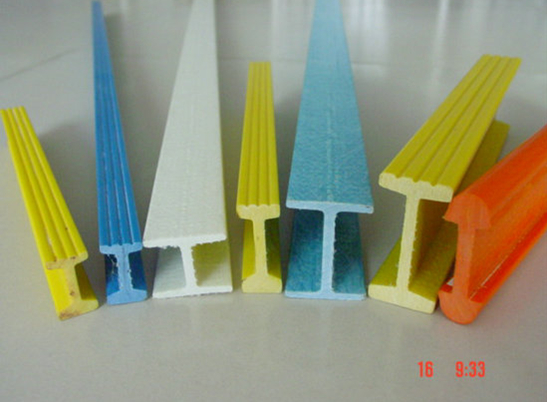

FRP Pultrusion Profiles - C Shape, I Shape

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 20000m m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description of FRP Pultrusion Profile

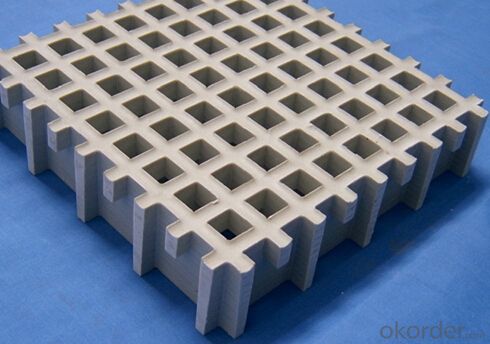

FRP Grating, Molded FRP Grating, Fiberglass Grating, GRP Grating,GRP Molded Grating,FRP Pultrusion Grating, FRP Mini Mesh Grating,Trench Grating, Drain Grating,Grating Walkway, Platform Grating...

Comparing with other floor materials, FRP molded grating provides a series of benefits, unmatched impact resistance,

while the strength-weight-ratio is only one-fourth of that of steel grating. It is easy to cut and install.

Specification of FRP Pultrusion Profile

Item | Thickness mm | Mesh Size mm*mm | Panel Size mm*mm | Weight kg/Square Meter |

01 | 15 | 38*38 | 1223*3660 | 7 |

02 | 15 | 50*50 | 1223*3660 | 6.5 |

03 | 25 | 25*100 | 1010*3010 | 12.4 |

04 | 25 | 19*19 | 1223*3660 | 12.5 |

05 | 30 | 19*19 | 1223*3660 | 21.5 |

06 | 30 | 38*38 | 1223*4040 | 15.1 |

07 | 38 | 19*19 | 1223*3660 | 22.8 |

08 | 38 | 38*38 | 1000*4040 | 19.5 |

09 | 38 | 38*38 | 1223*3660 | 19.5 |

10 | 40 | 40*40 | 1250*3690 | 19.3 |

11 | 50 | 50*50 | 1223*3660 | 21.5 |

Images

Features Of FRP Pultrusion Profile

1.Corrosion and Chemical resistant

2.Slip-resistant

3.High strength-to-weight ratio

4.Ergonomic

5.Low maintenance

6.Fire retardant

7.Easily fabricated and installed

FAQ:

1. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

- Q: Are FRP pultrusion profiles resistant to electrical arcing?

- FRP pultrusion profiles are generally resistant to electrical arcing. This is because they are made from non-conductive materials like fiberglass reinforced plastic. These profiles do not conduct electricity, which makes them ideal for applications where electrical arcing or conductivity is a concern. However, it is important to note that the specific resistance to electrical arcing may vary depending on the specific composition and design of the FRP pultrusion profiles. It is recommended to consult with the manufacturer or supplier of the profiles to ensure they meet the required electrical resistance standards for a particular application.

- Q: Are FRP pultrusion profiles resistant to biological growth, such as mold or mildew?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to biological growth, including mold and mildew. FRP materials are inherently non-porous, making it difficult for microorganisms to attach and grow on their surface. Additionally, FRP pultrusion profiles are typically manufactured using a combination of resin and glass fibers, which are both naturally resistant to biological growth. Unlike traditional materials such as wood or metal, FRP does not provide an ideal environment for mold or mildew to thrive. The smooth and non-porous surface of FRP profiles prevents moisture absorption, which is essential for the growth of microorganisms. Furthermore, FRP materials do not contain organic compounds that can support the growth of mold or mildew, making them highly resistant to biological degradation. In applications where resistance to biological growth is crucial, FRP pultrusion profiles offer a significant advantage over alternative materials. They are commonly used in environments with high humidity, moisture, or exposure to water, such as marine, agricultural, or wastewater treatment facilities. Additionally, FRP profiles are frequently employed in indoor applications where mold or mildew growth can be a concern, such as in sanitary areas or food processing plants. Overall, FRP pultrusion profiles provide excellent resistance to biological growth, including mold and mildew. Their non-porous nature, combined with the inherent resistance of the materials used in their manufacturing, make them a durable and long-lasting solution in environments where microbial growth is a potential issue.

- Q: Can FRP pultrusion profiles be used in the production of electrical insulators?

- Indeed, FRP pultrusion profiles have the potential to be utilized in the manufacturing of electrical insulators. These profiles are renowned for their exceptional electrical insulation characteristics, rendering them appropriate for a wide array of electrical applications. The non-conductive and high-strength attributes of FRP materials make them an ideal choice for insulating components within electrical systems, including insulators. The creation of FRP pultrusion profiles entails saturating continuous fibers like fiberglass, carbon fiber, or aramid with a polymer resin, which is subsequently solidified and shaped through the pultrusion process. This process yields a resilient and lightweight material that exhibits remarkable electrical insulation properties. Electrical insulators serve the purpose of obstructing the flow of electric current between conductive materials or components. They are indispensable in electrical systems as they ensure safety and prevent electrical leakage or short circuits. FRP pultrusion profiles can be tailored and manufactured to meet the specific requisites of electrical insulators, encompassing dimensional accuracy, mechanical strength, and electrical insulation performance. Moreover, FRP pultrusion profiles offer numerous advantages when compared to conventional materials such as wood, porcelain, or ceramics. They possess corrosion resistance, possess a high strength-to-weight ratio, and can be easily customized to fulfill the specific demands of electrical insulator applications. Furthermore, FRP pultrusion profiles are non-conductive, a pivotal factor for electrical insulation. In summary, owing to their exceptional electrical insulation properties, durability, lightweight nature, and customization possibilities, FRP pultrusion profiles are exceedingly suitable for the production of electrical insulators.

- Q: What are the best manufacturers of glass fiber reinforced plastic pultruded profiles in China?

- We have made 2.5mm thick at the moment

- Q: What is the dimensional stability of FRP pultrusion profiles?

- FRP pultrusion profiles exhibit a remarkably high level of dimensional stability, owing to the unique structural characteristics of FRP materials and the pultrusion manufacturing process. To create FRP pultrusion profiles, continuous fibers, such as glass or carbon, are drawn through a resin bath and then heated die. The resin, typically a thermosetting polymer, undergoes a chemical reaction during curing to transform into a rigid and durable material. The pultrusion process ensures an even distribution and alignment of fibers within the profile, resulting in a remarkably uniform and consistent material. This uniformity significantly contributes to the dimensional stability of FRP pultrusion profiles. In addition, the thermosetting nature of the resin matrix ensures exceptional dimensional stability. Once cured, the resin retains its shape and dimensions, even when subjected to varying temperature and humidity conditions. Consequently, FRP pultrusion profiles are resistant to warping, shrinking, or expanding, issues commonly encountered with materials like wood or metals. The exceptional dimensional stability of FRP pultrusion profiles makes them exceptionally well-suited for a wide range of applications that demand precise and consistent dimensions. These profiles are widely used in industries such as construction, infrastructure, transportation, and marine, where their ability to maintain their shape and dimensions over time is essential for long-term performance and structural integrity.

- Q: Are FRP pultrusion profiles resistant to electrical surges or lightning strikes?

- FRP pultrusion profiles have inherent electrical insulation properties due to their composition of fiberglass reinforcement and resin matrix. This insulation makes them resistant to electrical surges and lightning strikes to some extent. However, it is important to note that no material can provide absolute protection against extremely high voltage electrical surges or direct lightning strikes. In such cases, additional measures like grounding and lightning protection systems are necessary to ensure the safety of structures or equipment. Therefore, while FRP pultrusion profiles offer some level of resistance to electrical surges and lightning strikes, it is advisable to consult with experts and adhere to relevant safety standards when designing and installing electrical systems in areas prone to such events.

- Q: How do FRP pultrusion profiles handle compression loads?

- The unique and effective handling of compression loads by FRP pultrusion profiles is attributed to their structure and material composition. By pulling continuous fibers, such as glass or carbon, through a resin bath and a heated die, the profiles are formed and cured. In terms of compression loads, FRP pultrusion profiles demonstrate exceptional performance. The incorporation of continuous fibers within the resin matrix results in highly rigid and strong profiles, enabling them to effectively withstand compressive forces. The fibers evenly distribute the load along the profile's length, preventing localized failure and ensuring overall structural integrity. Furthermore, the fiber reinforcement in FRP pultrusion profiles provides excellent resistance against buckling. Buckling occurs when excessive compressive loads cause instability and failure in slender structural members. The robust strength-to-weight ratio of the fibers helps prevent buckling, allowing the profiles to endure significant compression forces without compromising their structural integrity. Moreover, the resin matrix in FRP pultrusion profiles plays a vital role in handling compression loads. It acts as a protective layer, safeguarding the fibers from damage or fractures caused by compressive forces. Additionally, the resin serves as a medium for load transfer, effectively distributing the compressive load to the fibers, which then carry it throughout the entire profile. In summary, FRP pultrusion profiles are exceptionally well-suited for managing compression loads due to their fiber reinforcement and resin matrix. They offer remarkable strength, stiffness, and resistance to buckling, making them an ideal choice for various applications where compression loads are a concern.

- Q: Are FRP pultrusion profiles resistant to corrosion and chemicals?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to corrosion and chemicals. FRP is composed of a combination of reinforcing fibers, such as fiberglass, and a polymer resin matrix. This unique composition provides excellent resistance to a wide range of corrosive environments and chemicals. FRP pultrusion profiles have inherent corrosion resistance due to the absence of metal components. Unlike metals that can corrode when exposed to moisture, oxygen, or certain chemicals, FRP does not rust or deteriorate. This makes FRP pultrusion profiles an ideal choice for applications in industries such as chemical processing, wastewater treatment, marine, and oil and gas. Furthermore, FRP pultrusion profiles are highly resistant to a variety of chemicals, including acids, alkalis, solvents, and salts. The polymer resin matrix used in FRP provides a protective barrier that prevents chemical penetration and degradation of the structural profile. This resistance to chemicals ensures that FRP pultrusion profiles can withstand harsh environments without suffering from corrosion or material degradation. In summary, FRP pultrusion profiles are indeed resistant to corrosion and chemicals. Their non-metallic composition and protective polymer resin matrix make them highly durable and suitable for a wide range of applications where corrosion and chemical resistance are crucial.

- Q: Are FRP pultrusion profiles resistant to humidity or moisture?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to humidity and moisture. The combination of fiberglass reinforcement and a polymer resin matrix makes them inherently resistant to water absorption. Unlike traditional materials like wood or metal, FRP pultrusion profiles do not swell, warp, or corrode when exposed to moisture or high humidity levels. This resistance to moisture makes FRP pultrusions suitable for a wide range of applications in various industries, including construction, infrastructure, and marine environments. Additionally, FRP pultrusion profiles can be further enhanced with additional protective coatings or surface finishes to provide even greater resistance to moisture and humidity.

- Q: Do FRP pultrusion profiles require any special tools for installation?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles do require some special tools for installation. Pultrusion profiles are manufactured using a continuous process that involves pulling fibers through a resin bath and then into a heated die, resulting in a strong, lightweight, and corrosion-resistant material. To properly install FRP pultrusion profiles, some specific tools are commonly used. These tools include: 1. Cutting Tools: FRP profiles may need to be cut to specific lengths during installation. Special cutting tools, such as high-speed saws or abrasive wheels, are often used to ensure clean and precise cuts. 2. Drilling Tools: FRP profiles may require holes to be drilled for fasteners or other fittings. Special drill bits designed for working with composite materials are typically used to avoid damaging the profile while creating the necessary holes. 3. Fastening Tools: Depending on the application, FRP profiles may need to be fastened to other surfaces or structures. Special fasteners like stainless steel screws, bolts, or adhesives are commonly used to secure the profiles in place. 4. Joining Tools: In certain cases, FRP profiles may need to be joined together to create longer lengths or more complex shapes. Special joining techniques like bonding, riveting, or using mechanical connectors are employed to ensure a strong and secure connection. It is important to note that the specific tools required for installation may vary based on the project's complexity, size, and the manufacturer's recommendations. Therefore, it is always advisable to consult the manufacturer's installation guidelines or seek professional assistance to ensure proper installation and to maximize the performance of FRP pultrusion profiles.

Send your message to us

FRP Pultrusion Profiles - C Shape, I Shape

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 20000m m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords