Prime Hot Rolled Steel Sheets in Coils Steel Coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Our main procucts are steel billet, steel plates, steel coils and wire rod. Moreover,our hot rolled coil and ship building plate are certificated respectively by CARES, CE from Eurpoean Union and CCS authentication from nine nations. Our products are widely used in various areas,such as millitary, aerospace, transportation, equipment manufacturing, shippin, petroleum pipe line, buildings etc.

| Production Name | Hot Rolled Steel Coils |

| Loading Port | Any Port in China |

| Thickness | 1.8mm-16mm |

| Width | 1000mm-1600mm |

| Coil Weight | 28 mt max |

| Material Grade | SS400\Q235\SAE1006\SAE1008 |

| Technique | Hot Rolled |

| Standard | GB \JIS\ASTM |

| Test | With Hydraulic Testing, Eddy Current , Infrared Test |

| Surface | 1) Bared |

| 2) Oiled | |

| Package | Standard Export Packing,Or at Customer’s Requirement |

| Sample | Common products, we can provide freely, for special production,we can depends on negotiation. |

| Payment | 100% L/C at sight, 30% T/T in advance |

| Delivery time | Within 10-25 days, according to quantity, asap save customer’s time |

| Certificate | ISO |

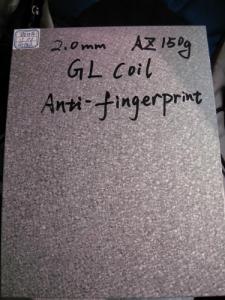

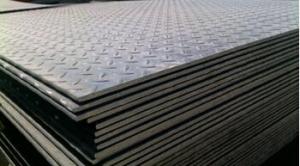

Product Images:

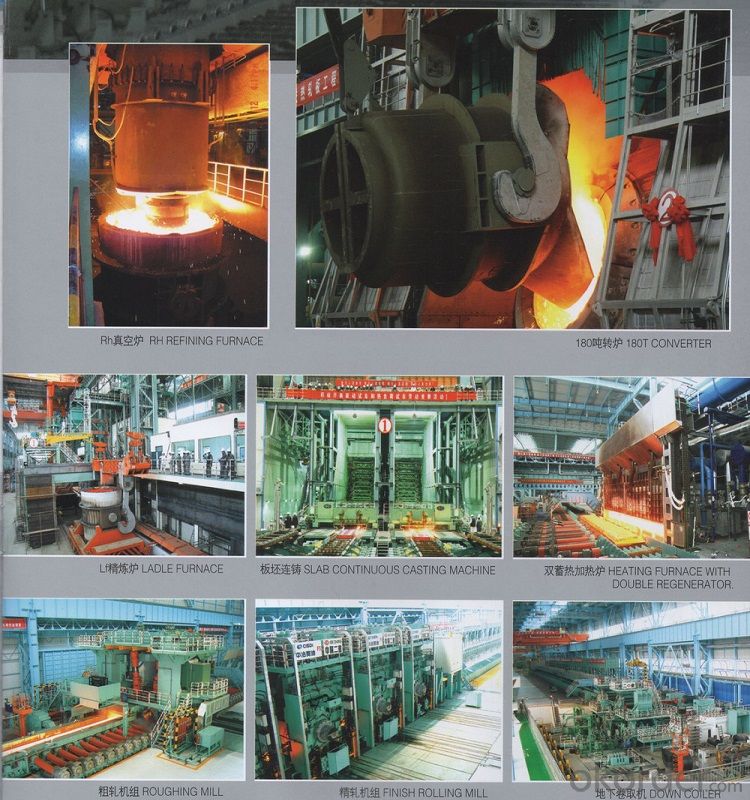

Product Process:

Our Service

Delivery time | 20-35days after receiving the payment of 30% deposit. |

Payment | -Irrevocable L/C at sight. |

-30% T/T in advance and 70% balance against copy of B/L. | |

Packing | -Standard Export Packing |

-According to customer's request. | |

Load port | Tianjin port, Shanghai port, Ningbo port or customer's request |

Feedback | If you have any questions, please feel free to contact us at any time possible. |

We will reply as soon as possible. | |

After Sale | Any questions of the production, please let me know directly by email or phone. |

We can deal with these issues on time, promise give you happy answers. | |

We focused on the after sale. Welcome send any comments to us. |

FAQ

1. Q: Where is your company located? How can I visit there?

A: Our company is located in Beijing, China. Welcome to visit us.

2. Q: Can I get sample and how long will it take?

A:Yes. We can supply sample. And you need to pay for courier.

3. Q: What's the MOQ?

A: Our MOQ is 25mt.

4. Q: What's the delivery time?

A: It will take about 30 days after TT or L/C.

5. Q: What is the payment terms?

A: T/T, L/C at sight

6. Q: How does your factory carry out quality control?

A: We attach great importance to quality control.Every part of our products has its own QC.

7. Q: What certificate do you have?

A: We have SGS, ISO9001 etc. Also we can apply any certificate if you need if the qty is OK.

- Q: Can steel coils be welded together?

- Yes, steel coils can be welded together. Welding is a common technique used to join metals, including steel coils. It involves melting the edges of the coils and fusing them together using a filler material. This process creates a strong and durable bond between the coils, allowing them to be joined and used as a single unit. Welding steel coils together is commonly done in various industries, such as manufacturing, construction, and automotive, to create larger structures or components. However, it is important to ensure proper welding techniques and quality control measures are followed to ensure the integrity and strength of the weld joint.

- Q: i know that steel helmets werent meant to stop bullets, but i was wondering do they have an value whatsoever for stopping bullets, or is that just yet another thing that hollywood made up(like the omaha beach scene in saving private rian)

- richard S is right. They were designed to deflect shrapnel more than anything else, but I have seen few cases where a round striking at the right angle was deflected enough to safe the soldier. The new Kevlar helmets perform much better, I have seen them stop an AK 47 round (7.62x39MM) and they will stop most military handgun rounds. shoot safe

- Q: How much does a steel coil weigh?

- The weight of a steel coil can vary depending on its size, thickness, and type of steel used. On average, steel coils can weigh anywhere from a few hundred pounds to several tons.

- Q: What is the role of steel coils in the manufacturing of pipes and tubes?

- Steel coils play a critical role in the manufacturing of pipes and tubes. They are the primary raw material used to produce these products. Steel coils are made by processing molten steel through a series of rolling mills, which shape the steel into flat, thin sheets. These sheets are then wound into coils for easy transportation and storage. In the manufacturing process of pipes and tubes, steel coils are unwound, and the flat sheets are passed through a series of machines and processes. The first step is usually to cut the steel sheets into the desired width and length. This is followed by forming the sheets into a cylindrical shape through a process called roll forming or continuous forming. The edges of the sheet are welded together to create a continuous pipe or tube. Steel coils provide several advantages in the manufacturing process. Firstly, they offer consistent and reliable quality. The production of coils ensures uniform thickness and strength throughout the entire length of the sheet, which translates to consistent properties in the final pipes and tubes. This is particularly important for applications that require high structural integrity and reliability. Secondly, steel coils allow for efficient production. The continuous supply of coils ensures a steady flow of raw material, reducing downtime and improving productivity. Coils also enable automated processes, such as roll forming, which can be highly efficient and cost-effective. Furthermore, steel coils offer flexibility in terms of size and dimensions. Coils can be produced in various widths and thicknesses, allowing manufacturers to customize the size and specifications of the pipes and tubes according to their specific requirements. This flexibility enables the production of pipes and tubes for a wide range of applications, from plumbing and construction to oil and gas pipelines. In conclusion, steel coils are the essential raw material in the manufacturing of pipes and tubes. They provide consistent quality, enable efficient production, and offer flexibility in size and dimensions. Without steel coils, the production of pipes and tubes would be significantly more challenging and less efficient.

- Q: How are steel coils welded together?

- Different methods can be employed to weld steel coils together, depending on the specific requirements and the type of steel being used. Electric resistance welding (ERW) is a common method where an electric current is utilized to generate heat in the coils, melting their edges. Pressure is then applied to join them together. ERW is a cost-effective and speedy technique for welding steel coils. Thinner steel coils are often welded using high-frequency induction welding (HFIW). This involves the use of an induction coil to produce an alternating magnetic field, inducing an electric current in the coils. The resistance of the coils to this current generates heat, causing the edges to melt and form a weld. For thicker and heavier steel coils, submerged arc welding (SAW) is commonly employed. This technique utilizes a granular flux and a continuous electrode that is fed into the weld area. The flux melts, creating a protective shield for the weld pool, while the electrode melts to form the weld. SAW is a robust and efficient method for welding steel coils. In addition to these methods, laser welding and gas metal arc welding (GMAW) can also be utilized for welding steel coils. Laser welding offers high precision and speed, while GMAW, also known as MIG welding, utilizes an electric arc between a consumable wire electrode and the steel coils to create a weld. Irrespective of the welding method employed, successful welding of steel coils hinges on proper edge preparation, maintenance of appropriate heat and pressure levels, and the use of correct welding techniques.

- Q: What are the different methods of engraving steel coils?

- There are several different methods of engraving steel coils, each with its own advantages and applications. Some of the most common methods include: 1. Chemical Etching: This is a process that involves applying a chemical solution to the surface of the steel coil, which selectively removes the metal to create the desired design. Chemical etching is highly precise and can produce intricate patterns and fine details. It is commonly used for decorative purposes, such as creating logos or patterns on steel coils. 2. Laser Engraving: Laser engraving uses a high-powered laser beam to remove the top layer of the steel coil, creating a permanent mark. This method offers high precision and allows for the engraving of complex designs, logos, or text. Laser engraving is frequently used for branding purposes or to add identification marks to steel coils. 3. Mechanical Engraving: Mechanical engraving involves the use of a cutting tool or a diamond-tipped stylus to physically remove the metal from the steel coil's surface. This method is known for its durability and versatility, as it can create deep and long-lasting engravings. Mechanical engraving is often used for industrial applications, such as adding serial numbers, part codes, or other identification marks to steel coils. 4. Electrochemical Etching: Electrochemical etching, also known as electrolytic etching, utilizes an electric current to selectively dissolve the metal surface of the steel coil. This technique is commonly used for marking and branding purposes, as it can produce high-quality, permanent engravings. Electrochemical etching is often employed in industries where precision and durability are essential, such as aerospace or automotive manufacturing. 5. Inkjet Printing: While not strictly engraving, inkjet printing is a method that can be used to add patterns or designs onto steel coils. This process involves using specialized inks and a digital printing system to apply the desired design directly onto the surface of the coil. Inkjet printing is versatile, cost-effective, and allows for high-resolution prints, making it suitable for various applications, including decorative or branding purposes. In conclusion, the different methods of engraving steel coils offer a range of options for creating permanent markings, logos, or patterns. The choice of method depends on factors such as the desired level of precision, durability requirements, and the specific application for the steel coil.

- Q: What are the common methods of protecting steel coils from corrosion during storage?

- To safeguard steel coils from corrosion during storage, there are multiple commonly employed techniques. These methods aim to shield the steel coils from moisture and other environmental factors that could trigger corrosion. 1. VCI (Volatile Corrosion Inhibitor) Packaging: VCI packaging is extensively utilized for steel coil protection. It incorporates VCI materials into the packaging, such as plastic bags or films. These materials emit a vapor that forms a protective layer on the surface of the steel coils, effectively preventing the intrusion of moisture and corrosive agents. 2. Oil Coating: Another widely adopted approach involves applying a thin layer of oil onto the steel coil surface. This oil acts as a barrier, obstructing the contact between the steel and moisture or oxygen. It proves particularly effective for long-term storage or transportation situations. 3. Desiccants: Silica gel packets or similar desiccants can be placed inside the packaging to absorb any trapped moisture. By reducing humidity levels within the packaging, the risk of corrosion is minimized. This method is often combined with VCI packaging or oil coating. 4. Proper Ventilation: Adequate ventilation is crucial to prevent moisture buildup around the steel coils during storage. By facilitating the free circulation of air, humidity levels are reduced, and the formation of condensation, which can lead to corrosion, is prevented. 5. Controlled Environment: Storing steel coils in a controlled environment is an effective corrosion prevention measure. This entails maintaining constant temperature and humidity levels that are unfavorable for corrosion. Temperature and humidity control can be achieved using air conditioning or dehumidification systems. It should be noted that the choice of specific protection methods or combinations thereof depends on various factors, including storage duration, environmental conditions, and specific steel coil requirements. Regular inspections and maintenance are also vital to ensure ongoing corrosion protection.

- Q: What are the different methods of coil slitting for steel coils?

- There exists a variety of techniques for coil slitting steel coils, each serving a specific purpose and employed in various industries. Here are several commonly used methods: 1. The most widely employed technique for coil slitting is rotary shear slitting. It entails the utilization of rotating knives to divide the steel coil into smaller strips. Renowned for its speed and precision, rotary shear slitting is ideal for large-scale production. 2. Loop slitting involves feeding the steel coil through a loop control system that maintains constant tension. Subsequently, a rotating knife is used to cut the coil into strips. Loop slitting is often utilized for thinner gauge materials due to its ability to produce clean, burr-free edges. 3. Oscillating shear slitting employs oscillating knives to cut the steel coil. These knives move back and forth rapidly, creating a shearing effect that facilitates cutting through the coil. This technique is commonly used for thicker gauge materials and can handle higher tensile strengths. 4. Crush cut slitting involves pressing a circular blade against the steel coil to cut it. The blade crushes the material, resulting in a cut. This method is frequently used for softer materials or when edge quality is not of utmost importance. 5. Slit edge rolling is a technique that involves rolling the edges of the steel coil after it has been slit. This process smooths out the edges and enhances the appearance of the strips. Slit edge rolling is often employed in applications that require a high-quality finish. 6. Laser slitting is a relatively new method that utilizes a laser beam to cut through the steel coil. This technique offers precision and can handle a wide range of thicknesses. Laser slitting is commonly used in high-precision applications where edge quality is crucial. These represent just a few of the various coil slitting methods for steel coils. The selection of a method depends on factors such as material thickness and tensile strength, desired edge quality, and the intended application of the slit strips.

- Q: What are the common defects in steel coil finishes?

- There are several common defects that can occur in steel coil finishes. These defects can impact the appearance and functionality of the steel and may need to be addressed before the coil can be used or sold. 1. Coil breaks: Coil breaks are a common defect where the steel strip breaks during winding or unwinding. This defect can result in a discontinuity in the surface of the coil and can lead to further damage if not addressed. 2. Edge wave: Edge wave refers to a distortion or waviness at the edges of the steel coil. This defect can occur during the rolling or cooling process and can affect the flatness and uniformity of the coil. 3. Corrosion: Corrosion can occur on the surface of steel coils if they are not properly protected or stored. This can lead to rust and degradation of the steel, impacting its strength and appearance. 4. Streaks and stains: Streaks and stains can occur on the surface of steel coils due to improper cleaning or contamination during the production process. These defects can affect the aesthetic appearance of the steel and may need to be addressed before the coil can be used. 5. Scratches and dents: Scratches and dents can occur on the surface of steel coils during handling, transportation, or storage. These defects can impact the flatness and surface quality of the steel and may require repairs or adjustments. 6. Coating defects: If the steel coil has a coating or paint applied to it, several defects can occur. These include blistering, peeling, or uneven application of the coating, which can affect the durability and appearance of the steel. It is important to note that these defects can vary in severity and may require different methods of repair or mitigation. Regular inspections and quality control measures can help identify and address these defects before they become more significant issues.

- Q: What are the different methods of coil slitting for precision cuts?

- Coil slitting, a process utilized for cutting large coils of material into narrower strips, is achieved through various methods that offer distinct advantages and suitability for different applications. 1. Rotary Shear Slitting, the most commonly used method, employs rotating circular knives to shear the material and create multiple strips. The distance between the blades can be adjusted to achieve the desired width. This method guarantees high precision with smooth and burr-free edges. 2. Drag Knife Slitting involves the use of a knife with a drag or tangential orientation that follows the material's contour and produces accurate cuts. It is ideal for materials with irregular shapes and finds application in the textile industry to cut fabrics. 3. Scissor Slitting utilizes two blades that move in a scissor-like motion to cut the coil. This method is commonly employed for thinner materials, providing excellent control and precision. It is ideal for materials prone to deformation or wrinkling. 4. Razor Slitting involves the use of a single or multiple razor blades positioned perpendicular to the material. It is particularly effective for cutting stretchy or delicate materials, minimizing the risk of tearing or deforming. 5. Crush Cutting applies pressure from a hardened steel roller or an anvil against a softer material, causing it to deform and split along the desired cutting line. It is suitable for materials that are challenging to cut with sharp blades, delivering precise and clean cuts. In conclusion, the choice of coil slitting method depends on the material, desired precision, and specific application requirements. Each method offers unique benefits and can be tailored to meet specific cutting needs, ensuring accurate and efficient coil slitting processes.

Send your message to us

Prime Hot Rolled Steel Sheets in Coils Steel Coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords