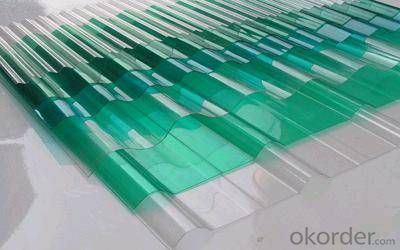

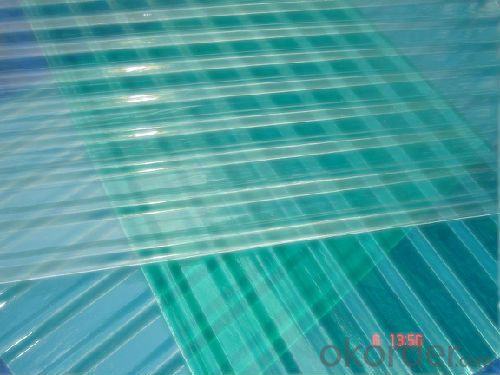

Fiberglass Mat Tissue FRP Roofing Sheet (Panel)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1:Brief Introduction

Although the FRP anti-corrosion panel are produced in the same production line with FRP skylight panel, it has greater and more requirements of the professional technology. There are only a few of the manufacturers who can produce FRP opaque panels in

2:Characteristics

High light transmission

Good weather resistance

High impact resistance

Excellent corrosion resistance

Excellent temperature performance

Excellent sound insulation

Excellent heat stability

3:Technical Specification

Plate matches: match with general prepainted galvanized sheet, galvanized steel

Resin composites: Improved anti-aging SMR198 resin

Fiber reinforcement: E-glass fiber untwisted without glue

Surface treatment: affixing MELINEX301 film

Stiffener line: surface with longitudinal uniform distribution of anti-LAC gluten

Glass fiber: not less than 28%

Unit Weight: 1800g / ㎡, 2400g / ㎡, 3050g / ㎡

Nominal thickness: 1.2 mm, 1.5mm, 2.0mm (tolerance ≤ 10%)

Temperature limits: -60 ℃ ~ +130 ℃

Transmittance (1.5mm): 72% ± 2% (fog white, sky blue, water green), 52% ± 2% (white porcelain)

UV-rate: 99%

Tensile strength: 90Mpa

Flexural strength: 160 Mpa

Elongation: 1.9%

Pap hardness: ≥ 50

Thermal expansion coefficient: 1.5 ~ 3.2 * 10-5 / K

Thermal conductivity: K = 0.23W / m * K

Guarantee: 15 years

NOTE: In special cases, the surface film varieties vary according to needs, such as Melinex389, PT055 and so on.

FAQ:

What is your minimum order quantity?

Our MOQ is 500 Square Meter/Square Meters (Without limiting sizes and specification)

2. How can I get samples to check your quality?

We can offer samples for free.

3. Can you do the production as customized?

Yes, we have a professional technique team, we could produce the glass depends on your requirements.

- Q: Is fiberglass mat tissue easy to install?

- Yes, fiberglass mat tissue is relatively easy to install. It is a lightweight and flexible material that can be easily cut and shaped to fit any surface. It can be applied using various methods such as spraying, rolling, or brushing on adhesive. The tissue is also self-adhesive, which makes it even easier to install as it can easily stick to the desired surface. Additionally, fiberglass mat tissues are typically designed to be water-resistant and provide excellent insulation properties, making them a popular choice for a wide range of applications. Overall, with proper preparation and following the manufacturer's instructions, installing fiberglass mat tissue can be a straightforward and hassle-free process.

- Q: How long does fiberglass mat tissue last?

- The lifespan of fiberglass mat tissue can vary depending on various factors such as its quality, usage, and exposure to external conditions. Generally, fiberglass mat tissue is designed to be highly durable and long-lasting. When properly installed and maintained, it can typically last for several decades. However, it is important to note that fiberglass mat tissue can deteriorate over time due to environmental factors such as UV exposure, moisture, and temperature fluctuations. Continuous exposure to harsh weather conditions, extreme temperatures, or chemicals can accelerate the degradation process. To maximize the lifespan of fiberglass mat tissue, it is crucial to follow the manufacturer's guidelines for installation, maintenance, and periodic inspections. Regular inspections can help identify any signs of wear, damage, or degradation early on, allowing for timely repairs or replacements. It is recommended to consult with a professional or the manufacturer for specific information regarding the expected lifespan of a particular fiberglass mat tissue, as it can vary depending on the specific product and its intended application.

- Q: Is fiberglass mat tissue fire-resistant?

- Yes, fiberglass mat tissue is fire-resistant.

- Q: How does fiberglass mat tissue perform in high temperatures?

- Fiberglass mat tissue performs well in high temperatures due to its inherent heat resistance properties. The mat is typically made from glass fibers that are woven together, creating a strong and durable material. These glass fibers have a high melting point, allowing the fiberglass mat tissue to withstand elevated temperatures without deforming or losing its structural integrity. When exposed to high temperatures, fiberglass mat tissue does not shrink, warp, or become brittle like other materials might. It retains its dimensional stability and mechanical strength, making it suitable for various applications in industries such as automotive, aerospace, construction, and insulation. Additionally, fiberglass mat tissue acts as a thermal insulator, offering protection against heat transfer. It can effectively resist heat conduction and radiation, helping to maintain the desired temperature in a given environment or prevent heat damage to surrounding components. Furthermore, fiberglass mat tissue is non-combustible, meaning it does not burn or produce toxic gases when exposed to fire. This makes it a reliable choice for applications that require fire resistance, such as fireproofing insulation or protective barriers. In summary, fiberglass mat tissue performs exceptionally well in high temperatures. Its heat resistance, dimensional stability, mechanical strength, thermal insulation properties, and non-combustible nature make it an excellent material for use in demanding environments where elevated temperatures are present.

- Q: Is fiberglass mat tissue suitable for aerospace interiors?

- Fiberglass mat tissue is indeed a suitable material for aerospace interiors. This material is both lightweight and extremely versatile, providing exceptional strength and durability. Its widespread use in aerospace applications is due to its ability to meet rigorous fire safety standards, including low smoke and toxicity emissions. Furthermore, fiberglass mat tissue exhibits resistance to moisture, chemicals, and temperature fluctuations, making it an ideal option for the challenging conditions found within an aircraft cabin. Its exceptional sound insulation properties further contribute to its suitability for aerospace interiors, guaranteeing a pleasant and noise-free environment for passengers. All in all, fiberglass mat tissue offers a dependable and effective solution for aerospace interior applications.

- Q: Is fiberglass mat tissue suitable for insulation in hospitals?

- Yes, fiberglass mat tissue is suitable for insulation in hospitals. It provides excellent thermal insulation properties and is fire-resistant, which is crucial for ensuring the safety of patients and staff in healthcare environments. Additionally, fiberglass mat tissue is a durable and cost-effective option for insulation, making it a practical choice for hospitals.

- Q: What are the different weights available for fiberglass mat tissue?

- Fiberglass mat tissue, which is widely used in various industries including construction, automotive, and marine, comes in different weights or thicknesses to cater to different applications and requirements. The weight of fiberglass mat tissue is usually measured in grams per square meter (gsm) or ounces per square yard (oz/yd²). Typically, the weights available for fiberglass mat tissue range from around 30 gsm (1 oz/yd²) to 150 gsm (5 oz/yd²) or even higher. The weight of the tissue determines its strength, rigidity, and durability. Lightweight fiberglass mat tissue, such as those weighing around 30-50 gsm (1-1.5 oz/yd²), is commonly used for applications where a high level of flexibility and conformability is required. These lighter weight tissues are often used in the production of laminates, reinforcing materials, and lightweight composites. Medium weight fiberglass mat tissue, usually ranging from 70 gsm (2 oz/yd²) to 100 gsm (3 oz/yd²), provides a balance between flexibility and strength. It is frequently used in applications such as roofing, insulation, and wall panels, where structural integrity and thermal insulation properties are important. Heavyweight fiberglass mat tissue, which can weigh between 120 gsm (4 oz/yd²) and 150 gsm (5 oz/yd²) or more, offers excellent strength and rigidity. This type of tissue is commonly used in demanding applications like boat hulls, automotive body parts, and industrial equipment, where durability and resistance to impact and stress are crucial. It is important to note that the availability of different weights of fiberglass mat tissue may vary depending on the manufacturer and the specific requirements of the application. In some cases, custom weights can be produced to meet unique project needs. In conclusion, fiberglass mat tissue comes in a range of weights to suit different applications. Choosing the appropriate weight is crucial to ensure optimal performance and long-term durability in various industries.

- Q: What is the moisture absorption rate of fiberglass mat tissue?

- The moisture absorption rate of fiberglass mat tissue is relatively low, as fiberglass is known for its water-resistant properties.

- Q: What are the advantages of using fiberglass mat tissue in construction?

- Using fiberglass mat tissue in construction offers several advantages. Firstly, it provides excellent reinforcement and strength to construction materials, enhancing their durability and resistance to cracks, impacts, and weathering. This makes it an ideal choice for reinforcing concrete, roofing materials, and composite products. Secondly, fiberglass mat tissue is lightweight and easy to handle, making it convenient for construction purposes. Unlike heavy steel reinforcements, it can be easily cut, shaped, and applied without requiring specialized tools. This saves both labor and time, resulting in cost savings. Additionally, fiberglass mat tissue is non-corrosive and non-conductive, making it suitable for various environments. It remains unaffected by rust or degradation, even in harsh conditions, ensuring the longevity and reliability of the construction. Moreover, it does not conduct electricity, which is crucial for applications where electrical conductivity must be avoided. Furthermore, fiberglass mat tissue offers excellent thermal insulation properties. It acts as a barrier to heat transfer, creating a comfortable and energy-efficient interior environment. This can lead to reduced heating and cooling costs, making it a sustainable and cost-effective choice. Lastly, fiberglass mat tissue is resistant to fire and chemicals. It does not burn or release toxic fumes when exposed to flames, providing an added level of safety in construction. It also withstands many chemicals, including acids and alkalis, making it suitable for corrosive environments such as chemical plants or industrial facilities. In conclusion, the benefits of using fiberglass mat tissue in construction include enhanced reinforcement, lightweight and easy handling, non-corrosive and non-conductive properties, thermal insulation, fire resistance, and chemical resistance. These advantages make it a versatile and reliable material for various construction applications.

- Q: Can fiberglass mat tissue be used for reinforcing concrete?

- Yes, fiberglass mat tissue can be used for reinforcing concrete. Fiberglass mat tissue is a lightweight and flexible material that is often used in construction projects to enhance the strength and durability of concrete structures. It can be embedded within the concrete to provide additional reinforcement and prevent cracks from forming over time. The fiberglass mat tissue is typically made from high-quality glass fibers that are woven together to form a strong and stable material. Its excellent tensile strength and resistance to corrosion make it an ideal choice for reinforcing concrete and improving its overall performance. Whether it is used in sidewalks, driveways, or other concrete structures, fiberglass mat tissue can significantly enhance the strength and longevity of the concrete.

Send your message to us

Fiberglass Mat Tissue FRP Roofing Sheet (Panel)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords