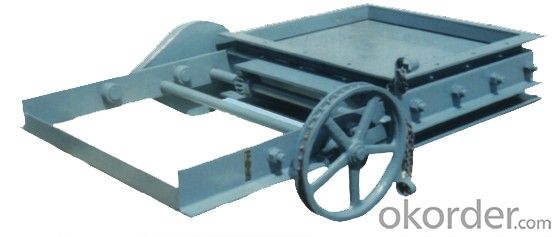

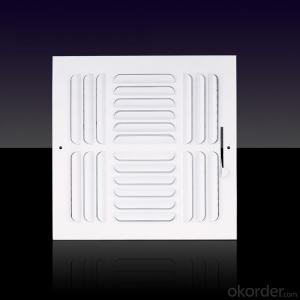

Furnace Fittings -Air Damper

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

GROUP mainly produces the following products:

l Refinery/chemical furnaces, incinerators, coal (liquid) chemical reformers

l Waste heat boilers, thermal medium boilers

l Class A1 /A2 pressure vessels

l Reactors, Heat Exchangers & Towers

l Oil tanks/accessories/mixers, alloy steel precision castings

l Four classes of piping supports and hangers used in fired-electric/thermo-electric/nuclear electric power industries and dampers

l Flue gas/air/coal powder duct and its attachments

l Boiler ancillaries, water treatment devices and so on

GROUP obtains the following certificates:

l Class A Certificate of Engineering Design

l Design License of Pressure Vessel (Class A3)

l Manufacture License of Pressure Vessel (Class A3)

l Design & Manufacture License of Pressure Piping (Class A)

l Manufacture License of Waste heat boilers (Class A), thermal medium boilers

l ISO 9001:2000 Quality Management System

l ASME U and ASME S

l Enterprise Credit: AAA

As the Leading Enterprise of Fired Heaters, Corporation can design and fabricate common Fired Heaters as well as uncommon ones independently such as Reactor Charge Heater for Straight-run Gasoline Hydrogenation Unit (7*104 t/a), 6t/d Testing Unit for Direct Liquefaction, Coal Liquefaction Reactor Heater for Stable Unit of Coal Liquefaction and Hydrogenation, Two-stage Fired Heater for Pyrolysis Gasoline hydrogenation Unit of Ethylene Technical Reform (7.2*105 t/a), Reboiler for Depentanizer of Aromatic Hydrocarbon Unit (2.5*105 t/a), Reboiler for Reboiling Deheptane Tower, Four-in-one Reforming Heater for Reforming Project (2*105 t, 6*105 t, 8*105 t), Acetylene Cracking Heater for PTMEG Unit, etc.

- Q: Selection of heat preservation material for industrial furnace

- Ceramic fiber blanket can be used.Ceramic fiber blanket color white, regular size, set fire, heat insulation, insulation in one. Free from any binding agent.

- Q: Should the industrial furnace shell cool down?

- Normally, the furnace shell temperature of an industrial furnace is below 50 degrees, so there is no need to cool down.

- Q: What are the combustion equipments used in industrial boilers?

- The main auxiliary equipments of the general boiler are: upper coal machine, ash blower, blower, draught fan, economizer, feed pump and water treatment unit. Oil boilers are: oil pumps, burners, tanks and so on.

- Q: What's the role of anchor bricks in industrial furnaces?

- The wall of an industrial furnace or flue is mainly composed of an inner lining layer, a heat insulating layer and an outer wall layer. The lining is a refractory brick, and the outer wall is an ordinary sintered brick.

- Q: Why does the burner of industrial furnace burn occasionally?

- The flameout protection system is made up of burner controller, electromagnetic valve and flame detector, and the flame detection mode is mainly based on the two forms of ultraviolet detection and electrode detection. By utilizing the electric conductivity of the flame, the circuit path of the combustion process generates a weak current, and when the signal amplifier is amplified, the flame is induced to exist, and the small power burner adopts the detection mode more, and is economical and practical.

- Q: How many kinds of industrial electric furnaces are there?

- Industrial furnace according to the heating mode is divided into two categories: one is the fuel furnace, combustion heat with solid, liquid or gaseous fuel in the furnace for heating the workpiece; the second is in the furnace, the furnace converts electrical energy to heat the heat.

- Q: What is the difference between industrial furnace masonry and ordinary masonry?

- Of course, the difference is like the difference between a hog cap and a 100 story building. See the industrial furnace manual.

- Q: How to use industrial furnace equipment?

- The protection device of the exposed transmission department shall be installed with the correct installation position. The structure is reasonable. The wire rope pulley of the furnace car shall be intact and undamaged. All the pulleys and sprockets on the furnace are in good condition, without defects and flexible in rolling.

- Q: Brief introduction to repair of industrial furnace

- The working condition of industrial furnace is very bad. It is affected by high temperature, slag erosion and burden wear. Therefore, its working condition changes quickly and its service life is short.

- Q: What is the difference in structure between industrial furnace and boiler?

- Industrial furnace: main heating, steel and other metal materials, or ore and other materials. An industrial furnace of higher temperature, such as forging or heat treatment. Therefore, the energy consumption is large, and the insulation layer is designed to be thicker, and the structure is designed for the final purpose of the production purpose, the product process and the production efficiency.

Send your message to us

Furnace Fittings -Air Damper

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords