FRP Pultrusion Profiles - Corrosion Resistant and Fire Resistant FRP Grating

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 5000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

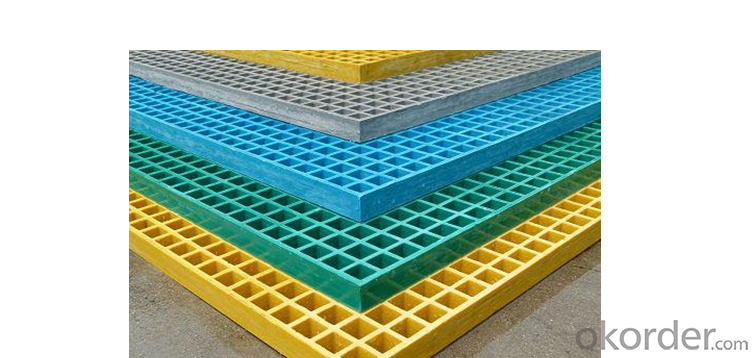

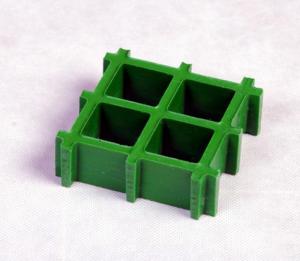

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

Corrosion Resistance

Fire Resistance

Light Weight & High Strength

Safety & Anti-slip

Electrical Insulating

Aging Resistance

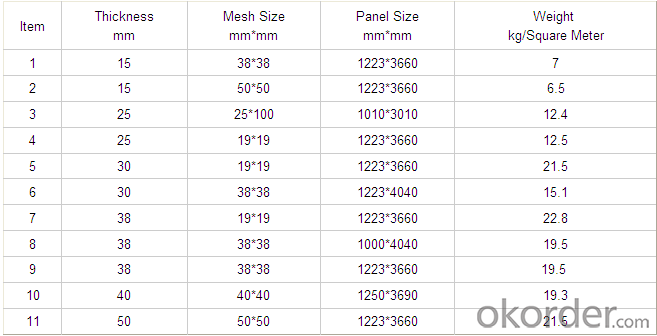

Specification

Advantage

coated with prevent aging layer

excellent insulating performance

no maintenance

high strength

long service life

easy installation

Application

Power plants, substation equipment enclosures, antimagnetic, anti-static,to prevent small animals into the equipment failure, as there is electricity facilities and without power interval intervals.

In high voltage electrical equipment for power line work, in order to prevent workers go wrong location, charged interval or near electrically charged equipment to dangerous distance.

Pool railings in sewage treatment industry

Corrosive chemical industry equipment around the fence

All kinds of building maintenance section

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. How's the payment?

Telegraphic Transfer(T/T) or Letter of Credit(L/C)

3. How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

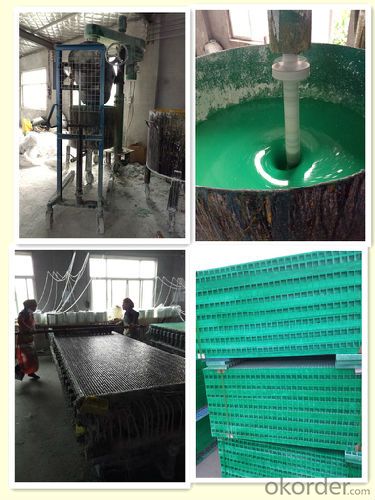

FACTORY

- Q: Are FRP pultrusion profiles resistant to alkaline substances?

- Yes, FRP pultrusion profiles are generally resistant to alkaline substances. The use of fiberglass reinforced polymer (FRP) in pultruded profiles provides excellent resistance to a wide range of chemicals, including alkaline substances. The resin used in the manufacturing process is typically a thermosetting polymer, such as polyester or vinyl ester, which offers high resistance to alkaline solutions. Moreover, the reinforcement of fiberglass imparts additional strength and durability to the profiles, making them highly resistant to corrosion and degradation from alkaline substances. However, it is important to note that the specific resistance of FRP pultrusion profiles to alkaline substances may vary depending on the specific resin formulation and manufacturing process. Therefore, it is recommended to consult with the manufacturer or supplier to ensure the profiles meet the desired resistance requirements for specific alkaline environments.

- Q: What are the different shapes and sizes of FRP pultrusion profiles available?

- There is a wide selection of FRP pultrusion profiles, which come in various shapes and sizes, to accommodate different applications and industries. Some of the commonly found shapes are as follows: 1. Square and rectangular profiles: These profiles are utilized in construction, infrastructure, and industrial sectors, and they come in different dimensions. They possess exceptional structural strength and can serve as beams, columns, or other load-bearing components. 2. Round profiles: Round FRP pultrusion profiles are frequently employed as structural supports, handrails, and guardrails. They are available in different diameters to suit specific requirements. 3. I-beams: FRP I-beams are well-liked in the construction field because of their high strength-to-weight ratio. They are commonly used as structural members, supporting elements, or floor joists. 4. Channel profiles: Channel-shaped FRP profiles are utilized in applications that demand a combination of strength and versatility. They find use in cable trays, equipment supports, and framing systems. 5. Angle profiles: FRP angle profiles are commonly used as reinforcements or supports in construction and industrial settings. They provide stability and structural integrity to various components. 6. Custom profiles: In addition to the standard shapes mentioned above, FRP pultrusion profiles can be tailor-made to meet specific requirements. Manufacturers have the capability to create profiles with unique shapes and sizes that cater to the needs of different applications. It is worth noting that the availability of shapes and sizes may differ among manufacturers. Therefore, it is advisable to consult suppliers or manufacturers to determine the specific range of FRP pultrusion profiles they offer.

- Q: How do FRP pultrusion profiles perform in high-vibration applications?

- High-vibration applications are where FRP (Fiber Reinforced Polymer) pultrusion profiles truly excel. The exceptional properties of FRP materials make them an ideal choice for these situations. To begin with, FRP pultrusion profiles are renowned for their impressive strength-to-weight ratio. Unlike traditional materials like steel or aluminum, FRP profiles are significantly lighter while still possessing remarkable strength and rigidity. This lightweight quality reduces the overall mass of the structure, resulting in lower vibration amplitudes. Furthermore, FRP materials boast outstanding damping characteristics. Damping refers to a material's ability to dissipate energy and decrease vibration amplitudes. In comparison to other materials, FRP pultrusion profiles have a higher damping coefficient, meaning they can more effectively absorb and dissipate vibrations. This minimizes the transmission of vibrations throughout the structure, reducing the risk of resonance and fatigue failure. In addition, FRP pultrusion profiles demonstrate exceptional resistance to fatigue and corrosion. Vibrations can cause cyclic loading, which can lead to fatigue failure over time. However, the inherent properties of FRP materials, including their excellent tensile strength and resistance to environmental factors, make them highly resilient to fatigue and corrosion. This guarantees the longevity and durability of the profiles, even in high-vibration environments. Moreover, FRP pultrusion profiles offer immense design flexibility, allowing for customized shapes and sizes that can be tailored to specific applications. This flexibility allows engineers to optimize the profiles' performance in high-vibration scenarios by adjusting the geometry and composition to enhance their dynamic characteristics. In summary, FRP pultrusion profiles are exceptionally suited for high-vibration applications due to their lightweight nature, excellent damping characteristics, resistance to fatigue and corrosion, and design flexibility. These profiles provide a reliable and durable solution that can effectively withstand the challenges posed by vibrations, ensuring safe and efficient operation in such environments.

- Q: Can FRP pultrusion profiles be customized according to specific requirements?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be customized according to specific requirements. Pultrusion is a manufacturing process that involves pulling continuous fibers through a liquid resin bath, then through a heated die to cure the resin and form the desired shape. This process allows for great flexibility in design and customization. The customization options for FRP pultrusion profiles include various dimensions, shapes, colors, and surface finishes. The dimensions can be tailored to meet specific length, width, and thickness requirements. The shapes can range from basic geometries like rectangular or round profiles to more complex designs with custom cross-sections. In terms of color, FRP pultrusion profiles can be pigmented during the manufacturing process to achieve the desired color or can be painted or coated afterwards. This allows for matching specific color requirements or ensuring compatibility with existing structures or products. Furthermore, surface finishes can be customized to achieve desired properties such as increased slip resistance, UV resistance, or fire resistance. Surface treatments like sanding, coating, or adding special additives can be applied to meet specific performance requirements. Overall, FRP pultrusion profiles offer a high level of customization to meet specific project or application needs. They are versatile, lightweight, corrosion-resistant, and have excellent strength-to-weight ratios, making them suitable for various industries such as construction, transportation, infrastructure, and aerospace.

- Q: Are FRP pultrusion profiles resistant to electrical arcing?

- Generally, FRP pultrusion profiles exhibit resistance to electrical arcing due to their composition of non-conductive materials such as fiberglass reinforced plastic. By not conducting electricity, these profiles prove to be an optimal choice when concerns arise regarding electrical arcing and conductivity. Nevertheless, it is crucial to acknowledge that the extent of their resistance to electrical arcing may differ based on the unique composition and design of the FRP pultrusion profiles. Therefore, it is advisable to consult the manufacturer or supplier of the profiles to ensure they meet the specific electrical resistance standards required for a given application.

- Q: Can FRP pultrusion profiles be used in architectural or decorative applications?

- Yes, FRP pultrusion profiles can be used in architectural or decorative applications. They offer various advantages such as high strength-to-weight ratio, resistance to corrosion and UV radiation, and design flexibility. Additionally, FRP pultrusion profiles can be customized to match specific aesthetic requirements, making them suitable for architectural and decorative purposes.

- Q: How do FRP pultrusion profiles perform in high-wind areas?

- Due to their exceptional performance characteristics, FRP pultrusion profiles are highly suitable for use in high-wind areas. These profiles utilize a combination of continuous glass fibers and a polymer resin matrix, resulting in a material that is both lightweight and incredibly strong and durable. One major advantage of FRP pultrusion profiles in high-wind areas is their excellent resistance to corrosion. Unlike traditional materials like steel or wood, FRP does not rust or rot when exposed to moisture or harsh weather conditions. This makes them ideal for regions prone to hurricanes or coastal environments where wind-driven saltwater or heavy rain can cause accelerated deterioration in other materials. In addition, FRP pultrusion profiles have a high strength-to-weight ratio, allowing them to withstand high wind loads without adding excessive weight to structures. Their lightweight nature makes transportation and installation easy, reducing overall costs and construction time in high-wind areas. Furthermore, FRP pultrusion profiles exhibit excellent dimensional stability, meaning they resist warping or deforming under extreme wind pressures. This stability ensures that structures utilizing FRP profiles maintain their integrity and functionality even in the face of strong winds. Moreover, FRP pultrusion profiles can be customized to meet specific wind load requirements. They can be engineered to have specific flexural or tensile strengths, allowing for tailored solutions to suit the demands of high-wind areas. Overall, FRP pultrusion profiles are an excellent choice for structures in high-wind areas due to their corrosion resistance, high strength-to-weight ratio, dimensional stability, and customization capabilities. These profiles provide a reliable, long-lasting, and cost-effective solution for structures exposed to intense wind loads, ensuring the safety and durability of the built environment.

- Q: Can FRP pultrusion profiles be used in water treatment plants?

- Indeed, water treatment plants can utilize FRP (Fiber Reinforced Polymer) pultrusion profiles. The utilization of FRP pultrusion profiles in this industry brings forth numerous advantages that render them highly suitable. To begin with, FRP pultrusion profiles possess exceptional resistance to corrosion. Given the aggressive environments found in water treatment plants, where exposure to chemicals and moisture is common, the traditional materials like steel are prone to corrosion and degradation. However, FRP pultrusion profiles are immune to corrosion, making them an ideal choice for water treatment applications. Moreover, FRP pultrusion profiles exhibit remarkable strength-to-weight ratios. This implies that they offer superior structural integrity while being lightweight, rendering them easier to handle and install within water treatment plants. Additionally, their high strength enables them to endure the loads and pressures typically encountered in these environments. Furthermore, FRP pultrusion profiles are non-conductive of electricity. This feature is particularly advantageous within water treatment plants where there may be a necessity to isolate electrical equipment or components to prevent short circuits and safeguard personnel. FRP profiles provide a safe and dependable solution in such cases. Lastly, FRP pultrusion profiles possess a long service life and necessitate minimal maintenance. They do not rot, rust, or corrode, ensuring durability and longevity even in harsh water treatment conditions. This reduces downtime and maintenance costs, making FRP profiles a cost-effective choice for water treatment plant applications. All in all, due to their corrosion resistance, high strength-to-weight ratio, electrical non-conductivity, and long service life, FRP pultrusion profiles are an exceptional option for utilization in water treatment plants. Their usage can contribute to enhanced efficiency, reduced maintenance, and increased durability in water treatment processes.

- Q: Are FRP pultrusion profiles resistant to weathering?

- Yes, FRP pultrusion profiles are highly resistant to weathering. The combination of fiberglass reinforcement and resin matrix used in pultrusion manufacturing provides excellent resistance to UV radiation, moisture, temperature variations, and other environmental factors, making them highly durable and long-lasting even in harsh weather conditions.

- Q: Can FRP pultrusion profiles be used in the construction and building materials industry?

- FRP pultrusion profiles are indeed applicable in the construction and building materials sector. These profiles are created by pulling continuous fibers through a resin bath and then into a heated die, which aids in curing the resin and shaping the profile. One of the primary advantages of FRP pultrusion profiles lies in their exceptional strength-to-weight ratio. Despite being lightweight, they possess incredible durability and strength, making them an optimal choice for construction purposes where weight reduction is desired. Moreover, FRP pultrusion profiles exhibit outstanding resistance to corrosion, which proves particularly advantageous in environments with moisture, chemicals, or harsh weather conditions. This corrosion resistance extends the lifespan of building materials, thereby reducing maintenance and replacement expenses. FRP pultrusion profiles can serve a wide array of construction applications, including structural components like beams, columns, and trusses. They are also frequently utilized as reinforcements in concrete structures, offering added strength and durability. Additionally, these profiles find utility in cladding, decking, handrails, ladders, and other non-structural elements within buildings. Furthermore, FRP pultrusion profiles provide design flexibility as they can easily be customized and manufactured to specific shapes, sizes, and properties. This adaptability renders them suitable for diverse construction projects, ranging from small-scale residential buildings to large-scale industrial complexes. In conclusion, FRP pultrusion profiles are highly appropriate for the construction and building materials industry due to their superior strength-to-weight ratio, corrosion resistance, design flexibility, and versatility.

Send your message to us

FRP Pultrusion Profiles - Corrosion Resistant and Fire Resistant FRP Grating

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 5000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords