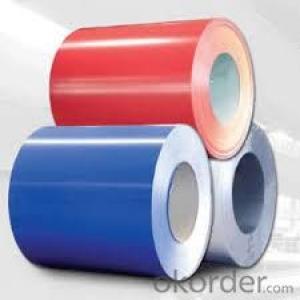

Prepainted Galvanized Rolled Steel Coil-DX51D in CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

description

prepainted galvanized steel usually refers to have substrateprocessed with surface processed and coated then(roller coated )or bonded organic thin film and baked, and it is able to be processed tofinal prodevtion .

prepaintedgalvanized steel qualified with excellent decorative ,formability ,corrosionresistance ,coating adhesion ,can keep for a long time as well as maintainfresh color .for color coated steel sheet can obtain good economicbenefit by steel belt wood ,efficient in construction and save energy ,preventpollution etc.which is an ideal material;for manufacturing board.

main features of the galvanized rolled steel

1. low moq: we will do our best to make you satisfied.

2.good service : we treat clients as friend.

3.good quality :we have strict quality control system .good reputation in the market.

4.fast & cheap delivery: we have big discount from forwarder (long contract).

5.supply ability: 50000 ton monthly

specification

yield strength | (mpa) 280-320 |

tensile strength | (mpa) 340-390 |

elongation | 20%-30% |

reverse impact | 9j |

t-bending | ≥2t |

pencil hardness | ≥2h |

duration of salt spray test | 500 h |

bending at 180 degree | no crack, purling and fraction |

image

applications ofprepainted galvanized steel

it can be widely used in transportation, light industry, civil usage and farming. it is also the perfect building material in construction for making steel roofing,insulation panel, corrugate sheet, facade wall,shutters,t-bar and home appliance.

- Q: How are steel coils used in the manufacturing of mining equipment?

- Steel coils are used in the manufacturing of mining equipment for various purposes, such as forming the structural components, building frames, and creating durable and robust machinery. These coils are often shaped, cut, and welded to construct mining machinery that can withstand the harsh conditions and heavy-duty operations in the mining industry.

- Q: How are steel coils priced and traded in the market?

- Steel coils are typically priced and traded in the market based on various factors such as the current demand and supply, raw material costs, production costs, and market competition. Steel coil pricing often takes into account the specifications of the coil, including its size, thickness, width, and grade. Additionally, market dynamics, such as global economic conditions, trade policies, and currency fluctuations, can also influence steel coil pricing. Traders and buyers negotiate prices based on these factors, and the final price is determined through a combination of supply and demand dynamics and market forces.

- Q: How are steel coils used in the construction of bridges?

- Steel coils are indispensable in the construction of bridges, as they are typically crafted from high-strength steel and serve various purposes throughout the bridge-building process. One of the primary functions of steel coils in bridge construction lies in the production of structural components. These coils are cut, shaped, and welded together to form beams, columns, and trusses, thus ensuring the bridge's stability and durability. Moreover, steel coils are employed in fabricating bridge decks, which serve as the upper surface of the bridge, providing a pathway for vehicles and pedestrians. The coils are rolled into sheets and further processed to create the deck plates, which are then assembled and attached to the bridge's structural elements. Another significant application of steel coils in bridge construction involves reinforcing concrete structures. Rebar, derived from steel coils, is embedded within the concrete to enhance its strength and resistance to tension. Strategically placed in locations such as bridge piers and abutments, the rebar provides additional support, preventing cracking or collapse. Furthermore, steel coils find utility in the manufacturing of bridge expansion joints. These vital components allow bridges to expand and contract in response to temperature fluctuations and external factors. By shaping steel coils into plates or strips, expansion joints can be easily installed and adjusted to accommodate the bridge's movement. To summarize, steel coils play a vital role in the construction of bridges, contributing to the manufacturing of structural components, bridge decks, reinforcing concrete structures, and expansion joints. With their strength and support, steel coils facilitate the creation of safe and reliable bridges, capable of withstanding diverse loads and environmental conditions.

- Q: What are the common coil thickness and width combinations available for steel coils?

- The common coil thickness and width combinations available for steel coils vary based on industry standards and specific requirements. However, some commonly available combinations include coil thicknesses ranging from 0.5mm to 3mm and coil widths ranging from 600mm to 1500mm. Ultimately, the specific thickness and width combination for steel coils will depend on the intended application and manufacturing capabilities.

- Q: What is the minimum diameter of a steel coil?

- The minimum diameter of a steel coil can vary depending on the specific manufacturing process and desired application. However, in general, the minimum diameter of a steel coil is determined by factors such as the thickness of the steel and the capabilities of the equipment used in the manufacturing process.

- Q: for instance Cr-Ni steeldoes this refer to plated steel or a uniform mixture

- stainless steel is an alloy normally iron with additions of C, Mn, Ni, Cr, and Nb - amounts added depend on properties required. Corrosion resistance is due to a very thin but dense layer of chromium oxide which forms at the surface and prevents further attack. Ordinary steel on the other hand becomes coated with a porous layer of iron oxide(rust) through which the atmosphere can pass and cause further corrosion.

- Q: Can steel coils be customized in terms of size and specifications?

- Certainly! Steel coils can indeed be personalized in terms of size and specifications. Although steel coils are normally produced in standard sizes and specifications, they can be customized to fulfill particular requirements based on the customer's preferences. Customization may involve altering the dimensions of the coils in terms of width, length, and thickness, as well as modifying specifications such as the type of steel, surface finish, and coating. Through this process, steel coils can be tailored to suit various applications and industries, ensuring that they meet the specific requirements and performance standards of customers. Industries such as automotive, construction, manufacturing, and appliances often utilize customized steel coils, as precise sizes and specifications are essential for efficient and effective operations.

- Q: Can steel coils be coated with fire-resistant materials?

- Yes, steel coils can be coated with fire-resistant materials.

- Q: How are steel coils used in the production of furniture components?

- Steel coils are commonly used in the production of furniture components as they provide a strong and durable material for construction. These coils can be shaped, cut, and formed into various components such as frames, supports, and brackets, adding strength and stability to the furniture. Additionally, steel coils can be coated or painted to enhance their appearance and protect against corrosion, making them versatile and long-lasting materials for furniture manufacturing.

- Q: I have a set of steel pans with copper bottoms. When I cook with oil it always burns the oil to the pan and takes days to clean. I don't think I should use steel wool, since it might scratch the surface. Does anyone know a faster way to clean scorched oil off a steel pan?

- Get a can of Barkeeper's Friend. It's a powdered cleanser. It's gentle enough to be used on a ceramic cook top but still strong enough to get metal clean. Cheap and made from rhubarb leaves! Dampen the pan with water, sprinkle generously and smear around with a sponge with one of those non-stick safe nylon scrub pads. Wait about 10-15 minutes to let the product do some of the work for you. Come back and give it a good scrub. Reapply if necessary. I have all stainless steel cookware and use the Barkeeper's to keep them looking nice; especially since they are on display with my pot rack. I also have some copper pieces used for decoration and I use the Barkeeper's to keep them looking nice. It cleans them up faster and better than any of the homemade concoctions or metal cleaners without the residue. And I do use it on my ceramic cook top too! Be sure to wash and rinse the pan after you get it clean; it does leave a haze if you don't.

Send your message to us

Prepainted Galvanized Rolled Steel Coil-DX51D in CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords