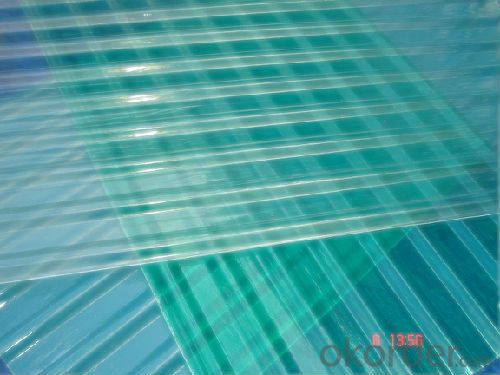

FRP Roofing Panel - Fiber Reinforcement Plastic Flat Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction of Fiber Reinforcement Plastic Flat Panel

The parts made via Hand Layer-up FRP(Fiberglass Reinforced Plastic) are created by applying liquid resin and fiberglass mat along with gel-coat onto an open-faced mould. The fiberglass mat will be laid into the moulds and the resin will be brushed into the fiberglass mat carefully according to the temperature and humidity situations. The semi-product after demoulded will be trimmed according to the drawings. Then the parts will be cleaned and polished to be packed.

Hand Layer-up parts are lighter and perform better on high strength-to-weight ratios. The parts made from hand layer-up FRP are with one side smooth-the gloss can be above 80. Now these parts are widely used on boat hulls, auto parts, truck and tractor covers, chemical retainers, heavy equipment panels, even rubbish cabins etc.

Applications of Fiber Reinforcement Plastic Flat Panel

1.Company building,industry building,public building,beautify the factory premises adopting the light.

2.Decorating the inside and outside of the modern business building.

3.Sound absorbtion wall for freeway,high-speed railway and sidings.

4.Subway exits,parking lots,garage tents,Bus stations,terminals,shopping arcades,large stadium and rain tents,pagodas,hallway tents.

5.Building ceiling of greenhouse

Advantage of Fiber Reinforcement Plastic Flat Panel

1. Corrosion resistance

products are resistant to the corrosion of gas and liquid of acids, alkalis, salt, and organic solvent so that they can avoid the problem of rusting steel and rotten wood.

2. Light weight and high intensity

fiberglass products are molded through the solidification of fiberglass and resin under high temperature. Its density is only one quarter of that of steel, and two-thirds of that of aluminum. But its intensity is ten times that of PVC, exceeding the aluminum products and reaching the level of common carbon steel. Due to its light weight, the products require less base support and possess the features of easy installation and low costs.

3. Inflaming Retarding

The common oxygen index of common fiberglass products is above 32 (according to GB8924). By design, the flame spreading index of the high inflaming retarding ethylene products is below 10, which meets the requirements of engineering fire resistance for safety.

4. Collision Resistance and Fatigue Resistance

fiberglass products can resist collision and keep the original shape after repeated bending so as to be used as spring.

5. Age Resistance

The normal longevity is more than 20 years. The research result shows that the intensity will still retain more than 85% after 20 years’ exposure to the atmosphere.

6.Good appearance and Easy Maintenance

The color slurry offiberglass products is mixed with resin to make the color bright and difficult to fade. No painting is needed on the surface which is clean after washing.

Main Specification of Fiber Reinforcement Plastic Flat Panel:

Item | Parameters |

Thickness | 0.8mm~4.0mm |

Width | <2.6m |

Length | 100m/roll & Pcs of special size |

FAQ:

1. Why Choose us?

CNBM is a stated owned company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

3. Can you provide sample?

Yes, we can offer free sample for you.

4. Payment terms?

We can accept L/C, T/T etc.

5. Do you offer OEM service?

Yes, we can print customers’ logo on the packaging;

And the size and specification can be produced and design according to your demand.

- Q: Can FRP roofing panels be used for storage sheds?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for storage sheds. FRP panels are lightweight, durable, and resistant to weathering, making them an excellent choice for outdoor structures like storage sheds. They provide excellent protection against UV rays, moisture, and temperature extremes, ensuring that the contents of the shed are well-protected. Additionally, FRP panels are easy to install and maintain, making them a cost-effective and practical roofing option for storage sheds.

- Q: Are FRP roofing panels easy to clean?

- Yes, FRP roofing panels are generally easy to clean. FRP stands for Fiberglass Reinforced Plastic, which is a durable and low-maintenance material. These panels have a smooth surface that resists the accumulation of dirt, dust, and other debris. Cleaning them usually involves simple steps such as rinsing with water and using a mild detergent if necessary. Additionally, FRP roofing panels are not prone to staining or discoloration, making them relatively hassle-free when it comes to maintenance. However, it is always recommended to follow the manufacturer's cleaning instructions for optimal results.

- Q: Can FRP roofing panels be installed on aluminum structures?

- Yes, FRP roofing panels can be installed on aluminum structures.

- Q: Can FRP roofing panels be used for outdoor structures?

- Yes, FRP roofing panels can be used for outdoor structures. FRP (Fiberglass Reinforced Plastic) roofing panels offer excellent durability, weather resistance, and UV protection, making them suitable for outdoor applications. They are commonly used for structures like patios, pergolas, gazebos, carports, and agricultural buildings. FRP panels provide a lightweight and low-maintenance roofing option that can withstand various climatic conditions.

- Q: Do FRP roofing panels have any specific warranty coverage?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels typically come with specific warranty coverage. The warranty coverage for FRP roofing panels may vary depending on the manufacturer and the specific product. However, most reputable manufacturers offer warranties that provide coverage against defects in materials or workmanship. The warranty coverage for FRP roofing panels often includes a specific duration, such as 10 years or 25 years, during which the manufacturer guarantees that the panels will remain structurally sound and free from defects. This means that if any issues arise with the panels during the warranty period, the manufacturer will either repair or replace the defective panels at no additional cost to the customer. It is important to note that warranty coverage may not include damage caused by improper installation, accidents, natural disasters, or normal wear and tear. Additionally, some manufacturers may offer extended warranties or additional coverage options for an added cost. To ensure that you fully understand the warranty coverage for a specific FRP roofing panel, it is recommended to carefully review the terms and conditions provided by the manufacturer. This will help you determine the specific coverage details, limitations, and any necessary steps to claim warranty benefits. Overall, FRP roofing panels typically come with specific warranty coverage that provides peace of mind to customers, protecting them against potential product defects and ensuring the longevity and performance of the panels.

- Q: Can FRP roofing panels be used for both residential and commercial applications?

- FRP roofing panels have a wide range of uses, catering to both residential and commercial needs. Their versatility and durability make them suitable for different types of buildings and structures. In residential settings, you will commonly find FRP panels utilized in patio covers, carports, and pergolas. In commercial spaces, they are frequently employed in warehouses, factories, and industrial buildings. The advantages of FRP roofing panels are manifold. They exhibit high strength, boast a lightweight design, provide resistance against corrosion and UV rays, and are easy to install. These qualities contribute to their widespread popularity in both residential and commercial projects.

- Q: Are FRP roofing panels suitable for industrial applications?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are suitable for industrial applications. They are highly durable, lightweight, and resistant to corrosion, making them ideal for industrial settings where there may be exposure to harsh chemicals, extreme temperatures, or heavy machinery. Additionally, FRP roofing panels offer excellent strength and insulation properties, providing protection and energy efficiency for industrial buildings.

- Q: Are FRP roofing panels resistant to oil or chemical spills?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are resistant to oil and chemical spills. The composition of FRP roofing panels includes a durable and non-permeable fiberglass layer, which acts as a barrier against various chemicals, including oil. This resistance helps prevent the penetration of oil or chemicals into the roofing material, ensuring that spills can be easily contained and cleaned without causing damage to the panels. Additionally, FRP roofing panels are often coated with a protective layer that enhances their resistance to chemical exposure and further improves their ability to withstand oil spills. Therefore, FRP roofing panels are an excellent choice for environments where oil or chemical spills may occur, such as industrial or commercial facilities.

- Q: Are FRP roofing panels compatible with rooftop gardens or green roof systems?

- Yes, FRP roofing panels are compatible with rooftop gardens or green roof systems. FRP stands for Fiber Reinforced Polymer, which is a lightweight and durable material that can withstand the weight of a green roof system. The panels provide excellent insulation and can be designed to have a high load-bearing capacity, making them suitable for supporting the additional weight of soil, plants, and water in a rooftop garden. Additionally, FRP panels are resistant to moisture, UV rays, and chemicals, which are important factors to consider when implementing a green roof system. Overall, FRP roofing panels are a great choice for integrating rooftop gardens or green roof systems onto buildings.

- Q: Can FRP roofing panels be used for both new construction and roof replacement projects?

- Yes, FRP roofing panels can be used for both new construction and roof replacement projects. FRP panels are versatile and can be easily installed on existing structures or integrated into new construction projects. Their lightweight nature, durability, and resistance to corrosion make them an excellent choice for various roofing applications.

Send your message to us

FRP Roofing Panel - Fiber Reinforcement Plastic Flat Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords