FRP Roofing Panel SMC Pressed Valve Chamber Cover with Hydraulic System

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

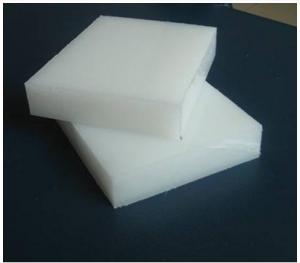

Introduction

SMC and BMC are abbreviations of respectively Sheet Molding Compound and Bulk Molding Compound. SMC and BMC form a family of structural, fiber reinforces thermosetting resins. SMC and BMC are intermediate materials from which a large variety of products can be manufactured by compression molding or injection molding. Base materials of SMC and BMC are, generally spoken, unsaturated polyester resins, glass and mineral filler materials, such as chalk or aluminum trihydrate. The composition of the compounds can be adapted to the application where it is used for. Specific properties such as flame retardancy, surface quality and paintability can be achieved by adding specific, functional materials. SMC and BMC product are used in a very broad range of applications

Product Description

1. Y27 Series Frame-type Hydraulic Press is a kind of multifunctional precision machine which has high speed.

2. Optimized design, the frame is entirely welded with steel plates, and treated to relive stress by tempering for high precision.

3. Cartridge valve equipped for hydraulic control system, reliable, durable and less hydraulic shock, shorter connection pipeline and fewer release points.

4. Centralized button control system, with adjustment, hand and semi-auto operation modes at operator’s choice (set-stroke single and set pressure single).

5. Four-angle and eight-side guide rail in high precision and with strong capacity against deflection, concentrated lubrication.

6. New type of oil cylinder sealing components marked by high reliability and long service life.

7. Sliding blocks operating in high speed, ensuring high efficiency.

8. The slide operating pressure, no-load quick travel and low-speed movement can be adjusted according to technological requirements.

9. Hydraulic cushion is fitted beneath the worktable; adequate knockout hole and hydraulic cushion are prepared on the plate of worktable with the operating modes including drawing, ejection and no ejection.

10. The working speed of this equipment is 3 to 4 times faster than that of Y41. It employs eight-side guide device and ejecting device, which can automatically eject workpieces with accurate guiding and fast speed.

11. The drawing device can be added to this equipment in order to change moulds easily. But the stretching of large metal parts needs to add hydraulic cushion to this equipment.

Advantages

Reduce the cost of localization

Vibration and noise reduction

Integration respirator filler cap

Sealing performance

Application

1. It is suitable for the press fitting and stretch forming of metal and plastic products as well as the movements of coining and overprinting.

2. It mainly applies to the fields of machine tool, engineering machinery, bearings, washing machine, automobile parts, motor components and powder metallurgy.

3. It is suitable for the molding of plastic products, such as DMC and BMC.

4. The machine, with a high degree of automatization, is particularly suitable for the mass production of parts. And it can be used as assembly line with several such equipments.

Specification

Item | Unit | Y27-500 | |

Nominal Force | KN | 5000 | |

Return Force | KN | 900 | |

Ram Stroke | mm | 900 | |

Daylight | mm | 1400 | |

Cushion Force | KN | 2000 | |

Cushion Return force | KN | 780 | |

Cushion Stroke | mm | 350 | |

Ram Speed | Idle Stroke | mm/s | 150 |

Pressing | mm/s | 10-22 | |

Return | mm/s | 120 | |

Cushion Speed | Knock out | mm/s | 55 |

Return | mm/s | 140 | |

Table Size | LR | mm | 2200 |

FB | mm | 1600 | |

Cushion Size | LR | mm | 1720 |

FB | mm | 1120 | |

Overall Dimensions | LR | mm | 4700 |

FB | mm | 3100 | |

Height above the floor | mm | 5800 | |

Power Motor | KW | 2*30 | |

Total Weight(Approx) | KG | 57000 | |

FAQ

1.Which country do you mainly export to?

A: Our products are very popular in Mid East, India, South East Asia, Latin America, Africa.

2.Q: What’s the advantage of you compared with other suppliers experienced in foreign trade?

A: We have been specialized in FRP products for over decades years and approved by many domestic companies. Except for our quality and price, we’re also able to give you the best service.

- Q: Can FRP roofing panels be used in modular construction?

- Yes, FRP roofing panels can be used in modular construction. FRP, which stands for Fiber Reinforced Polymer, is a strong and durable material that is commonly used in construction due to its lightweight nature and resistance to corrosion and weathering. In modular construction, where buildings are constructed off-site in sections or modules and then transported to the final location for assembly, the use of FRP roofing panels can offer several advantages. Firstly, the lightweight nature of FRP panels makes them easier to handle and transport, contributing to the efficiency of modular construction. Additionally, FRP roofing panels provide excellent insulation properties, helping to regulate temperature and reduce energy consumption in modular buildings. This is particularly beneficial in modular construction, as maintaining energy efficiency is crucial for sustainable and cost-effective building practices. Moreover, FRP roofing panels are highly weather-resistant, with the ability to withstand extreme temperatures, UV rays, and moisture. This makes them a reliable choice for modular construction, where the durability of the building materials is important, especially during transportation and assembly. Lastly, FRP roofing panels offer design flexibility, as they can be manufactured in various colors, finishes, and profiles to match the aesthetic requirements of the modular construction project. Overall, FRP roofing panels are a suitable choice for modular construction due to their lightweight nature, insulation properties, durability, and design flexibility. Their use can enhance the efficiency, sustainability, and aesthetics of modular buildings.

- Q: Are FRP roofing panels suitable for both residential and commercial buildings?

- Yes, FRP roofing panels are suitable for both residential and commercial buildings. They provide durability, weather resistance, and energy efficiency, making them a versatile choice for various construction projects. Additionally, FRP panels are lightweight, easy to install, and require minimal maintenance, making them a cost-effective solution for both residential and commercial applications.

- Q: Are FRP roofing panels resistant to saltwater corrosion?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are generally resistant to saltwater corrosion. FRP is known for its exceptional resistance to various chemicals, including saltwater. This makes it a suitable choice for roofing applications in coastal areas or locations with high salt content in the air. The corrosion-resistant properties of FRP panels ensure that they can withstand the effects of saltwater exposure over an extended period without deteriorating or losing their structural integrity. However, it is important to note that the level of resistance may vary depending on the specific composition and quality of the FRP panels. It is always advisable to consult with manufacturers or experts in the field to ensure that the chosen FRP roofing panels are suitable for the intended application and environment.

- Q: What colors are available for FRP roofing panels?

- FRP roofing panels are available in a variety of colors, including but not limited to white, gray, green, blue, and translucent options.

- Q: Are FRP roofing panels resistant to damage from hail or wind-driven debris?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are known for their high resistance to damage from hail or wind-driven debris. They have excellent impact resistance and can withstand severe weather conditions, making them a durable choice for roofing applications.

- Q: Can FRP roofing panels be used for hospitals?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for hospitals. FRP panels are a popular choice for roofing applications due to their durability, lightweight nature, and resistance to corrosion and UV radiation. These qualities make FRP panels suitable for various environments, including hospitals. In hospitals, it is crucial to have roofing materials that are not only strong and long-lasting but also provide a safe and hygienic environment. FRP panels meet these requirements as they are resistant to mold, mildew, and bacteria growth. They are also easy to clean and maintain, which is essential in healthcare settings where cleanliness is of utmost importance. Furthermore, FRP roofing panels offer excellent insulation properties, helping to regulate temperature and reduce energy consumption in hospitals. This is especially beneficial in maintaining a comfortable and controlled indoor environment for patients, staff, and equipment. Additionally, FRP panels can be customized to fit specific design requirements, allowing hospitals to create aesthetically pleasing roofs that enhance the overall look of the facility. Overall, FRP roofing panels are a suitable choice for hospitals due to their durability, resistance to environmental factors, ease of maintenance, and ability to provide a safe and hygienic environment.

- Q: Can FRP roofing panels be cut to fit specific dimensions?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be cut to fit specific dimensions. FRP panels are known for their flexibility and can easily be cut to the desired size using basic cutting tools such as a circular saw or a jigsaw. It is important to take appropriate safety precautions while cutting FRP panels, such as wearing protective eyewear and gloves. Additionally, it is recommended to measure and mark the dimensions accurately before cutting to ensure a precise fit. Overall, FRP roofing panels offer the convenience of customization, allowing them to be easily cut to fit specific dimensions as required.

- Q: Can FRP roofing panels be used for pergolas or outdoor seating areas?

- Certainly, pergolas or outdoor seating areas can make good use of FRP (Fiberglass Reinforced Plastic) roofing panels. Renowned for their durability, lightweight composition, and ability to withstand diverse weather conditions, FRP panels emerge as an exceptional selection for outdoor structures. They provide essential protection against the sun, rain, and other elements, thus ensuring the creation of a comfortable and enjoyable space. Moreover, FRP panels come in a variety of colors and styles, allowing for customization that aligns with the desired aesthetic of your pergola or seating area. Ultimately, FRP roofing panels prove themselves to be a dependable and pragmatic choice for elevating the functionality and visual appeal of outdoor spaces.

- Q: Are FRP roofing panels suitable for residential complexes?

- Residential complexes can indeed utilize FRP (Fiberglass Reinforced Plastic) roofing panels. These panels have gained popularity in residential applications because they offer a multitude of benefits. Firstly, FRP panels are lightweight, making them easy to handle and install. This not only reduces labor costs but also expedites the installation process. Moreover, FRP roofing panels possess high durability and are resistant to various weather conditions. They can endure extreme temperatures, UV radiation, and even hail, ensuring long-lasting protection for residential complexes. Additionally, FRP roofing panels are non-corrosive, which means they will not rust or deteriorate over time. This characteristic is particularly advantageous in coastal areas or regions with high humidity levels. Furthermore, homeowners can choose from a wide range of colors and designs when it comes to FRP panels. This allows them to select a style that complements the overall aesthetics of their residential complex. Another noteworthy advantage of FRP roofing panels is their exceptional insulation properties. By regulating the temperature inside the building, they aid in reducing energy consumption and lowering utility bills. Lastly, compared to other roofing materials such as metal or asphalt, FRP panels are cost-effective. They strike a balance between affordability and performance, making them a practical choice for residential complexes. To sum it up, FRP roofing panels are an ideal option for residential complexes due to their lightweight nature, durability, weather resistance, non-corrosive properties, aesthetic options, insulation capabilities, and cost-effectiveness. These factors establish FRP panels as a reliable and practical roofing solution for residential applications.

- Q: How do FRP roofing panels perform in terms of energy efficiency?

- FRP roofing panels have gained a reputation for their outstanding energy efficiency. These panels have been specifically designed to offer insulation and limit the transfer of heat, resulting in a decrease in energy consumption and improved thermal performance. The insulation value of FRP roofing panels is one of the main factors contributing to their energy efficiency. These panels are manufactured using multiple layers of fiberglass and other insulating materials, which form a protective barrier that prevents heat from escaping in cold weather and entering in hot weather. This insulation capability helps to maintain a consistent indoor temperature, reducing the need for excessive heating or cooling and ultimately lowering energy bills. In addition, FRP roofing panels often come with a UV-protective coating that reflects solar radiation and reduces heat absorption. This reflective property further enhances energy efficiency by minimizing the amount of heat transferred into the building, particularly in areas with intense sunlight and high temperatures. Furthermore, the lightweight nature of FRP roofing panels makes them easy to install, resulting in a quick and efficient installation process. This not only saves time and labor costs but also reduces the likelihood of air leakage and heat loss commonly associated with more complex roofing systems. Overall, FRP roofing panels are highly efficient in terms of energy consumption. Their insulation properties, UV-reflective coatings, and ease of installation make them an ideal choice for buildings looking to reduce energy usage, enhance thermal insulation, and lower overall energy costs.

Send your message to us

FRP Roofing Panel SMC Pressed Valve Chamber Cover with Hydraulic System

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords