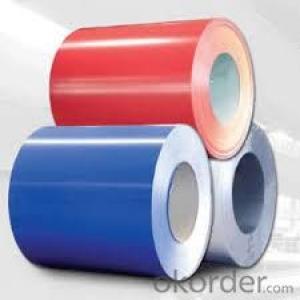

Prepainted Galvanized Rolled steel DX51D in CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

prepainted galvanized steel usually refers to have substrateprocessed with surface processed and coated then(roller coated )or bonded organic thin film and baked, and it is able to be processed tofinal prodevtion .

specification

yield strength | (mpa) 280-320 |

tensile strength | (mpa) 340-390 |

elongation | 20%-30% |

reverse impact | 9j |

t-bending | ≥2t |

pencil hardness | ≥2h |

duration of salt spray test | 500 h |

bending at 180 degree | no crack, purling and fraction |

Applications of Prepainted Galvanized Steel

It can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making steel roofing, insulation panel, corrugate sheet, facade wall, shutters, T-bar and home appliance.

Packaging & Delivery of Prepainted Galvanized Steel

The packing of coils consists of anti-damp paper, PVC film, hardboard paper, steel box, strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye to the side) or wooden pallets(eye to the sky).

image

- Q: I have heard using the BRASS casing is the best thing for an AR-15? Should i just use Brass or Steel?

- No. People who say that don't use steel cased ammo. It it said its harder on the extractor. I don't see how. Its dirtier because it doesn't expand like brass does but the steel casing is still softer than the steel of the gun. That is a mild steel which isn't as hard as what most people are thinking of.

- Q: I want to get a new knife but i cant decide if i wan a spyderco pacific salt or a cold steel ak47

- What exactly are you using it for? Personally I would go with Cold Steel AK47. It's a good all around knife for hunting, combat, stabbing and slashing as well as everyday use. Well balanced tip and very little bladeplay which can be a problem with a cheaper knife. Both are good companies but the CS AK47 wins hands down for me.

- Q: How do steel coils contribute to the manufacturing of household appliances?

- Steel coils contribute to the manufacturing of household appliances by providing a durable and versatile material for various components. These coils are used to create the outer casings, frames, and structural parts of appliances like refrigerators, washing machines, and dishwashers. The strength and flexibility of steel coils ensure the longevity and stability of these appliances, while also enabling manufacturers to create sleek and attractive designs.

- Q: How are steel coils used in the manufacturing of steel drums?

- Steel coils are used in the manufacturing of steel drums by being cut into sheets and then formed into cylindrical shapes, which serve as the main body of the drum. These coils provide the necessary strength and durability required for holding and transporting various materials.

- Q: I bought a Remington 870 super mag last fall and wanted to to switch to non-tox steel loads. The gun came with a modified rem choke. I know that not all chokes are qualified to handle steel. It doesn't say anywhere on the choke no steel I was just wondering if anyone out there knew for sure that those chokes that the guns come with won't get damaged be steel.

- All Modified chokes will shoot steel with no problems. It is only when you get more restrictive, full, xfull, and on that you start to run into problems while shooting steel. There are manufacturers out there that make full chokes that can use steel. Carolson is one of them. That is if you want a full choke for steel.

- Q: How does the surface finish of steel coils affect their performance?

- The surface finish of steel coils significantly affects their performance. A smooth and even surface finish enhances the coil's ability to resist corrosion, improves paint adhesion, and enhances the overall appearance of the final product. Additionally, a properly finished surface reduces friction, facilitating better processing and handling during manufacturing. Therefore, the surface finish of steel coils plays a crucial role in determining their durability, functionality, and aesthetic appeal.

- Q: I have a bottle like this* Can u make hot chocolate in it. Can i heat it.I wanna take hot Chocolate to school

- Hot drinks only do well in an insulated thermos. Thermos's were designed for hot drinks. This stainless steel water bottle is not a thermos. You could put hot chocolate or coffee in the water bottle, but you'll burn your hand if you touch it. And, it will cool down very quickly.

- Q: Can steel coils be coated with electrically conductive materials?

- Yes, steel coils can be coated with electrically conductive materials.

- Q: What is the role of steel coils in the production of conveyors?

- Steel coils are used in the production of conveyors as they serve as the main structural component for supporting and guiding the conveyor belt. These coils are typically formed into a cylindrical shape and act as a sturdy foundation for the belt to rest on. Additionally, the strength and durability of steel coils ensure that the conveyor can withstand heavy loads and constant movement, making them essential for efficient and reliable conveyor systems.

- Q: what is the porpose of preheating mild steel prior to welding

- ok dont listen to bob the builder down there, u preheat thicker steels to draw moisture out of them. take a propane torch to something exposed to just atmospheric air around 3 inches thick and the water will literally pour out of it. do u want that in ur weld? no. so u preheat to draw any moisture or contaminates out of the base metal. good luck.

Send your message to us

Prepainted Galvanized Rolled steel DX51D in CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords