Chinese Pre-Painted Galvanized/Aluzinc Steel Coil with Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Chinese Pre-Painted Galvanized/Aluzinc Steel Coil with Best Quality

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

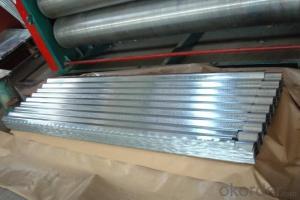

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: What is the shear modulus of steel and silver? Please help! and state where you got it from...what site did you used? Thanks.

- There are more than 10,000 different steel alloys that have been specified and used for different purposes. They cover a huge range of mechanical properties. For silver, are you talking about pure silver, or a silver alloy with a additives to improve its mechanical properties? Typical values for mild steel at room temperature are E = 210 GPa, G = 80 GPa (source: 30 years working as a mech. engineer) Wikipedia gives E = 80GPa, G = 30GPa for pure silver (temperature not specified). Silver alloys may be very different from those values. The properties will also depend on the metal forming process (e.g. drawn wire, annealed, etc). NB some alloys with silver in their common name contain no silver at all.

- Q: I need the measurements of the height and hypotenuse of the first drop in the Steel Dragon 2000. I couldn't find it anywhere. It would be great if you could also show me the website where you got your answer. Thanks! =]*The hypotenuse is the length of the drop.*

- Steel Dragon 2000 is a roller coaster at Nagashima Spa Land Amusement Park in Mie Prefecture, Japan. Built by Morgan Manufacturing, this gigacoaster opened, appropriately, in 2000 - The Year of the Dragon in the Far East. It debuted only months after Millennium Force and surpassed the Cedar Point coaster as the world's tallest complete-circuit coaster. It also set a record for longest track length - 8133 feet, 2 inches (2479 m), which it currently holds. Coaster Facts * Steel Dragon 2000 is the tallest coaster to utilize a traditional chain lift. Because of the length of the lift hill, two chains are used - one for the bottom half and one for the top half. A single chain would have been excessively long and heavy, at least twice the weight of one of the trains. As a result, two trains can safely occupy the lift simultaneously. * The building of Steel Dragon 2000 required far more steel than other coasters for earthquake protection. This put the cost of the coaster at over $50,000,000. * On August 23, 2003, Steel Dragon 2000 was involved in an accident during a run in which one of its trains lost a wheel. The coaster did not operate during the 2004 and 2005 park seasons. It reopened September 3, 2006.

- Q: What is the average shelf life of a steel coil?

- The average shelf life of a steel coil can vary depending on various factors such as the type of steel, storage conditions, and maintenance practices. However, on average, a steel coil can have a shelf life of around 6 to 12 months if stored properly in a controlled environment with suitable temperature, humidity, and protection from corrosion. Regular inspection and maintenance can extend the shelf life of a steel coil further.

- Q: I have my grandpa's navy knife from ww2, a mk2 combat knife i think, and i was wondering what type of steel it is made of. I'm guessing it's a high carbon steel, i'd just like to know exactly what grade.

- 1095 Steel - Easy to sharpen, plain carbon steel used in knife making. Proven to be one of the most popular steels used in KA-BAR knives. Right from the OEM site. Worked for a company that started in 1859 as a safe manufacturer. The steel recipes have not changed much from WWII (when Elliot Ness was running the company) to now. Doubt the KA-BAR recipes has changed either.

- Q: not iron, steel

- steel was first used in the 1800s in buildings.

- Q: What are the different methods of coil slitting for precision cuts?

- Coil slitting is a process used to cut large coils of material, such as steel, into narrower strips with precise dimensions. There are several methods of coil slitting for achieving precision cuts, each offering unique advantages and suitable for different applications. 1. Rotary Shear Slitting: This is the most common method used for coil slitting. It involves passing the coil through rotating circular knives that create two or more strips by shearing the material. The blades can be set at different distances apart to achieve the desired width of the strips. Rotary shear slitting offers high precision and is capable of producing smooth, burr-free edges. 2. Drag Knife Slitting: In this method, a knife with a drag or tangential orientation is used to cut the coil. The knife moves in a controlled path, following the contour of the material and producing accurate cuts. Drag knife slitting is suitable for materials with irregular shapes and is often used in the textile industry for cutting fabrics. 3. Scissor Slitting: Scissor slitting involves the use of two blades that move against each other in a scissor-like motion to cut the coil. This method is commonly used for thinner materials and provides excellent control over the cutting process. Scissor slitting is ideal for achieving precise cuts in materials that are prone to deformation or wrinkling. 4. Razor Slitting: Razor slitting utilizes a single razor blade or multiple razor blades in a holder to cut the coil. The blade(s) are positioned perpendicular to the material and slice through it. This method is particularly effective for cutting stretchy or delicate materials, such as plastic films or paper, as it minimizes the risk of tearing or deforming the material. 5. Crush Cutting: Crush cutting involves using a hardened steel roller or an anvil against a softer material, such as foam or rubber, to cut the coil. The pressure applied causes the material to deform and split along the desired cutting line. Crush cutting is suitable for materials that are difficult to cut with sharp blades and can produce precise, clean cuts. Overall, the choice of coil slitting method depends on the material being cut, the desired precision, and other requirements of the specific application. Each method offers its own benefits and can be tailored to meet specific cutting needs, ensuring accurate and efficient coil slitting processes.

- Q: How are steel coils manufactured?

- Steel coils are manufactured through a multi-step process that involves heating and shaping steel slabs, followed by passing them through a series of rolling mills to reduce their thickness and increase their length. The coils are then cooled, inspected for quality, and finally, wrapped and ready for shipping.

- Q: How are steel coils inspected for camber?

- Steel coils are inspected for camber by using a straight edge or a camber gauge, which is placed on top of the coil to measure any deviation from straightness. The operator checks the distance between the straight edge and the coil at various points along its length to determine the amount of camber present.

- Q: How are steel coils used in the manufacturing of bridges?

- Steel coils are used in the manufacturing of bridges as they serve as the primary material for constructing the bridge's structural components, such as beams and girders. These coils are processed through various stages, including cutting, shaping, and welding, to create the necessary structural elements that provide strength and support to the bridge. The durability and load-bearing capacity of steel coils make them ideal for withstanding the heavy loads and stresses experienced by bridges, ensuring their stability and longevity.

- Q: What are the different types of steel coil handling devices?

- There are several types of steel coil handling devices, including coil lifters, coil grabs, coil tongs, coil hooks, and coil C-hooks. These devices are designed to safely and efficiently handle steel coils of various sizes and weights, allowing for easy transportation and storage in industrial settings.

Send your message to us

Chinese Pre-Painted Galvanized/Aluzinc Steel Coil with Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords