Galvanized/Aluzinc Steel Coil/Sheet with Best Quality in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

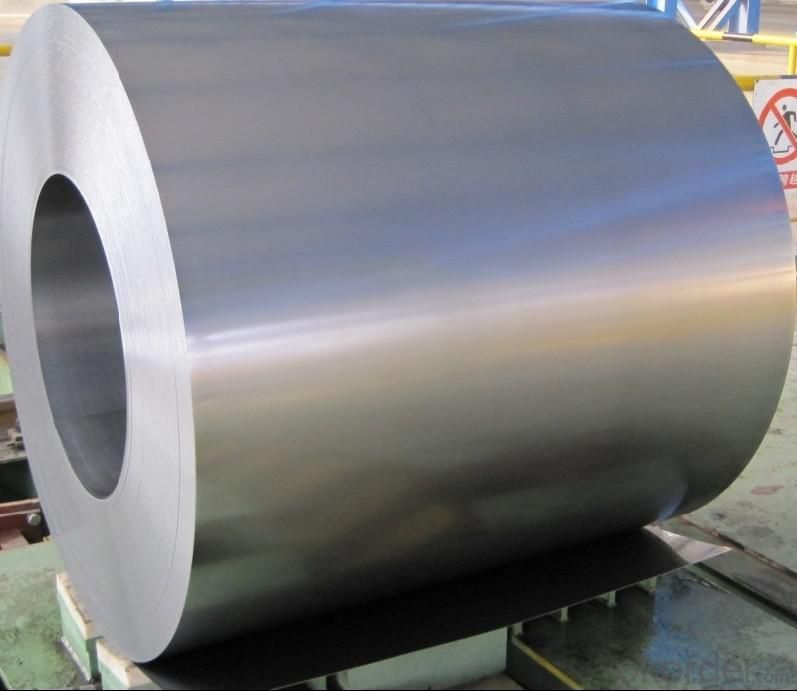

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

| Processability | Yield strength | Elongation % | Elongation % | 180°cold-bending |

| Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

| Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

| Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

| Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

| EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: Consider a steel rod of diameter 4.5 mm and length 3.3 m. If a compressive force of 4900 N is applied to each end, what is the change in the length of the rod?

- You need to calculate the stress on the rod and compare this with the mechanical properties of the steel. It would help if you were given more info. You will need to know something about the steel such as the yeild stress and E, the modulus of elasticity. The value of E is about the same for a wide range of steels. So long as the applied stress is below the yield stress, the strain is all elastic and is calculated from E. The real answer is that you can not answer this question since you do not know what the temperature is. Given the applied load, the change in length will be much different at room temperature than at 1500C.

- Q: were iron age weapons made of steel?

- No, the iron age was just iron. It was smelted down in open fires where temperatures can vary. There was a problem of not always being able to cook out all the impurities from the ore, which led to inconsistent strengths in finished products. People first discovered the properties and advantages of steel when charcoal (carbon) was added to smelted iron. I don't know when the first steel was made. But it must have been a more expensive process because it didn't appear in household products until around 1800. But I'm not sure on that.

- Q: How are steel coils used in the HVAC industry?

- Steel coils are commonly used in the HVAC industry as a key component in air conditioning and heating systems. They are used to transfer heat energy, allowing the system to cool or heat the air efficiently. The steel coils act as heat exchangers, absorbing heat from the air and releasing it into the environment or vice versa. This process helps regulate the temperature and improve the overall performance of HVAC systems.

- Q: I should have known, but magnets don't stick to stainless steel, so now I'm at a loss, I can't display my photos on the fridge. any ideas?

- An Italian theme would be great for that or just sleek clean lines with the colors stainless steal, red, and accented with black. I like that personally. But it is up to you and what you like and don't like. You could also go an Asian theme. That would be pretty. Asian stuff seems to lean toward reds, greens, and neutrals.

- Q: How are steel coils used in the production of industrial storage tanks?

- Industrial storage tanks commonly utilize steel coils due to their superior strength and durability. These coils are typically crafted from high-quality steel that is rolled into a coil shape, enabling convenient transportation and handling. During the production process, steel coils are initially uncoiled and flattened to create steel sheets. These sheets are then cut and formed into the desired shape and size for the storage tank. The steel sheets are joined together through welding or bolting to construct the tank's body, which is designed to endure high pressure and heavy loads. The utilization of steel coils in the production of industrial storage tanks offers numerous benefits. Firstly, the strength and durability of steel ensure that the tanks can withstand harsh conditions and resist corrosion. This is particularly vital for storage tanks containing corrosive substances or exposed to severe environments. Moreover, the flexibility of steel coils permits customization of the tank's design and size. This is especially advantageous in industries with varying storage requirements, like the oil and gas sector. Steel coils can be effortlessly cut and molded into diverse shapes and sizes, facilitating the creation of storage tanks tailored to specific storage needs. Furthermore, steel coils are easily transportable and storable, making them a cost-effective choice for industrial storage tank production. The coils can be efficiently transported to the manufacturing facility, reducing transportation costs and logistical complexities. In conclusion, steel coils play a crucial role in the production of industrial storage tanks by providing strength, durability, and customization options. Their usage guarantees the safe storage and protection of various substances, rendering them indispensable in a wide range of industries.

- Q: Can steel coils be welded?

- Yes, steel coils can be welded. Welding is a widely used process for joining metal components, including steel coils.

- Q: How are steel coils used in the production of household goods?

- Steel coils are an essential component in the production of various household goods. These coils are typically made from high-quality steel and are manufactured to specific dimensions and thicknesses to meet the requirements of different products. One of the primary uses of steel coils in household goods production is in the manufacturing of appliances such as refrigerators, washing machines, and dishwashers. The coils are used to create the body and framework of these appliances, providing strength, durability, and stability. Additionally, steel coils are often used in the production of smaller household appliances like toasters, blenders, and coffee makers. Furthermore, steel coils are also used in the production of furniture, particularly in the manufacturing of metal frames for chairs, tables, and cabinets. These coils provide the necessary support and structural integrity to the furniture, ensuring long-lasting durability. Another significant application of steel coils in household goods production is in the production of shelving units and storage solutions. Steel coils can be shaped and formed to create sturdy shelves and racks that can hold heavy items and withstand regular use. These shelves are commonly used in kitchens, garages, and storage rooms to organize and store various household items. In summary, steel coils play a crucial role in the production of household goods. They are used to create the framework, structure, and support for appliances, furniture, and storage solutions. Their strength, durability, and versatility make them an ideal material for manufacturing a wide range of household products that are designed to withstand everyday use.

- Q: I want to buy a machete made of 1055 carbon steel, and want to know if this steel is durable for repeated use, or even combat use.

- 1055 Carbon Steel

- Q: I was wondering because i just watched an episode of build it bigger on the discovery channel about the uss George bush, and when they were discribing it they said it was 500 tons of steel and 47,000 tons of aluminum. this kinda struck me as odd because i thought that it was mostly made of steel. and i would think that even if it was mostly aluminum, that the hull would be steel. and i think the hull would weigh more than 500 tons.

- STEEL okorder /

- Q: I read that contrary to popular belief, today's folded steel swords are only made that way for tradition and cosmetics. In the past steel was very impure and therefore had to be folded in order to make a good sword. Today's steel manufacturing provides very pure steel and so folding the metal only makes it look nicer, but does nothing to improve the function of the blade.What do you think of this?

- This Site Might Help You. RE: Does folding modern steel do anything to enhance a sword? I read that contrary to popular belief, today's folded steel swords are only made that way for tradition and cosmetics. In the past steel was very impure and therefore had to be folded in order to make a good sword. Today's steel manufacturing provides very pure steel and so folding the...

Send your message to us

Galvanized/Aluzinc Steel Coil/Sheet with Best Quality in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords