Thickness: 0.15 - 2.0 mm

Technique: Hot Rolled

Application: Container Plate

Surface Treatment: Galvanized

Secondary Or Not: Non-secondary

Certification: CE

Special Pipe: Thick Wall Pipe

Alloy Or Not: Non-alloy

Section Shape: Other

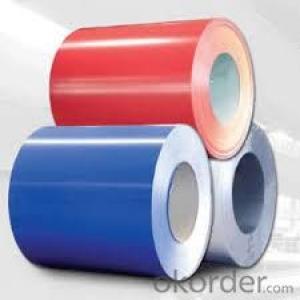

Galvanized Steel Coil Cold Rolled Dx51d CNBM

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Quick Details:

2.Packaging & Delivery

| Packaging Details: | standard package |

|---|---|

| Delivery Detail: | 1-4 week |

cold rolled galvanizing steel coil

galvanized iron steel coil

Thickness | 0.15mm--2.0mm |

Width | 50--1250mm |

Zinc Coating | 40gsm—275gsm |

Spangle | Big, small regular spangle and zero spangle |

Surface Treatment | Chromate, Galvanized, Skin Pass, Passivity and Oiled(un-oiled) |

ID | 508mm or 610mm |

Coil Weight | 3--7 Metric Tons and as requirements |

Production | 12,000 metric tons per month |

More information of Galvanized Steel Coils/GI/PPGI/HDG | |

Payment Term | T/T or L/C (We usually charge 30% of the deposit first.) |

Delivery Port | Qingdao Port or Tianjin Port |

Delivery Time | Within 20 days after receipt of T/T or L/C |

MOQ | 25 metric tons or one 20 feet container |

Application | General use, Color coating, Corrugated Roofing making, Outside of the buildings Structure, Deep Drawing and etc. |

Ambition | Reliable product, Competitive price, On-time delivery and High standard service. |

5.What is the application of Steel Coil?

There are two sides,one is out side: Workshop, agricultural warehouse, residential precast unit, corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth;the other is inside: Door, doorcase, light steel roof structure, folding screen, elevator, stairway, vent gutter.

- Q: Ok I know this sounds stupid but is there anyway to make stainless steel look older? It looks too new and I don't want it like that. Thanks.

- Its called stainless for a reason :) many grades are out there, 300 400 series. You could use acid to make it look older but you wouldnt want to cook with it after chemically converting it with acid.Personally i like cast iron. It will last a life time + and looks very cool. Sorry no safe way to do it and cook with it. B^

- Q: were iron age weapons made of steel?

- No, the iron age was just iron. It was smelted down in open fires where temperatures can vary. There was a problem of not always being able to cook out all the impurities from the ore, which led to inconsistent strengths in finished products. People first discovered the properties and advantages of steel when charcoal (carbon) was added to smelted iron. I don't know when the first steel was made. But it must have been a more expensive process because it didn't appear in household products until around 1800. But I'm not sure on that.

- Q: How can I tell the wear resistance, strength, ect from the name of the steel?how could I tell the difference between 420 and 440 steel. what does the HC in 420 HC steel mean? what do the numbers and letters in s30v steel mean?

- Larry gave a good answer. As for the HC, it means High Carbon.

- Q: How are steel coils inspected for color consistency using colorimetry?

- Steel coils can be inspected for color consistency using colorimetry, which is a method of quantifying and measuring colors. Colorimetry involves the use of specialized instruments, such as spectrophotometers or colorimeters, to measure the color of an object in terms of its hue, saturation, and brightness. To inspect steel coils for color consistency, a colorimeter is typically used. This device emits light onto the surface of the steel coil and measures the amount of light reflected back. The reflected light is then analyzed and compared to a known standard color to determine if there are any deviations. The colorimeter measures color by breaking down the reflected light into different wavelengths and quantifying the intensity of each wavelength. This data is then converted into numerical values that represent the color of the steel coil. These numerical values can be compared to a predefined color standard to determine if the color of the coil falls within an acceptable range. To ensure accurate and consistent color measurement, colorimetry relies on standardized color spaces, such as CIE L*a*b* or CIE RGB, which define a specific range of colors. By using these standardized color spaces, colorimeters can provide objective and reliable measurements of color consistency. In the case of steel coils, color consistency is particularly important for industries where the appearance of the final product is crucial, such as automotive or appliance manufacturing. By inspecting the color of steel coils using colorimetry, manufacturers can ensure that the final products have a consistent and visually appealing appearance. Overall, colorimetry is an effective method for inspecting steel coils for color consistency. By using specialized instruments and standardized color spaces, manufacturers can accurately measure and compare the color of steel coils to predefined standards, ensuring that the final products meet the desired color specifications.

- Q: What are the common standards and specifications for steel coils?

- The common standards and specifications for steel coils include ASTM A36/A36M, ASTM A572/A572M, ASTM A1011/A1011M, and ASTM A653/A653M. These standards outline the requirements for the chemical composition, mechanical properties, dimensions, and other characteristics of steel coils used in various industries, such as construction, automotive, and manufacturing. Additionally, international standards like EN 10025 and JIS G3101 are also commonly followed in different regions.

- Q: How are steel coils processed and shaped into various products?

- Steel coils are processed and shaped into various products through a series of manufacturing processes. First, the steel coil is uncoiled and cleaned to remove any impurities. Then, it goes through a process called leveling, where the coil is flattened and straightened. Next, the steel is cut into the desired length or shape, using techniques like shearing or slitting. After that, it may undergo additional processes such as forming, bending, or rolling to give it the desired shape. Finally, the steel is often treated with coatings or finishes to enhance its durability and appearance.

- Q: How do steel coil manufacturers manage inventory?

- Steel coil manufacturers manage inventory by implementing various strategies and techniques. Firstly, they maintain a robust forecasting system to accurately predict demand and plan production accordingly. This helps in avoiding overproduction or stockouts. Additionally, they establish strong relationships with suppliers to ensure a steady supply of raw materials and reduce lead times. Inventory is carefully monitored using inventory management software, which tracks stock levels, identifies slow-moving or obsolete inventory, and enables timely reordering. Just-in-time (JIT) or lean manufacturing techniques are often employed to minimize inventory holding costs. Lastly, regular inventory audits and analysis are conducted to identify areas for improvement and optimize inventory levels for maximum efficiency and profitability.

- Q: How are steel coils tested for compliance with industry standards?

- Steel coils are tested for compliance with industry standards through a series of rigorous quality control measures. These tests are conducted to ensure that the coils meet the necessary specifications and are suitable for use in various applications. One of the primary tests performed on steel coils is the dimensional inspection. This involves measuring the thickness, width, and length of the coils to ensure they meet the specified tolerances. Any deviations from the required dimensions can indicate a manufacturing defect or potential issues during fabrication. Another critical test is the visual inspection, where trained inspectors carefully examine the coils for any surface defects such as scratches, dents, or cracks. These defects can affect the performance and durability of the steel coils, making it essential to identify and rectify them before they are supplied to customers. Furthermore, mechanical properties testing is conducted to assess the strength, elasticity, and toughness of the steel coils. This includes tests like tensile strength, yield strength, and elongation measurements. These tests help determine the suitability of the coils for specific applications and ensure they meet the required performance standards. Additionally, chemical composition analysis is performed to verify the elemental composition of the steel coils. This analysis is crucial as it ensures that the steel meets the required chemical requirements, including the presence of specific alloying elements. Deviations in composition can impact the overall quality and performance of the coils. Corrosion resistance testing is also important, especially for coils used in environments with high humidity or exposure to corrosive substances. Coils are subjected to salt spray or humidity chambers to simulate real-world conditions and evaluate their resistance to corrosion. Lastly, various non-destructive testing techniques, such as ultrasonic testing and magnetic particle inspection, are used to detect internal defects or discontinuities in the steel coils. These tests help identify any hidden flaws that may compromise the structural integrity of the coils. Overall, steel coils undergo a comprehensive range of tests to ensure compliance with industry standards. By conducting these tests, manufacturers can guarantee that the coils meet the required specifications, providing customers with high-quality products that meet their specific needs.

- Q: How is steel different than iron?How many different kinds of steel are there?What type is the strongest?Which type is the weakest?

- steel has carbon in it instead of just iron there are hundreds if not thousands of different kinds of steel for different applications strength depends on the definition. some have stronger tensile (pull) strength than others.

- Q: I love the design! It looks great, is safe, and you can see through it just fine on camera. Do you like it?BQ: Old Blue WWF Steel Cage or the newer fence type steel cage?

- yes it is better now

Send your message to us

Galvanized Steel Coil Cold Rolled Dx51d CNBM

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords