against corrosion. In this process, a layer of zinc is applied to the surface of the steel coil. The zinc acts as a sacrificial anode, corroding before the steel does, thus protecting it from rust and corrosion. 2. Chromate conversion coating: This treatment involves applying a chromate-based solution to the surface of the steel coil. The chromate forms a thin film on the steel, providing a protective barrier against corrosion. It also enhances the adhesion of paint or other coatings that may be applied later. 3. Phosphating: Phosphating is a process where a phosphate coating is applied to the steel coil. This coating provides excellent corrosion resistance by forming a chemical bond with the steel surface. It also improves the adhesion of subsequent coatings or paints. 4. Organic coatings: These coatings, such as paint or epoxy, are applied to the steel coil to create a barrier between the steel and the surrounding environment. They provide both corrosion resistance and aesthetic appeal. The choice of organic coating depends on the specific application and the desired level of corrosion protection. 5. Zinc-rich paint: Similar to galvanizing, zinc-rich paint contains a high concentration of zinc particles. When applied to the steel coil, the zinc particles provide sacrificial protection, preventing corrosion. This coating is often used in harsh environments or for steel coils that will be exposed to frequent moisture or saltwater. It is important to note that the choice of surface treatment depends on various factors such as the application, environment, budget, and required level of corrosion resistance. Consulting with a steel coil manufacturer or corrosion specialist is recommended to determine the most suitable treatment for a specific situation.

- Q: What are the different methods of annealing steel coils?

- There are several different methods of annealing steel coils, each with its own advantages and applications. The main methods include full annealing, process annealing, and spheroidize annealing. Full annealing is the most common method and involves heating the steel coils to a temperature above its critical point, typically between 800 and 900 degrees Celsius (1472 and 1652 degrees Fahrenheit), and then slowly cooling it down in a controlled manner. This process helps to refine the grain structure of the steel, making it softer and more ductile. Full annealing is often used to relieve internal stresses, improve machinability, and enhance the overall mechanical properties of the steel. Process annealing, also known as subcritical annealing or stress relief annealing, is a method used to reduce the hardness and brittleness of steel coils. It involves heating the coils to a temperature below its critical point, typically between 550 and 650 degrees Celsius (1022 and 1202 degrees Fahrenheit), and then slowly cooling them down. This process helps to relieve internal stresses that may have developed during previous manufacturing processes, such as cold working or welding. Process annealing is commonly used to improve the formability and toughness of steel coils. Spheroidize annealing is a specific type of annealing that is used to soften high carbon and alloy steels. It involves heating the steel coils to a temperature slightly below its critical point, typically between 650 and 700 degrees Celsius (1202 and 1292 degrees Fahrenheit), and then holding it at that temperature for a prolonged period of time. This allows the carbides within the steel to transform into rounded or spheroidal shapes, which increases the steel's machinability and ductility. Spheroidize annealing is often employed in the production of cutting tools, bearings, and other applications where improved machinability is desired. In addition to these main methods, there are also variations and specialized techniques that can be used for specific purposes, such as recrystallization annealing, intercritical annealing, and solution annealing. Each method has its own set of parameters and temperature ranges, and the choice of annealing method depends on factors such as the type of steel, desired mechanical properties, and the intended application of the steel coils.

- Q: What are the different coil leveling line configurations used for steel coils?

- The steel industry utilizes various coil leveling line configurations to meet specific requirements and preferences. Some commonly employed configurations include: 1. Straightener: Employed to rectify coil shape defects or distortion. It consists of rollers that gradually straighten the coil. 2. Leveler: Ensures consistent thickness throughout the coil. Utilizes rollers to flatten the coil to the desired thickness. 3. Combination Straightener/Leveler: Integrates both straightening and leveling functions into a single machine. Combines rollers and straightening elements for shape correction and thickness leveling in one pass. 4. Looping Pit: Allows continuous processing of accumulated coils. Serves as a buffer between the entry and exit sections of the leveling line, accommodating variations in coil supply and demand. 5. Tension Leveler: Applies tension during leveling to remove shape defects and achieve a flat, uniform surface. 6. Rotary Shear: Incorporates a synchronized rotary shear to cut the leveled coil accurately and precisely. These examples showcase the diverse coil leveling line configurations used in the steel industry. The choice of configuration depends on factors such as desired product specifications, coil dimensions, processing speed requirements, and budget considerations.

- Q: What are the common defects found in steel coils?

- Some common defects found in steel coils include surface defects such as scratches, pits, or dents, as well as edge defects like burrs or cracks. Other defects can include coil set or crossbow, which refers to the shape of the coil being out of alignment or having a curved shape. Additionally, defects such as oil or rust stains, laminations, or variations in thickness can also be found in steel coils.

- Q: What are the different types of steel coil coatings for heat resistance?

- Heat resistance is achieved through the use of different types of steel coil coatings. These coatings are designed specifically to safeguard the steel surface, preventing it from deteriorating or oxidizing under high temperatures. Organic coatings, such as epoxy, polyester, or polyurethane, are commonly used. They form a protective barrier against heat and prevent the steel from corroding or oxidizing. Organic coatings are typically employed in situations where moderate heat resistance is necessary. Another option is inorganic coatings, made from ceramic or metallic materials. These coatings offer excellent heat resistance and can endure extremely high temperatures. Industries like automotive, aerospace, and power generation frequently utilize inorganic coatings, as their components are exposed to intense heat. Specialized coatings are also available to meet specific heat resistance requirements. Silicone coatings, for instance, exhibit exceptional heat resistance and can withstand temperatures reaching 600°C (1112°F). They find common use in applications like exhaust systems, ovens, and industrial furnaces. Some steel coil coatings may also incorporate additives or fillers to enhance their heat resistance properties. These additions improve the coating's ability to withstand high temperatures and provide superior protection against heat-related issues. In conclusion, a range of steel coil coatings is available for heat resistance, including organic coatings, inorganic coatings, and specialized coatings. The choice of coating depends on the specific heat resistance requirements of the application. Factors such as temperature range, duration of exposure, and environmental conditions must be taken into account when selecting the appropriate coating.

- Q: How are steel coils inspected for thickness variations?

- Steel coils are inspected for thickness variations using non-contact laser measurement systems. These systems use laser sensors to scan the surface of the coil and measure the distance between the sensor and the coil at multiple points. The data collected is then analyzed to identify any variations in thickness, allowing for quality control and ensuring compliance with desired specifications.

- Q: Can i use steel shot in a remington 870 wingmaster full choke 30 inch barrel. the shotgun is in great shape and about 20 or 25 years old probably. thank you. the steel shot i have got is 12 gauge 2 3/4 in 1550 velocity 1 1/16 oz 2 shot winchester xpert high velocity steel shot

- Because of environmental concerns steel, bismuth and tungsten is replacing lead shot, for bird hunting. The problem with steel shot is the hardness, which can cause damage to the bore and choke in older shotguns. Unlike lead there is no give to steel and it can damage the bore especially if the choke is on full. Tungsten is also very hard, but it is often alloyed with other metals making it softer causing less damage in older models shotguns. Bismuth falls in between tungsten and steel, being the softer of the two by far.

- Q: a steel abr sells for about 879 now...a mith just over 1kany suggestions on which-keyword WHICH steel item to make-which is the best-exp wise, and steel bar conservative wise.

- If members, cannonballs. If not, steel kites, I suppose. Steel Platebody only alchs for 1200, and requires 5 bars... But I stuck with steel, till 70 smithing... cheaper, and requires less coal to make....

Send your message to us

Galvanized Steel Coil Hold Rolled DX51+D CNBM

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords