FRP Pultrusion Profiles - Anti-Corrosion, Anti-Rust, High-Quality FRP Pultruded Grating

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

Pultruded grating is made by a particular assembly process, which using “I” shape as its main load-bearing and special rod to go through the bearing bar. Pultruded grating include the standard grating and the custom grating, the custom grating can be designed to meet customer’s requirement or special using condition by changing the shape, size and space of the bearing bars, the surface can be covered with lozenge panel, grit panel, or added the anti-slippery sand directly.

FRP pultruded grating has the most characteristics of molded grating, but it has its distinct advantages, it has very high fiberglass content in the loading direction, so it has very high load capability, it has more superiority when used at wide span, so that the basic support will be decreased and the project cost will be reduced accordingly.

SPECIFICATION

Thickness (mm) | Bar width (mm) | Open space (mm) | Open rate (%) | Approx weight (kg/m |

25.4 | 15.2 | 22.8 | 60 | 13.2 |

25.4 | 15.2 | 15.2 | 50 | 15.9 |

25.4 | 15.2 | 10.1 | 40 | 18.5 |

25.4 | 40 | 10.8 | 21 | 14.5 |

38.1 | 15.2 | 22.8 | 60 | 15.8 |

38.1 | 15.2 | 15.2 | 50 | 19.1 |

38.1 | 15.2 | 10.1 | 40 | 22.4 |

50.8 | 25.4 | 25.4 | 50 | 16.6 |

50.8 | 25.4 | 12.7 | 33 | 21.1 |

CHOICE FOR PULTRUDED GRATING

Resin: GP resin, ISO resin, VE resin, Phenol resin

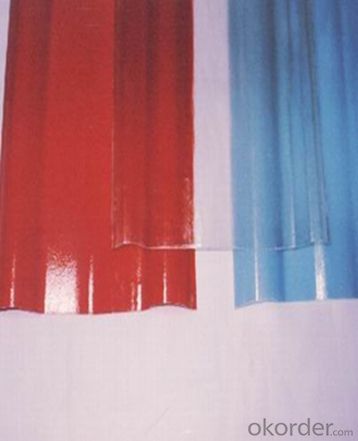

Color choice: Yellow, gray, green, custom color

Surface choice: Groove surface, grit surface, lozenge cover surface

FEATURES

a. Anti-corrosion and anti-rust

b. Light weight and high strength

c. Anti-flammable

d. Anti- fatigue

e. Safe and anti-slippery

f. Anti-ageing

g. Easy of maintenance

h. Excellent electromagnetism property

i. Good economic benefit

FIELDS SERVED

Sewage treatment,

water supply and drainage,

chemical industry,

oil industry,

power engineering,

pulp and paper,

construction engineering,

spinning, marine engineering.

APPLICATION

Operation terrace,

stair walkway,

ground floor,

trench cover,

sidewalk,

foot bridge,

equipment safety fence,

scaffold.

COMPANT DESCRIPTION

CNBM,China National Building Materials Group is a state-owned enterprise in charge of administrative affairs in china building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of 25 billion RMB and a total staff of 30,000.CNBM now owns 200 subordinating firms of solely owned and joint-venture companies.

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products,professional service and complete solution to our customers. Strong delivery capacity, advanced technology& management, strong financing capability and excellent after-sale service are our advantages in sharing international market.

FAQ

1.Q:Are you factory or trading company ?

A:We are Factory produce FRP machines and FRP products.

2.Q:If can customized by customers requirements?

A:yes,we can produce the machine with customized size.

3.Q:How about the payment?

A:We accept any kind of payment.

4.Q:What is the guarantee?

A:Gurantee is one year.

5.Q:If you can training?

A:yes ,we can training in our factory also can send engineers to your factory training.

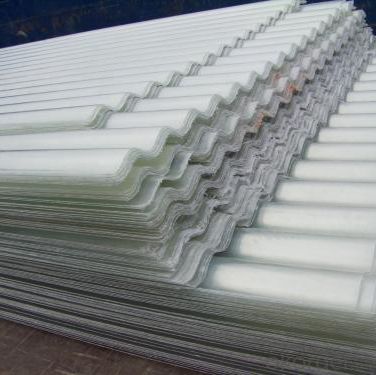

PICTURES

- Q: What are the typical applications for FRP pultrusion profiles?

- Some typical applications for FRP pultrusion profiles include structural components in the construction industry, such as beams, columns, and reinforcements. They are also used in the transportation industry for manufacturing lightweight and corrosion-resistant parts for vehicles and ships. Additionally, FRP pultrusion profiles find applications in electrical and power generation industries, as well as in the manufacturing of sports equipment and infrastructure.

- Q: Are FRP pultrusion profiles resistant to vibration or shock?

- Yes, FRP pultrusion profiles are generally resistant to both vibration and shock due to their high strength-to-weight ratio and excellent damping properties. The composite materials used in their construction, such as fiberglass and resin, offer excellent resistance to vibrations and mechanical shocks, making them ideal for applications where such conditions are present.

- Q: Are FRP pultrusion profiles resistant to chemicals used in pharmaceutical manufacturing?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles are highly resistant to chemicals used in pharmaceutical manufacturing. FRP profiles are made by impregnating fibers with a resin matrix, typically polyester or vinyl ester, which provides excellent chemical resistance. These profiles are designed to withstand exposure to a wide range of chemicals including acids, alkalis, solvents, and various cleaning agents commonly used in pharmaceutical manufacturing processes. The combination of the fiber reinforcement and the chemical-resistant resin matrix makes FRP pultrusion profiles an ideal choice for applications where exposure to aggressive chemicals is a concern. Unlike traditional materials like steel or wood, FRP profiles do not corrode or react chemically with the substances they come into contact with. Furthermore, FRP pultrusion profiles offer several other advantages for pharmaceutical manufacturing applications. They have exceptional strength-to-weight ratio, are non-conductive, and have high mechanical resistance. Additionally, FRP is a non-porous material, preventing the absorption or release of chemicals, which is crucial for maintaining strict hygiene and avoiding contamination in pharmaceutical processes. Overall, FRP pultrusion profiles are a reliable and durable choice for pharmaceutical manufacturing environments, providing excellent resistance to the chemicals commonly used in these processes.

- Q: Can FRP pultrusion profiles be used in renewable energy projects?

- Certainly, FRP pultrusion profiles are capable of being used in renewable energy projects. They possess a wide range of advantages that make them suitable for various applications within the renewable energy sector. To begin with, FRP pultrusion profiles are both lightweight and strong, which makes them ideal for utilization in wind turbine blades. The lightweight nature of FRP materials allows for increased efficiency in wind energy generation by reducing the load on the turbine, thus enhancing overall performance. Furthermore, the high strength-to-weight ratio of FRP profiles ensures durability and longevity, even in severe environmental conditions. Additionally, FRP pultrusion profiles display exceptional resistance to corrosion, which renders them suitable for employment in solar panel mounting structures and other components exposed to moisture and outdoor elements. This corrosion resistance ensures that FRP profiles maintain their structural integrity and performance over an extended period, diminishing the need for frequent maintenance and replacement. Furthermore, FRP pultrusion profiles can be customized to meet specific project requirements, providing flexibility in design and functionality. They can be easily molded into complex shapes and sizes, facilitating the creation of innovative and efficient solutions for renewable energy projects. Moreover, FRP materials are non-conductive and possess excellent electrical insulation properties, making them suitable for use in electrical enclosures and support structures for renewable energy systems such as solar power plants. In conclusion, FRP pultrusion profiles can be effectively utilized in renewable energy projects due to their lightweight, strong, corrosion-resistant, customizable, and electrically-insulating properties. These characteristics make FRP profiles a reliable and sustainable choice for various applications within the renewable energy sector.

- Q: What is the compression strength of FRP pultrusion profiles?

- The compression strength of FRP pultrusion profiles can vary depending on the specific design and manufacturing process. However, on average, FRP pultrusion profiles typically exhibit compression strengths ranging from 20,000 to 40,000 pounds per square inch (psi).

- Q: Are FRP pultrusion profiles fire resistant?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are fire resistant. The combination of the reinforcing fibers and the polymer matrix used in FRP pultrusion profiles provide them with excellent fire resistance properties. These profiles are manufactured using a process known as pultrusion, which involves impregnating reinforcing fibers such as fiberglass or carbon fiber with a thermosetting resin. This resin undergoes a curing process, resulting in a strong and durable composite material. One of the key advantages of FRP pultrusion profiles is their inherent fire resistance. The thermosetting resin used in the manufacturing process has properties that make it highly resistant to fire. When exposed to flames or high temperatures, the resin does not melt or burn easily, thus preventing the spread of fire. Additionally, the reinforcing fibers in FRP profiles also contribute to their fire resistance. Fiberglass, for example, is an inorganic material that does not burn. It acts as a barrier against heat transfer and helps to minimize the spread of flames. Furthermore, FRP pultrusion profiles can be engineered to meet specific fire safety standards and regulations. By incorporating additional fire retardant additives or using specialized resin systems, the fire resistance of these profiles can be further enhanced. It is important to note that while FRP pultrusion profiles are fire resistant, their exact fire rating may vary depending on the specific composition and design. Therefore, it is essential to consult with manufacturers or suppliers who can provide detailed information about the fire resistance properties of their FRP pultrusion profiles.

- Q: How do FRP pultrusion profiles perform in high-traffic areas?

- Due to their outstanding performance characteristics, FRP pultrusion profiles are a top-notch selection for high-traffic areas. Crafted from reinforced fiberglass and resin, these profiles create an incredibly sturdy material that can endure heavy loads and continuous foot traffic. The high strength-to-weight ratio of FRP pultrusion profiles is one of their key advantages. This unique feature enables them to be lightweight while remaining remarkably strong, allowing them to bear heavy loads without compromising their structural integrity. Moreover, their non-corrosive nature makes them perfect for areas with high foot traffic, where exposure to moisture, chemicals, and other corrosive elements is prevalent. Not only do FRP pultrusion profiles possess exceptional resistance to wear and abrasion, but they also maintain their original appearance and functionality for an extended period, even in high-traffic areas where conventional materials quickly deteriorate due to constant footfalls and movement. Furthermore, these profiles exhibit remarkable resistance to UV radiation, ensuring that they do not degrade or fade when exposed to sunlight. This is especially crucial for high-traffic areas situated outdoors or with substantial windows, as the profiles will retain their strength and aesthetics even with constant exposure to the sun. Regarding maintenance, FRP pultrusion profiles require minimal upkeep. Their color and finish are inherent in the material itself, eliminating the need for regular painting or sealing. This significantly reduces maintenance costs and efforts, making them a cost-effective choice for high-traffic areas. In conclusion, FRP pultrusion profiles offer exceptional strength, durability, resistance to wear and abrasion, non-corrosive properties, UV resistance, and low maintenance requirements. Their ability to withstand heavy loads and continuous foot traffic guarantees long-lasting performance, making them a dependable choice for any high-traffic environment.

- Q: FRP pultrusion process?

- Reinforcement materials used in pultrusion processes, mainly glass fibers and their products, such as roving, continuous fiber felt, etc.. In order to meet the special requirements of the products, aramid fiber, carbon fiber and metal fiber can be used. No matter which fiber is used in the pultrusion process, the surface must be treated so that it can be well bonded with the resin matrix.

- Q: What types of materials are commonly used in FRP pultrusion?

- Commonly used materials in FRP pultrusion include fiberglass, polyester resin, vinyl ester resin, epoxy resin, carbon fiber, and aramid fiber.

- Q: What are the different surface finishes available for FRP pultrusion profiles?

- Some of the different surface finishes available for FRP pultrusion profiles include smooth, textured, non-skid, and glossy finishes. These finishes can enhance the aesthetics, improve grip, and provide protection against UV radiation and corrosion.

Send your message to us

FRP Pultrusion Profiles - Anti-Corrosion, Anti-Rust, High-Quality FRP Pultruded Grating

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords