Pre-Painted Coated Galvanized Steel Coils/PPGI/Pre-Painted Galvanized Steel Roofing Sheet PPGI

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Specifications;

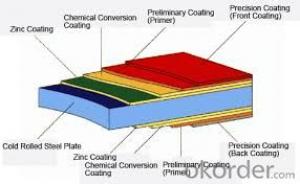

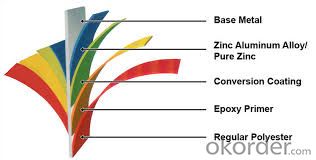

1. Aluzinc coating mass: 30g-275g/sqm

2. Coil weight: 4-6 tons per coil

3. Edge treatment: Mill edge or cut edge.

4. Technical treatment: Bright annealed, flatting, cold harden.

5. Surface treatment: Annealed, bright finish, dull/bright finish, slit edge.

6. Spangle: Normal/small/big/zero spangle.

7. Delivery terms: FOB / C&R / CIF

8. Supply Ability: 30000MT/month

9. Application: The construction industry: The roof structure, keel, grill, Clapboard, ceilings, fire shutter doors, etc; The light industry, the Automobile, agriculture, animal husbandry, fishery, casing of household Electronic application, civilian smoke stack, etc.

10. Delivery time: Within 30 days after the receipt of L/C or Signed the contract or according to customer's requirement.

Special design available according to requirement; Anti-corrosion And high-temperature resistant with black painting; All the production process Are made under the ISO9001: 2000 strictly

Second Glance of Photo

Galvanzied steel coil( GI, CRC)

Color coated steel coil(PPGI)

Package: Sea worthy Export Packing Standard export and seaworthy packing. (waterproof paper and metal sheet protection with fluted rings at inner and outer edges, 4 eye bands and 4 circumferential bands fasten the coil)

FAQ

1. Do you have QC team?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.for quality inspection every day.

- Q: What are the different methods of punching steel coils?

- There are several methods of punching steel coils, including mechanical punching, hydraulic punching, and laser punching. Mechanical punching involves the use of a mechanical press with a punch and die set to create holes or shapes in the steel coil. Hydraulic punching utilizes hydraulic force to drive a punch through the coil, providing high precision and speed. Laser punching, on the other hand, uses a laser beam to cut or form holes in the steel coil, offering great flexibility and accuracy. Each method has its own advantages and suitability depending on the specific requirements of the application.

- Q: Steel used to be made in the #92;Bessemer Converter, write about how steel making processes today produce better quality steel????

- Steel making today is a faster process as use Blast furnace which Coke Limestone Iron ore are fed into the top of the furnace. after these are fed in a exothermic happens and converts these ores into Iron. Iron is not strong enough to be used in thing this is formally known as pig iron. To convert Iron ore into steel it has to go to a process called the BOS Basic Oxygen Steel-making were oxygen is blown onto the iron ore for about 30 to 45 min and this then turns it into steel as all the impurities are taken out and this floats on top and known as slag and used for things such as road building. Once you have steel this is then pored into ladles and taken to the continuous caster and rolled into slabs, billets and bars and then cut off and rolled into a finished products and then taken to compniaes to be made into thins you see made out off metal such as skyscrapers. Hope this helps :o)

- Q: I don't know why but I'm having a VERY difficult time finding the melting point of 1008 steel.

- 1. okorder 2. Input (melting point 1008 steel) as the search string 3. Check the links; the third one showed the answer in an MSDS

- Q: I have a set of Ben Hogan Apex Plus Forged Irons, how can i figure out if the shafts are steel or graphite?

- Hold one club in each hand and hit them together like swords fighting, putting the impact point about midway down each shaft, and listen to the sound. If it's more of a clank sound, it's steel, and more of a click sound, it's graphite.

- Q: Or is it a coating that is applied? If so what types of steel? Or what types of coatings?

- No, usually they are just coated or galvanized. To make a steel that is truly more corrosion resistant raises it's cost quite markedly, where as coatings are pretty cheap. Almost all structural steel is just A36 mild steel (like 0.1% carbon, 0.05% Mn, and not much else). There are higher grades of structural steel, and bridges are made with truly more corrosion resistant carbon steels, but for a house it's just not the case.

- Q: What are the different methods of steel coil surface cleaning?

- There are several methods of steel coil surface cleaning, including mechanical cleaning, chemical cleaning, and high-pressure water cleaning. Mechanical cleaning involves using abrasive materials or brushes to physically remove dirt, rust, and other contaminants from the surface. Chemical cleaning uses various chemicals or solvents to dissolve or loosen the contaminants, making them easier to remove. High-pressure water cleaning involves spraying water at a high pressure to dislodge and wash away the dirt and debris. These methods can be used individually or in combination, depending on the level of cleanliness required and the specific condition of the steel coil.

- Q: I just want to know why is cold steel katana a very good sword?? How can you tell if a cold steel katana is good or not

- Save your money and by a wooden boken. Train with a well balanced wooden one. It is how the great Japanese master started their training. Steel swords are good for display. and perhaps if you become relay good and want to feel the heft and practice cutting straw men and bamboo stalks than invest some money in the real deal for a few hundred $$ at the least.

- Q: Can steel coils be coated with electrically conductive materials?

- Yes, steel coils can be coated with electrically conductive materials.

- Q: earlier name of jsw steel ltd. may be jindal iron steel ltd.

- JSW Steel Ltd - Profile Office Address 5 A, Jindal Mansion, Dr A G Deshmukh Marg, Mumbai Maharastra 400026 Phone 022-23513000 Business Summary JSW Steel Limited Formerly known as Jindal Vijayanagar Steel Limited. The Company's principal activity is to manufacture hot rolled steel coils in India using the revolutionary Corex technology. In addition, the Company also manufactures steel plates and sheets. It manufactures steel using oxygen based iron and steel through continuous casting and hot rolling. Executive Team Executive Name Designation Savitri Devi Jindal Sajjan Jindal Dr. B N Singh Chairperson Additional Director Vice Chairman Managing Director Joint Managing Director

- Q: What are the different types of steel coil packaging methods?

- There are several different types of steel coil packaging methods, including but not limited to: strapping, wrapping, banding, shrink-wrapping, palletizing, and using steel coil covers or caps. Each method serves a specific purpose and provides varying levels of protection and stability during transportation and storage.

Send your message to us

Pre-Painted Coated Galvanized Steel Coils/PPGI/Pre-Painted Galvanized Steel Roofing Sheet PPGI

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords