FRP Pultrusion Profiles:Anti-Corrosion and Anti-Rust FRP Pultruded Grating

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

Pultruded grating is made by a par ticular assembly process, which using “I” shape as its main load-bearing and special rod to go through the bearing bar. Pultruded grating include the standard grating and the custom grating, the custom grating can be designed to meet customer’s requirement or special using condition by changing the shape, size and space of the bearing bars, the sur face can be covered with lozenge panel, grit panel, or added the anti-slippery sand directly.

FRP pultruded grating has the most characteristics of molded grating, but it has its distinct advantages, it has very high fiberglass content in the loading direction, so it has very high load capability, it has more superiority when used at wide span, so that the basic support will be decreased and the project cost will be reduced accordingly.

1.SPECIFICATION

The standard space between two crossbars is 6 inch or 12 inch.

Thickness (mm) | Bar width (mm) | Open space (mm) | Open rate (%) | Approx weight (kg/m |

25.4 | 15.2 | 22.8 | 60 | 13.2 |

25.4 | 15.2 | 15.2 | 50 | 15.9 |

25.4 | 15.2 | 10.1 | 40 | 18.5 |

25.4 | 40 | 10.8 | 21 | 14.5 |

38.1 | 15.2 | 22.8 | 60 | 15.8 |

38.1 | 15.2 | 15.2 | 50 | 19.1 |

38.1 | 15.2 | 10.1 | 40 | 22.4 |

50.8 | 25.4 | 25.4 | 50 | 16.6 |

50.8 | 25.4 | 12.7 | 33 | 21.1 |

2.CHOICE FOR PULTRUDED GRATING

Resin: GP resin, ISO resin,VE resin,Phenolic resin

Color choice: Yellow, gray, green, custom color

Surface choice: Groove surface, grit surface, lozenge cover surface

3.FEATURES

a. Anti-corrosion and anti-rust

b. Light weight and high strength

c. Anti-flammable

d. Anti- fatigue

e. Safe and anti-slippery

f. Anti-ageing

g. Easy of maintenance

h. Excellent electromagnetism property

i. Good economic benefit

4.FIELDS SERVED

Sewage treatment,

water supply and drainage,

chemical industry,

oil industry,

power engineering,

pulp and paper,

construction engineering,

spinning, marine engineering.

COMPANT DESCRIPTION

CNBM,China National Building Materials Group is a state-owned enterprise in charge of administrative affairs in china building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of 25 billion RMB and a total staff of 30,000.CNBM now owns 200 subordinating firms of solely owned and joint-venture companies.

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products,professional service and complete solution to our customers. Strong delivery capacity, advanced technology& management, strong financing capability and excellent after-sale service are our advantages in sharing international market.

PACKAGING & DELIVERY

1.PACKAGING DETAILS:

standard packing or your requirement

2.DELIVERY DETAIL:

Shipped in 30 days after payment

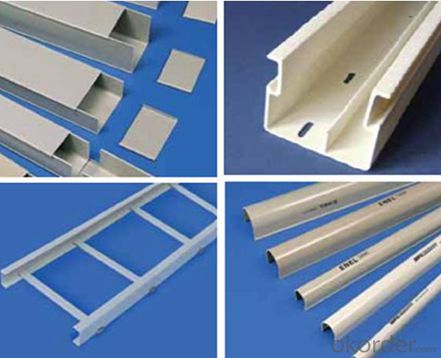

PICTURES

- Q: Can FRP pultrusion profiles be used in the aerospace industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the aerospace industry. These profiles offer numerous advantages such as high strength-to-weight ratio, corrosion resistance, and design flexibility. They can be used in various aerospace applications including structural components, interior parts, and electrical systems. Additionally, their non-conductive properties make them suitable for applications where electrical insulation is required.

- Q: What does M23 grade of glass fiber reinforced plastic section mean?

- There are many kinds of FRP Pultruded Shapes, such as glass fiber reinforced plastic round tube, glass fiber reinforced plastic square tube, glass fiber reinforced plastic rectangular tube, glass fiber reinforced plastic round bar, glass fiber reinforced plastic i-beam.

- Q: Are FRP pultrusion profiles resistant to impact from heavy machinery?

- FRP pultrusion profiles are generally known for their high strength-to-weight ratio and excellent mechanical properties, which make them resistant to various external impacts. However, the specific resistance to impact from heavy machinery depends on several factors. Firstly, the design and composition of the FRP pultrusion profiles play a vital role in determining their impact resistance. Different manufacturers may use various reinforcement materials, such as fiberglass, carbon fiber, or other composites, which can significantly affect the profiles' ability to withstand heavy machinery impacts. Additionally, the thickness and overall dimensions of the FRP profiles contribute to their impact resistance. Thicker profiles tend to provide higher resistance to impact loads compared to thinner ones. Moreover, profiles with reinforced sections or additional layers for structural integrity can further enhance their impact resistance. It is also essential to consider the specific application and the magnitude of impact expected from heavy machinery. While FRP pultrusion profiles can generally withstand moderate to high impacts, extreme forces or heavy machinery with substantial weight may still cause damage. In such cases, additional protective measures like using impact-resistant coatings or reinforcing the profiles with metal inserts may be necessary. Overall, FRP pultrusion profiles exhibit good resistance to impact from heavy machinery due to their inherent strength and durability. However, it is always recommended to consult with the manufacturer or a structural engineer to ensure the profiles meet the specific requirements of the application and machinery involved.

- Q: Are FRP pultrusion profiles resistant to saltwater corrosion?

- Indeed, FRP pultrusion profiles exhibit exceptional resistance to saltwater corrosion. Their corrosion resistance is a significant advantage over traditional materials like steel or aluminum. The combination of reinforcing fibers and resin matrix in FRP profiles endows them with inherent resistance to the corrosive effects of saltwater. FRP profiles consist of a blend of glass or carbon fibers that are embedded in a thermosetting resin. These constituents do not chemically react with saltwater, effectively preventing the corrosion commonly observed in metals exposed to saltwater for prolonged periods. Additionally, the resin matrix utilized in FRP profiles acts as a protective barrier, further impeding saltwater from reaching the reinforcing fibers. The corrosion resistance of FRP pultrusion profiles renders them exceptionally suitable for applications in marine settings. Seawalls, dock fenders, offshore platforms, and marine vessels frequently employ FRP profiles due to their durability in saltwater environments. This durability guarantees long-term performance and minimizes the necessity for frequent maintenance or replacement. However, it is crucial to acknowledge that although FRP pultrusion profiles demonstrate high resistance to saltwater corrosion, they can still be influenced by other factors like UV radiation or chemical exposure. Consequently, it is vital to consider the precise environmental conditions and consult manufacturers or experts to select the most appropriate FRP profile for a given application.

- Q: Are FRP pultrusion profiles resistant to oil and grease?

- FRP (Fiber Reinforced Plastic) pultrusion profiles are generally known for their excellent resistance to oil and grease. The combination of fibers, typically glass or carbon, with a polymer resin matrix results in a material that is inherently resistant to many chemicals, including oil and grease. This resistance is attributed to the non-reactive nature of the polymer resin, which prevents the oil or grease from penetrating the material and causing damage. Additionally, the pultrusion manufacturing process used to produce FRP profiles further enhances their resistance to oil and grease. During the pultrusion process, the fibers are impregnated with the resin and then pulled through a heated die, where the resin is cured. This creates a strong, uniform material with a dense surface that is less porous and more resistant to chemical penetration. It is important to note that the specific resistance of FRP pultrusion profiles to oil and grease can vary depending on the type of resin used and the specific application conditions. In some cases, specialized resin formulations can be used to further enhance the oil and grease resistance of FRP profiles, ensuring suitability for even more demanding environments. Overall, FRP pultrusion profiles are generally considered to be highly resistant to oil and grease, making them an excellent choice for applications where exposure to these substances is expected. However, it is always recommended to consult with the manufacturer or supplier to ensure that the specific FRP profile being used is appropriate for the intended application and chemical exposure.

- Q: Are FRP pultrusion profiles resistant to fading or discoloration?

- FRP pultrusion profiles possess exceptional resistance against fading and discoloration. This attribute stems from the inherent properties of the materials employed in their construction. Typically, FRP profiles are fabricated using a blend of fiberglass reinforcements and a polymer resin matrix, both of which inherently resist UV radiation and other environmental factors that lead to fading and discoloration. The polymer resin matrix used in FRP profiles is specifically designed to exhibit outstanding chemical resistance and UV stability. As a result, the profiles retain their original color and appearance for an extended duration. This makes FRP pultrusion profiles an ideal choice for outdoor applications, where exposure to sunlight and harsh weather conditions is prevalent. Additionally, the pultrusion manufacturing process ensures that the color of FRP profiles remains consistent throughout their entire cross-section. Consequently, even in the presence of minor surface damage or wear, the underlying color of the profile remains unchanged, ensuring a uniform appearance. In summary, FRP pultrusion profiles offer unparalleled resistance against fading and discoloration, making them a resilient and long-lasting option for a wide range of applications, including construction, infrastructure, transportation, and more.

- Q: Are FRP pultrusion profiles resistant to chemicals used in mining operations?

- FRP pultrusion profiles, commonly referred to as Fiber Reinforced Polymer, generally exhibit resistance to chemicals commonly used in mining operations. These profiles are well-known for their exceptional chemical resistance properties, making them suitable for a variety of corrosive environments, including mining operations. To provide resistance against the vast array of chemicals typically found in mining applications, such as acids, alkalis, solvents, and corrosive gases, the resin matrix used in FRP pultrusion profiles can be carefully selected. Additionally, the reinforcement fibers, often composed of glass or carbon, further enhance the overall chemical resistance of the profile. Moreover, FRP pultrusion profiles are non-conductive, making them an ideal choice for both electrical and mining applications. They are not susceptible to corrosion or degradation when exposed to chemicals, ensuring their durability and longevity in harsh mining environments. However, it is crucial to consider the specific chemicals and concentrations used in mining operations. Although FRP pultrusion profiles generally possess excellent chemical resistance, prolonged exposure to highly aggressive chemicals or high concentrations may necessitate additional measures. These measures could include selecting specific resin systems or applying surface coatings to ensure optimal performance and longevity. To determine the most suitable materials for specific mining chemical environments, it is advisable to consult with FRP manufacturers or experts.

- Q: Are FRP pultrusion profiles resistant to hail or impact damage?

- FRP pultrusion profiles exhibit exceptional resistance to both hail and impact damage. The incorporation of reinforcing fibers such as carbon or glass, along with a polymer resin matrix, grants these profiles unparalleled strength and durability. When compared to materials like wood, steel, or aluminum, FRP pultrusions offer significantly superior impact resistance. These profiles are specifically engineered to endure even the harshest environmental conditions, including hailstorms. The composite composition of FRP enables it to effectively absorb and distribute the energy generated by impacts, effectively preventing the formation of cracks or fractures. As a result, they are an ideal choice for various applications that necessitate protection against hail or impact damage, such as building facades, bridges, handrails, and utility poles. Moreover, FRP pultrusion profiles possess an impressive strength-to-weight ratio, meaning they can withstand heavy impacts without undermining their structural integrity. Furthermore, they are non-corrosive, making them impervious to rust or degradation caused by hail or impact. To summarize, the composite construction and exceptional strength-to-weight ratio of FRP pultrusion profiles render them highly resistant to hail or impact damage. They offer a reliable and long-lasting solution for applications that demand durability and resilience in the face of harsh environmental conditions.

- Q: Can FRP pultrusion profiles be used in the construction of pedestrian bridges?

- Yes, FRP pultrusion profiles can be used in the construction of pedestrian bridges. FRP pultrusion profiles offer several advantages such as high strength, corrosion resistance, low maintenance, and lightweight properties, making them suitable for pedestrian bridge applications. Additionally, the flexibility in design and customization options of FRP pultrusion profiles allows for efficient construction and installation of pedestrian bridges.

- Q: Are FRP pultrusion profiles resistant to fuels?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to fuels. The combination of high-strength fibers and a polymer matrix makes FRP profiles highly resistant to various chemicals, including fuels. This resistance is primarily due to the non-reactive nature of the polymer matrix, which prevents the fuel from causing any significant degradation or damage to the profiles. FRP pultrusion profiles are commonly used in industries where exposure to fuels is a common occurrence, such as the automotive, aerospace, and oil and gas sectors. These profiles have been extensively tested and proven to withstand prolonged contact with fuels without experiencing any detrimental effects. Additionally, FRP profiles offer several advantages over traditional materials like steel or aluminum in fuel-related applications. They are corrosion-resistant, lightweight, and have excellent dimensional stability, making them ideal for use in environments where the risk of fuel exposure is high. However, it is important to note that the specific resistance of FRP pultrusion profiles to fuels may vary depending on the type and concentration of the fuel, as well as the specific composition of the FRP material. Therefore, it is always recommended to consult with the manufacturer or supplier to ensure that the chosen FRP profiles are suitable for the specific fuel-related application.

Send your message to us

FRP Pultrusion Profiles:Anti-Corrosion and Anti-Rust FRP Pultruded Grating

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords