FRP Roofing Panel for Houses - Corrugated Metal Roof Sheet Manufacturing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

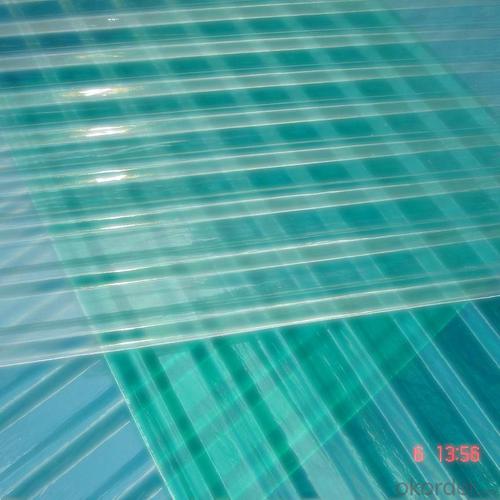

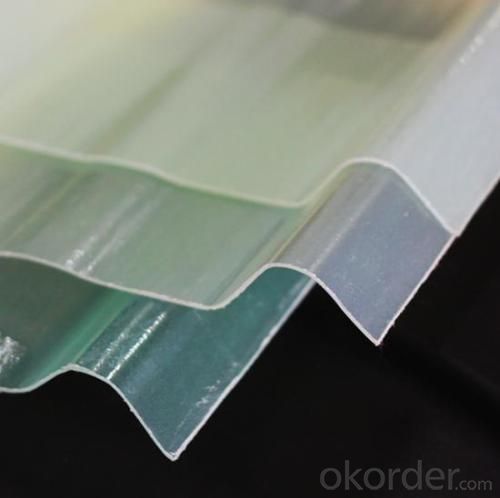

FRP GRP Fiberglass Glassfiber Corrugated Roofing is a patent of our company, not like other FRP products, it is produced without yarn, instead, we use mat only. Therefore, the corrugated sheet is more strong in both horizontal and vertical direction.

Cold rolled sheet has superb sheet shape and surface quality with good flatness and surface finish. The surface of the cold sheet is clean and bright and easy for coating. The varieties of cold rolled sheet are widely used in galvanized substrates, home appliances, tubing, automobiles, building, enamels and other industries.

FEATURES

a. anti-corrosion, non-rusty

b. lightweight and high strength

c. anti-flammable

d. anti-fatigue

e. anti-slippery and safety

f. anti-ageing

g. easy to installation and maintenance

h. excellent electromagnetism property

SPECIFICATION

| Products Name | Manufacture corrugated metal roof / zinc roof / roofing sheet for houses |

THICKNESS | 0.14-0.5MM |

WIDTH | 765MM-->665MM 900MM-->800MM 1000MM-->900MM |

ALUZINC | ALUZINC ROOFING CAN BE SUPPLIED. |

MATERIAL | SGCC,DC51D,DX51D,DX52D |

SPANGLE | ZERO, REGULAR, NORMAL,BIG SPANGLE. |

SURFACT TREATMENT | CHROMATED, OILED, NON-OILED, DRY. |

HARDNESS | SOFT, HARD, FULL HARD. |

PICTURES

- Q: Are FRP roofing panels soundproof?

- No, FRP roofing panels are not soundproof. While they may provide some level of sound insulation, they are not designed or manufactured specifically for soundproofing purposes.

- Q: Can FRP roofing panels be installed on historical or listed buildings?

- Yes, FRP roofing panels can be installed on historical or listed buildings. However, it is important to consult with conservation officers or relevant authorities to ensure that the installation is in compliance with preservation guidelines and regulations specific to the building's historical or listed status.

- Q: Can FRP roofing panels be used in residential applications?

- Residential applications can indeed utilize FRP (Fiberglass Reinforced Plastic) roofing panels. These panels are highly favored in both commercial and residential roofing due to their durability, lightweight properties, and cost-effectiveness. They find common use in various structures such as carports, patio covers, sheds, and more. FRP roofing panels offer exceptional protection against weather elements like UV rays, rain, and snow. Their resistance to corrosion, impact, and fire makes them a reliable choice for residential purposes. Moreover, they boast a lengthy lifespan, require minimal upkeep, and are effortless to install. The versatility of FRP roofing panels is one of their key advantages. They come in an array of colors, profiles, and textures, allowing homeowners to select a style that suits their aesthetic preferences. These panels can also be customized to fit specific sizes and shapes, ensuring a perfect fit for any residential structure. Nevertheless, it is crucial to note that FRP panels may not be suitable for all residential applications. While they are commonly used for low-slope roofs or structures lacking complex architectural features, they may not be the optimal choice for steep-slope roofs. It is advisable to consult a roofing professional to determine the suitability of FRP panels for your specific residential application. All in all, FRP roofing panels can serve as a practical and cost-effective solution for residential roofing needs, offering durability, weather resistance, and aesthetic appeal.

- Q: What is the weight capacity of FRP roofing panels?

- The weight capacity of FRP roofing panels can differ depending on the particular product and its design. Typically, FRP roofing panels are renowned for being lightweight and possessing high strength characteristics, making them appropriate for a range of applications. The weight capacity of FRP roofing panels usually falls between 1 and 1.5 pounds per square foot. Nevertheless, it is crucial to refer to the manufacturer's specifications and guidelines for the specific FRP roofing panel in use to ascertain its precise weight capacity. Furthermore, when determining the weight capacity of FRP roofing panels, factors such as the installation method, support structure, and load distribution should also be taken into account.

- Q: Can FRP roofing panels be used for shopping malls?

- Yes, FRP roofing panels can be used for shopping malls. They are a durable and lightweight roofing solution that can provide protection from weather elements while allowing natural light transmission. FRP panels are also resistant to corrosion, UV rays, and fire, making them suitable for commercial buildings like shopping malls.

- Q: Can FRP roofing panels be installed on both residential and commercial verandas?

- FRP roofing panels are ideal for both residential and commercial verandas. These panels, made of Fiberglass Reinforced Plastic, offer versatility and can be utilized in different applications, such as verandas. They possess exceptional durability, resistance to weather conditions, and insulation properties, which make them suitable for both residential and commercial purposes. Moreover, FRP panels are lightweight and simple to install, making them a favored option for veranda roofs. Whether it is a residential or commercial veranda, installing FRP roofing panels can improve the appearance and functionality of the area, while providing enduring protection against the elements.

- Q: Do FRP roofing panels require a specific type of flashing?

- FRP roofing panels necessitate a particular kind of flashing to ensure their proper installation. Flashing is vital in any roofing system as it not only prevents water leaks but also diverts water away from vulnerable areas. In the case of FRP roofing panels, it is essential to use flashing that is compatible with the material and specifically designed for FRP roofs. When choosing flashing for FRP roofing panels, the material is a primary consideration. FRP panels are constructed from fiberglass reinforced plastic, a lightweight and durable substance. Consequently, the flashing used should also be lightweight and flexible to guarantee a snug fit and an effective seal. Another crucial factor to bear in mind is the design of the flashing. FRP roofing panels possess a unique profile, necessitating flashing that can accommodate their distinct shape and size. This may involve customized flashing or specialized flashing designed explicitly for FRP roofs. The flashing must be capable of covering the panels' edges and creating a watertight seal to prevent water from infiltrating beneath the panels and causing damage. To determine the specific type of flashing required for FRP roofing panels, it is always advisable to consult a professional roofing contractor or manufacturer. They possess the knowledge and expertise necessary to recommend the most suitable flashing option based on the specific characteristics of the FRP panels and the environmental conditions in which they will be installed. By utilizing the correct flashing, you can ensure the longevity and performance of your FRP roofing system.

- Q: What maintenance is required for FRP roofing panels?

- FRP (Fiber Reinforced Plastic) roofing panels are known for their durability and low maintenance requirements. However, there are a few key maintenance tasks that should be performed regularly to ensure the longevity and performance of FRP roofing panels. Firstly, it is important to regularly inspect the panels for any signs of damage, such as cracks, chips, or loose fasteners. Any such issues should be addressed promptly to prevent further damage and potential leaks. Additionally, it is recommended to clean the panels at least twice a year, or more frequently if they are exposed to heavy dirt, debris, or pollutants. To clean FRP roofing panels, a mild detergent or soap solution and a soft brush or sponge can be used. Avoid using abrasive materials or harsh chemicals, as they can damage the surface of the panels. It is also important to rinse the panels thoroughly with clean water after cleaning to remove any residue. Furthermore, it is advisable to trim any overhanging tree branches or vegetation near the panels to prevent them from scratching or damaging the surface. Regularly clearing off leaves, twigs, and other debris that may accumulate on the panels will also help maintain their integrity. Lastly, it is recommended to consult the manufacturer's guidelines for specific maintenance instructions and recommendations tailored to the particular FRP roofing panels being used. Following these guidelines will ensure that the panels remain in good condition and provide long-lasting protection for the building.

- Q: Are FRP roofing panels resistant to warping due to heat?

- Yes, FRP roofing panels are highly resistant to warping due to heat. The unique composition of fiberglass reinforced plastic (FRP) makes these panels highly durable and stable, allowing them to withstand high temperatures without warping.

- Q: Are FRP roofing panels resistant to chemical spills or leaks?

- Yes, FRP (fiberglass reinforced plastic) roofing panels are resistant to chemical spills or leaks. FRP panels are made of a combination of fiberglass and plastic materials, which provide excellent resistance to a wide range of chemicals. The panels are designed to be non-reactive and non-corrosive, making them highly resistant to the effects of chemical exposure. This resistance is particularly important in industrial or commercial settings where there is a higher likelihood of chemical spills or leaks occurring. FRP roofing panels have been tested and proven to withstand various chemicals, including acids, solvents, and oils, without deteriorating or sustaining damage. Therefore, they are a reliable choice for environments where chemical resistance is a primary concern.

Send your message to us

FRP Roofing Panel for Houses - Corrugated Metal Roof Sheet Manufacturing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords