Fiberglass Mat Tissue E Glass Chopped Strand Mat for Lamination

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description of Powder Binder E glass Chopped Strand Mat for Fixed Table Lamination

Powder Binder E glass Chopped Strand Mat for Fixed Table Lamination is an unwoven fabrics consisting of randomly distributed chopped strands held together with powder binder.

Powder Chopped Strand Mats are compatible with unsaturated polyester, vinyl ester, phenol and epoxy resins.

This product is special designed and produced for the FRP sheet/panel fixed table lamination. The typical end-use applications include various Gel-coat panels and sheet, the end application is for the cold warehouse, cold trucks body etc.

Specification of Powder Binder E glass Chopped Strand Mat for Fixed Table Lamination

Property | Glass type | Weight(g/m2) | Width 200~3300 | Roll Weight | Moisture Content /% | Combustible Content /% | Breakage Strength /N |

Test Method | GB/T 1549 | ISO3374:2000 | ISO3374 | GB/T17470-1998 | ISO3344:1997 | ISO1887:1995 | ISO3342 |

EMC 250 | E-GLASS | 225±22 | ±5 | 6~150 | <0.2 | 5.0±0.6 | ≥150 |

EMC 300 | E-GLASS | 300±30 | ±5 | 6~180 | <0.2 | 4.0±0.6 | ≥190 |

EMC 375 | E-GLASS | 375±37 | ±5 | 6~180 | <0.2 | 4.0±0.6 | ≥200 |

EMC 450 | E-GLASS | 450±45 | ±5 | 6~180 | <0.2 | 3.8±0.6 | ≥200 |

Characteristics of Powder Binder E glass Chopped Strand Mat for Fixed Table Lamination

1.Uniform density ensures consisttent fiberglass content and mechanical properties of the composites products;

2.Uniform powder distribution ensures good mat integrity, little loose fibers and small roll diameter;

3.Fast and consistent wet-out speed in resins and rapid air lease reduce resin consumption and production cost, and enhances productivity and mechanical properties of the end products.

4, The composite products have high dry and wet tensile strength and good transparency.

5, High strength with stiff mat for panel laminating.

Package:

1, the Mat roll will be wrapped in PVC/PE film, and then packed in wooden boxes, fasten by steel strip outside of the wooden boxes;

2, Horizontally placed in wooden boxes:

3 rolls*3rolls

There are isolated beams between the roll layers to protect the mat from damage.

FAQ:

1. Why Choose us?

CNBM is a stated owned company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

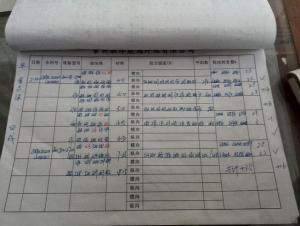

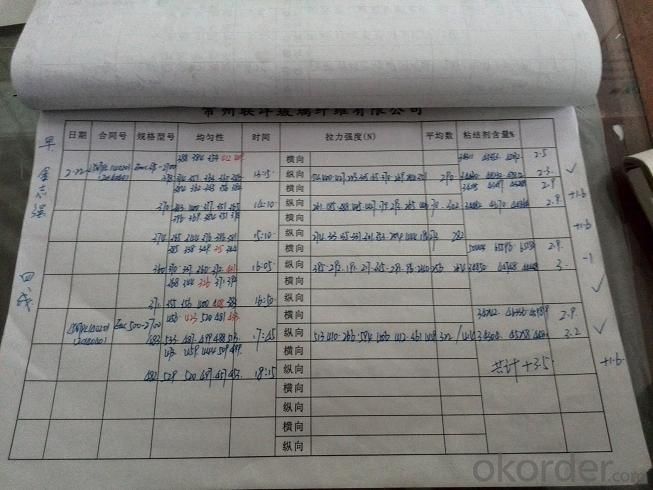

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

3. What is your MOQ?

Our MOQ is one pallet.

4. Can you provide sample?

Yes, samples are in stock. we can offer free sample for you.

5. Payment terms?

We can accept L/C, T/T etc.

6. Do you offer OEM service?

Yes, we can print customers’ logo on the packaging;

And the size and specification can be produced and design according to your demand.

7. What is the Production Lead Time?

1 *40HQ each day.

- Q: Is fiberglass mat tissue safe to handle?

- Yes, fiberglass mat tissue is generally safe to handle. However, it is important to take certain precautions when handling fiberglass to minimize any potential risks. Fiberglass mat tissue is made up of fine fibers of glass, and if not handled properly, these fibers can become airborne and may cause irritation to the skin, eyes, and respiratory system. To ensure safety, it is recommended to wear personal protective equipment such as gloves, safety goggles, and a dust mask when handling fiberglass mat tissue. This will help prevent direct contact with the skin, eyes, and inhalation of any loose fibers. It is also advisable to work in a well-ventilated area to reduce the concentration of airborne fibers. In addition, it is essential to handle fiberglass mat tissue with care to prevent any physical injuries. The fibers can be sharp and may cause cuts or abrasions if mishandled. It is advisable to use appropriate tools and techniques to cut, shape, or manipulate the material. Furthermore, it is important to follow proper disposal guidelines for fiberglass waste. Avoid sweeping or vacuuming the area where fiberglass mat tissue has been handled, as this can disperse fibers into the air. Instead, use damp cleaning methods or specialized vacuum cleaners with HEPA filters to contain the fibers and reduce the risk of exposure. By following these safety precautions and handling guidelines, the risks associated with fiberglass mat tissue can be effectively minimized, ensuring safe handling and use of the material.

- Q: Is fiberglass mat tissue resistant to alkalis?

- Yes, fiberglass mat tissue is resistant to alkalis. It is commonly used in construction and industrial applications where it may come into contact with alkaline substances such as cement or concrete. The fiberglass mat tissue is designed to have a high resistance to alkalis, ensuring its durability and longevity in these environments. This resistance is due to the chemical composition and structure of the fiberglass, which allows it to withstand the corrosive effects of alkalis without degradation. Therefore, fiberglass mat tissue is a reliable choice for projects that involve exposure to alkalis.

- Q: Is fiberglass mat tissue suitable for aerospace interiors?

- Fiberglass mat tissue is indeed a suitable material for aerospace interiors. This material is both lightweight and extremely versatile, providing exceptional strength and durability. Its widespread use in aerospace applications is due to its ability to meet rigorous fire safety standards, including low smoke and toxicity emissions. Furthermore, fiberglass mat tissue exhibits resistance to moisture, chemicals, and temperature fluctuations, making it an ideal option for the challenging conditions found within an aircraft cabin. Its exceptional sound insulation properties further contribute to its suitability for aerospace interiors, guaranteeing a pleasant and noise-free environment for passengers. All in all, fiberglass mat tissue offers a dependable and effective solution for aerospace interior applications.

- Q: How does fiberglass mat tissue perform in terms of thermal conductivity?

- Fiberglass mat tissue has low thermal conductivity, meaning it is a poor conductor of heat.

- Q: What is the weathering resistance of fiberglass mat tissue?

- The weathering resistance of fiberglass mat tissue is generally considered to be high. Fiberglass mat tissue is made from a combination of fiberglass strands and a binder material, such as polyester or acrylic. This combination creates a strong and durable material that is resistant to various weathering factors, including exposure to sunlight, moisture, and temperature fluctuations. The fiberglass strands in the mat tissue provide excellent mechanical strength, preventing the material from breaking down under external stress or pressure. This strength helps the mat tissue withstand the impact of wind, rain, and other weather elements without significant damage. Additionally, the binder material used in the manufacturing process of fiberglass mat tissue is often formulated to be resistant to UV radiation. This UV resistance helps to protect the material from degradation and color fading caused by prolonged exposure to sunlight. It also helps to maintain the structural integrity and strength of the mat tissue over time. Furthermore, fiberglass mat tissue is also resistant to moisture and water absorption. This resistance prevents the material from becoming weakened or deteriorated when exposed to rain, humidity, or other moisture sources. As a result, the mat tissue remains intact and retains its performance properties even in wet or humid conditions. Overall, the weathering resistance of fiberglass mat tissue is considered to be excellent, making it a popular choice for various applications where durability and longevity in outdoor environments are required.

- Q: Can fiberglass mat tissue be used for insulating refrigeration units?

- Yes, fiberglass mat tissue can be used for insulating refrigeration units. Fiberglass mat tissue is a lightweight material that has excellent thermal insulation properties. It is commonly used in various applications where insulation is required, including refrigeration units. The fiberglass mat tissue helps to reduce heat transfer, keeping the internal temperature of the refrigeration unit stable and preventing any external heat from affecting the stored items. Additionally, fiberglass mat tissue is resistant to moisture, which is important in refrigeration units to prevent condensation and maintain the efficiency of the cooling system. Overall, fiberglass mat tissue is a suitable and effective choice for insulating refrigeration units.

- Q: Can fiberglass mat tissue be used for making lightweight furniture?

- No, fiberglass mat tissue is not typically used for making lightweight furniture. It is primarily used as a reinforcement material in applications such as insulation, automotive parts, and construction, but not for furniture production.

- Q: How is fiberglass mat tissue different from fiberglass cloth?

- Fiberglass mat tissue and fiberglass cloth, despite being woven glass fiber materials, exhibit distinct dissimilarities. Fiberglass mat tissue, an unwoven substance, comprises glass fibers randomly arranged and held together by a binding agent. It predominantly serves as a reinforcement layer in composite materials like fiberglass reinforced plastic (FRP) and fiberglass reinforced concrete (FRC). The random fiber orientation enhances the composite structure's robustness and stability. Notably, fiberglass mat tissue finds widespread usage in applications necessitating strength and rigidity, such as boat hulls or automotive components. In contrast, fiberglass cloth, a woven material, is created by interlacing glass fibers in a specific pattern. It is commonly employed in situations where flexibility and conformability are essential, such as the construction of surfboards or within the aerospace industry. By allowing precise and controlled fiber placement, fiberglass cloth facilitates the production of intricate shapes and attains a superior level of detail in the final product. Ultimately, the primary disparity between fiberglass mat tissue and fiberglass cloth lies in their structural characteristics and intended applications. While fiberglass mat tissue offers strength and stability, fiberglass cloth provides flexibility and conformability. The selection between these materials hinges on the project's specific requirements and the desired outcome.

- Q: What are the key properties of fiberglass mat tissue?

- Fiberglass mat tissue is a versatile material that possesses several key properties. Firstly, it is made from fine glass fibers that are randomly oriented and bonded together with a binder. This random orientation allows for greater strength and flexibility compared to other materials. One key property of fiberglass mat tissue is its high tensile strength. It can withstand significant amounts of pulling or stretching forces without breaking, making it ideal for applications that require durability and resistance to mechanical stress. Another important property is its excellent thermal insulation capabilities. Fiberglass mat tissue has a low thermal conductivity, meaning it can effectively prevent the transfer of heat. This property makes it suitable for use in insulation applications where it helps to conserve energy and maintain a stable temperature. Fiberglass mat tissue also exhibits good chemical resistance. It is not easily affected by exposure to chemicals, acids, or alkaline substances. This property makes it a suitable choice for applications such as chemical storage tanks or pipes where resistance to corrosion is required. Furthermore, fiberglass mat tissue has excellent moisture resistance. It does not absorb water easily, which makes it resistant to rot and decay. This property makes it suitable for outdoor applications or in environments with high humidity. Lastly, fiberglass mat tissue is lightweight and easy to handle. It can be easily cut, shaped, and installed, making it a convenient material for various applications. In summary, the key properties of fiberglass mat tissue include high tensile strength, thermal insulation capabilities, chemical resistance, moisture resistance, and lightweight. These properties make it a versatile material that can be used in a wide range of applications such as construction, automotive, aerospace, and marine industries.

- Q: Can fiberglass mat tissue be used for repairing fiberglass RVs?

- Yes, fiberglass mat tissue can be used for repairing fiberglass RVs. It is commonly used for reinforcing and repairing fiberglass structures, including RVs, due to its strength and compatibility with fiberglass materials.

Send your message to us

Fiberglass Mat Tissue E Glass Chopped Strand Mat for Lamination

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords