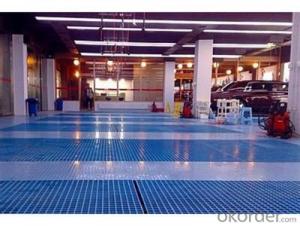

FRP Pultrusion Profiles for Carwash Floor High Strength Grating

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of FRP Grating for Carwash Floor:

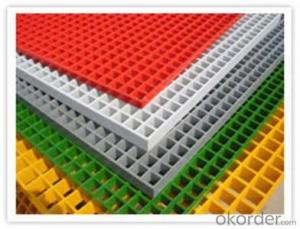

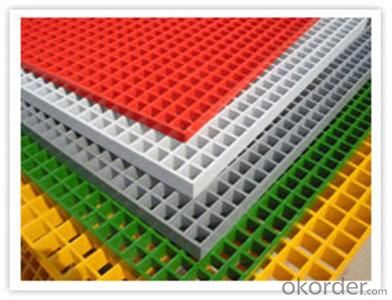

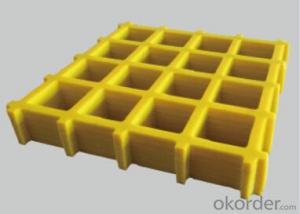

- FRP grating for carwash square hole specifications: (38 * 38mm) 50 * 50mm

- FRP grating for carwash thickness basically divided into: (25mm 30mm 38mm) 50mm

- FRP grating for carwashe commonly used colors: yellow / green / gray / black

- FRP grating entire board size: 1.22 * 3.66m = 4.4652 (meters)

- Carwash station Size:

Standard Parking: 3 * 6.1 m

Small Spaces: 2.44 * 4.88 m (recommended)

The parking: 3.66 * 4.88 m

Large spaces: 3.66 * 6.1 m

- FRP grating thickness:

25mm thickness: Suitable for general drains, the inner diameter of the support groove width not exceeding 20cm, can load about 2 tons of pressure off the car.

38mm thick: for gutters and carwash station, but the following support center spacing (horizontal and vertical) to no more than 50cm better, the car can carry three tons or less.

Detailed consultation: contact us.

- Q: Can FRP pultrusion profiles be used in the construction of railway sleepers?

- The use of FRP (Fiber Reinforced Polymer) pultrusion profiles is indeed possible in the construction of railway sleepers. These profiles possess a range of advantages that render them suitable for this particular application. To begin with, the lightweight yet robust nature of FRP pultrusion profiles makes them an ideal option for railway sleepers. They boast high strength-to-weight ratios, enabling them to withstand heavy loads and reliably support the weight of trains. Moreover, their lightweight constitution facilitates transportation and installation, thereby reducing construction time and costs. Additionally, FRP pultrusion profiles exhibit a high resistance to corrosion, a crucial aspect for railway sleepers. Unlike traditional materials such as wood or steel that are prone to corrosion when exposed to moisture and chemicals, FRP profiles are non-corrosive. Consequently, they do not necessitate regular maintenance or replacement due to rust or decay. Furthermore, these profiles offer exceptional durability and longevity. They can withstand UV radiation, extreme temperatures, and chemicals, ensuring a longer lifespan compared to conventional materials. As a result, the need for frequent replacements is minimized, leading to reduced maintenance and lifecycle costs. Moreover, FRP pultrusion profiles can be tailored to meet specific design requirements. They can be manufactured in various shapes and sizes to accommodate different railway sleeper designs, providing flexibility in construction. Additionally, they can be produced in different colors, allowing for aesthetic customization. Lastly, FRP pultrusion profiles possess excellent electrical insulation properties, a critical factor for railway sleepers. They are capable of providing insulation between the train tracks and the ground, preventing electrical interference and ensuring safe operation. In conclusion, FRP pultrusion profiles are a suitable choice for constructing railway sleepers due to their lightweight yet strong composition, corrosion resistance, durability, customization options, and electrical insulation properties.

- Q: Can FRP pultrusion profiles be used in telecommunications towers?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in telecommunications towers. FRP materials offer several advantages for such applications, including high strength-to-weight ratio, corrosion resistance, and electrical non-conductivity. These properties make FRP pultrusion profiles suitable for use in telecommunications towers, providing structural support while offering durability and longevity.

- Q: Are FRP pultrusion profiles fire resistant?

- FRP pultrusion profiles exhibit excellent fire resistance due to the combination of reinforcing fibers and the polymer matrix employed in their production. These profiles are crafted through the pultrusion process, wherein reinforcing fibers like fiberglass or carbon fiber are impregnated with a thermosetting resin. This resin undergoes a curing process, resulting in a robust and durable composite material. One of the primary advantages of FRP pultrusion profiles lies in their inherent fire resistance. The thermosetting resin utilized in their manufacture possesses properties that render it highly impervious to fire. When subjected to flames or elevated temperatures, the resin does not easily burn or melt, thereby impeding the propagation of fire. Moreover, the reinforcing fibers present in FRP profiles contribute significantly to their fire resistance. For example, fiberglass, being an inorganic substance, does not combust. It serves as a heat transfer barrier, aiding in the containment of flames. Additionally, FRP pultrusion profiles can be engineered to meet specific fire safety standards and regulations. By incorporating supplementary fire retardant additives or employing specialized resin systems, the fire resistance of these profiles can be further enhanced. It is crucial to note that although FRP pultrusion profiles do possess fire resistance, their precise fire rating may vary depending on the particular composition and design. Thus, it is imperative to consult manufacturers or suppliers who can furnish comprehensive information regarding the fire resistance properties of their FRP pultrusion profiles.

- Q: Can FRP pultrusion profiles be used in wastewater or sewage treatment plants?

- FRP pultrusion profiles are applicable for use in wastewater or sewage treatment plants. These materials possess exceptional resistance against corrosion, making them an ideal option for environments that frequently encounter chemicals, moisture, and harsh conditions, such as wastewater treatment plants. Compared to conventional materials like steel or concrete, FRP pultrusion profiles offer numerous advantages. They are lightweight, yet incredibly sturdy and long-lasting, facilitating easy installation while maintaining resistance against damage or degradation over time. Additionally, FRP profiles possess non-conductive properties and display good thermal insulation, which can prove advantageous in specific applications within wastewater treatment plants. Moreover, FRP materials exhibit immunity to corrosion and rust, even when exposed to aggressive chemicals and gases commonly present in wastewater or sewage treatment plants. This corrosion resistance significantly prolongs the lifespan of FRP pultrusion profiles, thereby reducing the necessity for frequent maintenance and replacement. To summarize, owing to their corrosion resistance, durability, and other favorable properties, FRP pultrusion profiles are an appropriate choice for a variety of applications in wastewater or sewage treatment plants, including walkways, platforms, handrails, grating, and structural supports.

- Q: What are the features of Glass Fiber Reinforced Plastic Pultruded materials and chairs?

- Glass fiber reinforced plastic extruded sections for chair bars, corrosion resistance, aging resistance, good decorative (wood grain glass fiber reinforced plastic), Candice's color wood grain felt.No recycling value. I'd say that's probably the best feature right now. Installed, no one cares about, will not lose!

- Q: Can FRP pultrusion profiles be used in the construction of playground equipment?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of playground equipment. FRP pultrusion profiles are known for their high strength-to-weight ratio, corrosion resistance, and durability, making them suitable for outdoor applications like playground equipment. These profiles can be used to create various structures such as slides, climbing frames, and play structures. Additionally, FRP pultrusion profiles can be molded into different shapes and sizes, allowing for flexibility in design and customization of playground equipment. Additionally, FRP materials are non-conductive, making them safe for children to use. Overall, FRP pultrusion profiles offer numerous benefits that make them a suitable choice for the construction of playground equipment.

- Q: Are FRP pultrusion profiles resistant to chemicals used in mining operations?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to chemicals used in mining operations. FRP materials are known for their excellent chemical resistance properties, making them suitable for various corrosive environments, including mining operations. The resin matrix used in FRP pultrusion profiles can be selected to provide resistance against a wide range of chemicals commonly found in mining applications, such as acids, alkalis, solvents, and corrosive gases. Additionally, the reinforcement fibers, usually made of glass or carbon, further enhance the overall chemical resistance of the profile. Furthermore, FRP pultrusion profiles are non-conductive, which makes them an ideal choice for electrical and mining applications. They do not corrode or degrade under exposure to chemicals, ensuring durability and longevity in harsh mining environments. However, it is essential to consider the specific chemicals and concentrations used in mining operations. While FRP pultrusion profiles have excellent chemical resistance in general, prolonged exposure to extremely aggressive chemicals or high concentrations may require additional measures, such as selecting specific resin systems or surface coatings, to ensure optimal performance and longevity. It is advisable to consult with FRP manufacturers or experts to determine the best-suited materials for specific mining chemical environments.

- Q: Are FRP pultrusion profiles UV resistant?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are typically UV resistant. This is because they are manufactured using a combination of polymer resin and reinforced fibers such as fiberglass. These materials have inherent UV resistant properties, making FRP pultrusion profiles resistant to damage caused by prolonged exposure to sunlight and ultraviolet radiation. UV resistance is a crucial characteristic for outdoor applications where the profiles will be exposed to sunlight, such as in construction, infrastructure, and marine industries. However, it is important to note that the level of UV resistance may vary depending on the specific resin and fiber composition used in the manufacturing process. Therefore, it is recommended to consult the manufacturer or supplier for specific information on the UV resistance of FRP pultrusion profiles for a particular application.

- Q: Can FRP pultrusion profiles be used in the construction of agricultural structures?

- Yes, FRP pultrusion profiles can be used in the construction of agricultural structures. FRP pultrusion profiles are lightweight, durable, and resistant to corrosion, making them suitable for various agricultural applications such as greenhouse framing, livestock enclosures, and storage sheds. They offer excellent strength-to-weight ratio and can withstand harsh environmental conditions, making them a reliable choice for agricultural construction.

- Q: Can FRP pultrusion profiles be used in the renewable energy and solar power industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be effectively used in the renewable energy and solar power industry. FRP pultrusion profiles possess several key characteristics that make them ideal for such applications. Firstly, FRP pultrusion profiles have high strength-to-weight ratio, meaning they are lightweight yet strong, which is crucial in the renewable energy sector where materials need to withstand various environmental conditions while being cost-effective. Secondly, FRP pultrusion profiles offer excellent corrosion resistance, ensuring durability and longevity in outdoor and potentially corrosive environments, such as solar power plants or wind farms. Additionally, these profiles have excellent electrical insulation properties, making them suitable for electrical applications commonly found in the renewable energy industry. Moreover, FRP pultrusion profiles can be easily customized into various shapes and sizes, enabling the design and engineering of complex structures required for solar power installations or wind turbine blades. Furthermore, FRP materials are non-conductive and non-magnetic, making them safe for use in electrical and magnetic fields associated with renewable energy systems. Overall, FRP pultrusion profiles offer a combination of strength, durability, lightweight, corrosion resistance, and electrical insulation properties that make them highly suitable for use in the renewable energy and solar power industry.

Send your message to us

FRP Pultrusion Profiles for Carwash Floor High Strength Grating

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords