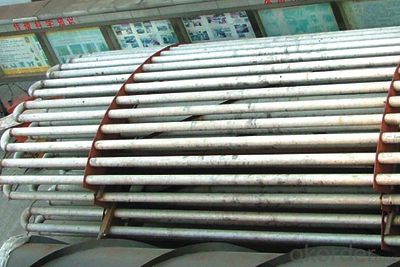

Convection Coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

GROUP mainly produces the following products:

l Refinery/chemical furnaces, incinerators, coal (liquid) chemical reformers

l Waste heat boilers, thermal medium boilers

l Class A1 /A2 pressure vessels

l Reactors, Heat Exchangers & Towers

l Oil tanks/accessories/mixers, alloy steel precision castings

l Four classes of piping supports and hangers used in fired-electric/thermo-electric/nuclear electric power industries and dampers

l Flue gas/air/coal powder duct and its attachments

l Boiler ancillaries, water treatment devices and so on

GROUP obtains the following certificates:

l Class A Certificate of Engineering Design

l Design License of Pressure Vessel (Class A3)

l Manufacture License of Pressure Vessel (Class A3)

l Design & Manufacture License of Pressure Piping (Class A)

l Manufacture License of Waste heat boilers (Class A), thermal medium boilers

l ISO 9001:2000 Quality Management System

l ASME U and ASME S

l Enterprise Credit: AAA

As the Leading Enterprise of Fired Heaters, Corporation can design and fabricate common Fired Heaters as well as uncommon ones independently such as Reactor Charge Heater for Straight-run Gasoline Hydrogenation Unit (7*104 t/a), 6t/d Testing Unit for Direct Liquefaction, Coal Liquefaction Reactor Heater for Stable Unit of Coal Liquefaction and Hydrogenation, Two-stage Fired Heater for Pyrolysis Gasoline hydrogenation Unit of Ethylene Technical Reform (7.2*105 t/a), Reboiler for Depentanizer of Aromatic Hydrocarbon Unit (2.5*105 t/a), Reboiler for Reboiling Deheptane Tower, Four-in-one Reforming Heater for Reforming Project (2*105 t, 6*105 t, 8*105 t), Acetylene Cracking Heater for PTMEG Unit, etc.

- Q: Selection of heat preservation material for industrial furnace

- Micro nano heat insulation board.The thermal conductivity of micro nano heat insulation board is very low, only a fraction of the traditional thermal insulation material, and the insulation effect is very efficient.

- Q: Should the industrial furnace shell cool down?

- The function of furnace shell is beautiful, protective lining, fixed function accessories and so on.

- Q: Heat treatment equipment (industrial furnace), which products generally contain what kind of, which industries need to use heat treatment industrial furnace equipment.

- Heat treatment furnace is mainly for the mechanical processing and casting industry workpiece annealing, quenching, carburizing, quenching and tempering, heat treatment equipment.

- Q: What are the companies in the world that are currently engaged in metallurgical furnaces?

- There are many kinds of furnaces in metallurgical industry,colored and black,smelting and heat treatment are also included.

- Q: What is industrial furnace masonry?

- Masonry industrial furnaces refers to complete materials such as brick kilns in construction process.

- Q: What's the role of anchor bricks in industrial furnaces?

- These layers need to be joined and anchored. Anchor brick is this role. The heat insulation layer at the horizontal section of the flue is mostly a narrow cavity.

- Q: How many kinds of industrial electric furnaces are there?

- Industrial furnace according to the heating mode is divided into two categories: one is the fuel furnace, combustion heat with solid, liquid or gaseous fuel in the furnace for heating the workpiece; the second is in the furnace, the furnace converts electrical energy to heat the heat.

- Q: What is the difference between industrial furnace masonry and ordinary masonry?

- Of course, the difference is like the difference between a hog cap and a 100 story building. See the industrial furnace manual.

- Q: Brief introduction to repair of industrial furnace

- Although the number of industrial furnaces in general machinery plants is not large, the number of large repairs per year accounts for 16%-20% of the total number of repairs for all equipment, and the large repair costs account for about 18%-25% of the total repair cost of all equipment.

- Q: What is an industrial furnace pit?

- The creation and development of industrial kilns play an important role in the progress of mankind. Chinese appeared more perfect in the Shang Dynasty copper smelting furnace, furnace temperature is up to 1200 DEG C, up to 0.8 meters in diameter kiln stove.

Send your message to us

Convection Coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches