High Coating Galvalume Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

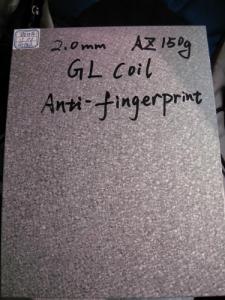

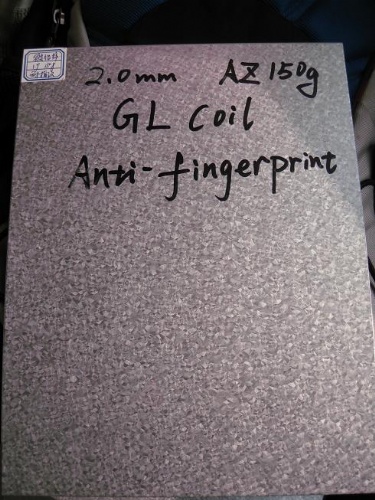

Hot Dipped Galvalume Sheet as per ASTM A 792 CS (Type A), AZ 150, Anti Fingerprint,

~ Regular Spangle, with side one PVC Film

~ AL 55%, ZN 42%, Si > 1.5%

SIZE (MM) (TCT) MOQ (MTS)

1.0 x 1250 x C 100

1.5 x 1250 x C 100

2.0 x 1250 x C 100

COIL ID: 508MM

COIL WEIGHT: 4-6MTS

VALIDITY: 3 WORKING DAYS

PAYMENT: T/T WITH 20% DOWNPAYMENT AND BALANCE AGAINST INVOICE & PACKING LIST

SHIPMENT: 75 DAYS AFTER T/T 20% DOWNPAYMENT

- Q: How are steel coils inspected for coil weight accuracy?

- Steel coils are inspected for coil weight accuracy using weighing scales or load cells. The coils are placed on the scales or load cells, and the weight is measured to ensure it matches the specified weight range.

- Q: How are galvanized steel coils different from regular steel coils?

- In terms of their protective coating, there is a difference between galvanized steel coils and regular steel coils. Galvanized steel coils have a layer of zinc coating, which serves as a barrier against corrosion and rust. This process, called galvanization, involves immersing the steel coils in a bath of molten zinc or applying zinc to the surface using different methods. On the other hand, regular steel coils lack this protective coating, making them more prone to corrosion and rust. The zinc layer on galvanized steel coils not only functions as a physical barrier but also provides sacrificial protection. This means that if the coating is scratched or damaged, the zinc sacrifices itself to shield the underlying steel from corrosion. Consequently, galvanized steel coils are highly durable and suitable for applications that require resistance to harsh environmental conditions. These applications include outdoor construction projects, automotive manufacturing, and the production of household appliances.

- Q: What is the difference between carbon steel and spring steel?? And which is the better one to make swords with??

- All steel has carbon in it. If too much carbon is in the steel it is extremely hard and brittle. Like cast iron. The only difference between iron and steel is the level of carbon. Cast iron is very hard. A drill can barely drill thru it unless you treat it with something like cobalt or titanium nitride. But if you hit cast iron with a hammer very sharply it will break into pieces from the shock. Too low of carbon causes problems though. Steel is very flexible and machinable when it has very low carbon, but it also doesn't wear very well. If you made a sword out of low carbon steel, it would bend very easily and the edge would get dull quick. If you bent it, it wouldn't spring back either. That gets us to spring steel. This is just the right amount of carbon so the steel is very hard and the sword can hold an edge. It also gives it shock resistance. You can bend the sword and it returns to it's original shape. That is why it is called spring steel. The steel resists bending and when it does bend, as long as it isn't to far, it springs back when let go, to it's original shape

- Q: How are steel coils classified based on their thickness?

- Steel coils are classified based on their thickness using a gauge system, where the higher the gauge number, the thinner the coil.

- Q: What is the thickness of a steel coil?

- The thickness of a steel coil can vary depending on the specific application and requirements. However, it typically ranges from a few millimeters to several centimeters.

- Q: Like 49ers. Pittsburgh have long history of steel industry?

- www.okorder A basement waterproofing New Jersey contractor is the one that you need to ensure that your entire home's foundation will not get damped with water and to avoid expensive repairs at the same time.

- Q: How are steel coils made?

- Steel coils are made through a process called hot rolling, where a large slab of steel is heated and passed through a series of rolling mills to gradually reduce its thickness and shape it into a coil.

- Q: How are steel coils used in the manufacturing of automotive doors?

- Steel coils are used in the manufacturing of automotive doors as they serve as the primary raw material for forming the door panels. These coils are processed through various manufacturing techniques such as stamping, cutting, and bending to shape the door panels. The strong and durable nature of steel makes it an ideal material for automotive doors, providing structural integrity and protection to the vehicle.

- Q: How do steel coils contribute to the water and wastewater industry?

- Steel coils contribute to the water and wastewater industry by being used in the construction of pipes, tanks, and other infrastructure. These coils provide strength, durability, and corrosion resistance, ensuring the integrity and longevity of water and wastewater systems. Additionally, steel coils are often utilized in the manufacturing of water treatment equipment and machinery, helping to improve the efficiency and effectiveness of the water and wastewater treatment processes.

- Q: i need a company that sells strong steel doors because my neighbors apartment was broken into. I need a strong steel door for the outside of the home, where you first enter. please list places in the US, or in NY.

- You okorder

Send your message to us

High Coating Galvalume Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords