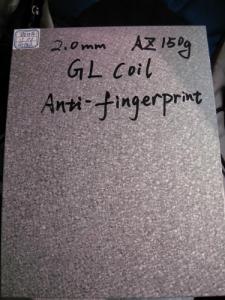

Galvalume Steel Sheet & Coil ASTM A792 AZ150

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Seaworthy Packing |

| Delivery Detail: | 25days |

Specifications

Galvalume steel coils

Min Yield Strength of 550MPA

Min/Regular Spangle

Zinc coating:60-600g/m2

Hot Dipped 55% Aluminum Zinc Alloy Coated Steel by the Hot-Dip Process

Hot Dip Galvalume steel coil EN 10327 JIS G3321, ASTM A792M 55% AL-ZN coated

Description:

The hot dip galvalume steel is a kind of coated steel. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. It enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Comparison

Item | GI | GF(Zn-5%Al) | GALVA-LUME(55%Al-45%Zn) | Al |

Service Life | Fair | Fair | Good | Good |

Electrochemical Protection | Good | Good | Good | N/A |

Welding Performance | Good | Fair | Poor | Poor |

Application with Wet Concrete | Good | Poor | Very Poor | Very Poor |

Thermal Resistance | Poor | Poor | Good | Excellent |

Specifications:

Standard | EN 10327 | DX51D+AZ, DX52D+AZ, DX53D+AZ, |

EN 10326 | SS250GD+AZ, SS350GD+AZ | |

JIS G3321 | SGLCC, SGLCD, SGLCDD, SGLC 400 | |

ASTM A792M | CS type C, CS type B, DS, SS255, SS345 | |

Base Metal | Cold rolled steel coils SPCC, SPCD, SPCE, DC01, DC03, DC04, CS, DS, DDS, Q195, Q250, Q350 | |

Thickness | 0.22mm-2.0mm | |

Width | 700mm-1300mm | |

Coil ID | 508mm, 610mm | |

Zinc coating | 60g/m2-180g/m2 | |

Surface treating | chromium free passivation, chromium passivation, fingerprint resistant, oiled | |

Spangle types | regular spangle | |

Applications:

Architecture | Roofs and outside walls of civilian and industrial buildings, garage doors, fencings and window blinds |

Appliances Industry

| Outer clad sheets for washing machine, refrigerator, television, air conditioner and ventilation system, explosion-proof strip, solar water heater and appliance parts |

Auto Industry

| Muffler, heat shields of exhaust pipe and catalytic converter, auto parts & accessories under the frame, signboard in highway. |

Industrial Instruments

| Electric control cabinet, industrial refrigeration equipment, automatic vending machine |

- Q: How are steel coils used in the packaging industry?

- Steel coils are used in the packaging industry primarily for the production of metal strapping and seals. These coils are unwound and processed to create strong and durable strapping materials that are used to secure and bundle various types of packaging, such as boxes, crates, and pallets. The steel coils provide excellent tensile strength and resistance to breakage, making them ideal for ensuring the safe transportation and storage of goods.

- Q: I got my dog those nice looking stainless steel water and food bowls (looks great next to my kitchen appliances...haha). The thing is my dog will drink from the toilet or a plastic bowl but not out of his bowl...I was wondering if those stainless steel bowls change the taste of food and water?

- Well, I know the water at this restaurants where they use metal pitchers taste a bit off to me. There's nothing wrong with the water, but I think the metal pitcher throws off the flavor. Could be the same with the metal bowl and the dog. Plastic is only a problem at hiding bacteria if it gets scratched up badly (which isn't as likely to happen with water as long as the dog doesn't chew it. You can also put the plastic crock bowls on the top shelf of a dishwasher for cleaning as the heat kills most germs.

- Q: - I'm considering doing my physics coursework on the uses of Mild Steel in skyscrapers and construction, would this be right? Some sources tell me mild steel is too weak, others say it is fine

- Mild steel doesn't really mean anything, technically. In today's world all steel is mild steel unless it's high carbon or alloy, which are mostly tool steels. You'll need to study steel much deeper than that to accomplish any real physics work relating to steel.

- Q: What are the different methods of tempering steel coils?

- There are several different methods of tempering steel coils, each with its own advantages and disadvantages. Some of the most common methods include: 1. Air cooling: This is the simplest and most common method of tempering steel coils. The coils are heated to a specific temperature and then allowed to cool naturally in ambient air. This method is relatively quick and cost-effective, but it can result in uneven cooling and may not provide as precise control over the final properties of the steel. 2. Water quenching: In this method, the steel coils are heated and then rapidly cooled by immersing them in a bath of water. Water quenching provides a more rapid and controlled cooling rate than air cooling, resulting in greater hardness and strength. However, it can also lead to increased distortion and the formation of internal stresses in the steel. 3. Oil quenching: Similar to water quenching, oil quenching involves immersing the steel coils in a bath of oil to rapidly cool them. Oil quenching provides a slower and more uniform cooling rate compared to water quenching, resulting in reduced distortion and internal stresses. However, it also produces slightly lower hardness and strength compared to water quenching. 4. Salt bath quenching: This method involves immersing the steel coils in a heated bath of molten salt to rapidly cool them. Salt bath quenching provides an even and controlled cooling rate, resulting in improved hardness and strength compared to air or water quenching. However, it requires specialized equipment and may not be suitable for all types of steel. 5. Induction hardening: In this method, the steel coils are heated using an induction heating process and then rapidly cooled using either air, water, or oil quenching. Induction hardening allows for precise control over the heating and cooling process, resulting in specific hardness and strength properties in desired areas of the steel. However, it requires specialized equipment and is typically used for specific applications or parts of the steel coils. Overall, the choice of tempering method depends on various factors such as the desired properties of the steel coils, the type of steel being used, and the specific requirements of the end application.

- Q: How are steel coils inspected for paint adhesion using adhesion testers?

- Steel coils are inspected for paint adhesion using adhesion testers in a systematic and rigorous manner. Adhesion testers are devices specifically designed to evaluate the bond strength between the paint and the underlying steel surface. The inspection process begins by selecting representative samples from the steel coils. These samples are usually cut into smaller sections, ensuring that they are free from any defects or surface irregularities that could affect the adhesion test results. Once the samples are prepared, the adhesion testers are employed to measure the force required to detach the paint coating from the steel surface. The most commonly used adhesion tester is the cross-cut adhesion tester. This device consists of a set of blades arranged in a grid pattern. The blades are used to create a series of cuts through the paint coating down to the steel surface, forming a grid of squares or rectangles. After the cuts are made, a specialized tape is applied to the grid area and pressed firmly onto the surface. The tape is then rapidly pulled off at a 90-degree angle to the surface. The force required to remove the paint coating from the steel is measured and recorded. The results of the adhesion test are evaluated based on predetermined standards or specifications. These standards typically define the minimum acceptable adhesion strength for the specific application or industry. If the measured adhesion strength falls below the specified threshold, it indicates poor paint adhesion, which could lead to issues such as paint delamination or corrosion. In addition to the cross-cut adhesion tester, other adhesion testing methods may also be used, such as the pull-off adhesion tester, where a hydraulic or mechanical device applies a tensile force to a small circular or dolly-shaped test area. The force required to pull off the dolly is measured and used to assess the paint adhesion. Overall, the use of adhesion testers ensures that steel coils are thoroughly inspected for paint adhesion. This helps to identify any potential adhesion issues early on, allowing for appropriate remedial measures to be taken to ensure the longevity and performance of the paint coating.

- Q: How does the surface finish of steel coils affect their performance?

- The surface finish of steel coils greatly affects their performance. A smooth and uniform surface finish enhances the coil's corrosion resistance, durability, and ability to resist wear and tear. It also improves the coil's ability to form and join with other materials, making it easier to work with during manufacturing processes. On the other hand, a rough or uneven surface finish can lead to decreased performance, as it can negatively impact the coil's ability to resist corrosion, reduce its overall strength, and potentially cause issues during processing and handling. Therefore, ensuring a proper surface finish is crucial in optimizing the performance and lifespan of steel coils.

- Q: What are the applications of stainless steel coils?

- Stainless steel coils have a wide range of applications across various industries due to their unique properties and characteristics. Some of the key applications of stainless steel coils include: 1. Manufacturing industry: Stainless steel coils are extensively used in the manufacturing sector for the production of various products such as automotive parts, kitchen appliances, machinery components, and construction materials. The high corrosion resistance and durability of stainless steel make it an ideal choice for these applications. 2. Construction industry: Stainless steel coils are widely used in the construction industry for applications such as roofing, cladding, structural supports, and reinforcement. The strength, resistance to harsh weather conditions, and aesthetic appeal of stainless steel make it a popular choice in architectural designs. 3. Food processing industry: Stainless steel coils are commonly utilized in the food processing industry for equipment such as food storage tanks, conveyors, and processing machinery. Stainless steel's hygienic properties, resistance to corrosion, and ease of cleaning make it suitable for maintaining the purity and safety of food products. 4. Chemical industry: Stainless steel coils find extensive usage in the chemical industry due to their excellent resistance to corrosion from chemicals and harsh environments. They are used in the production of storage tanks, pipelines, and reactors that handle various chemicals and corrosive substances. 5. Energy industry: Stainless steel coils are widely employed in the energy sector for applications such as power generation, oil and gas exploration, and renewable energy systems. They are used in heat exchangers, turbine components, pipelines, and offshore structures due to their high resistance to corrosion, strength, and longevity. 6. Medical and pharmaceutical industry: Stainless steel coils are commonly used in medical and pharmaceutical applications due to their biocompatibility and resistance to corrosion. They are used in the production of surgical instruments, medical implants, and medical equipment that require sterilization and durability. 7. Automotive industry: Stainless steel coils are utilized in the automotive sector for various components like exhaust systems, fuel tanks, catalytic converters, and structural parts. Stainless steel's high heat resistance, strength, and resistance to corrosion and oxidation make it suitable for these applications. These are just a few examples of the wide range of applications of stainless steel coils. Their versatility, durability, and resistance to corrosion make them indispensable in numerous industries where reliability and longevity are crucial factors.

- Q: How are steel coils used in the construction of buildings?

- Steel coils are used in the construction of buildings for various purposes, primarily for structural support. These coils are typically used to create steel frames, beams, and columns that provide strength and stability to the structure. Additionally, steel coils are also used in the production of roofing materials, wall cladding, and reinforcement bars, which further enhance the durability and safety of the building.

- Q: Are Steel Building Kits really helpful while erecting a steel building?

- Of course yes! Steel building kit is design specific corresponding to the type of steel building required to be constructed or erected. The steel building kit consists of all the necessities needed by the purchaser or the investor. As steel buildings are prefabricated or pre-engineered they are manufactured in factories in various sections and parts which are to be brought to the construction site to be assembled. So in any case they are beneficial :)

- Q: How are steel coils used in the production of storage tanks?

- Steel coils are typically used as the raw material in the production of storage tanks. These coils are formed into sheets and then shaped and welded to create the tank's body. The strength and durability of steel make it an ideal choice for storing various substances, including liquids and gases, ensuring the safety and longevity of the storage tanks.

Send your message to us

Galvalume Steel Sheet & Coil ASTM A792 AZ150

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords