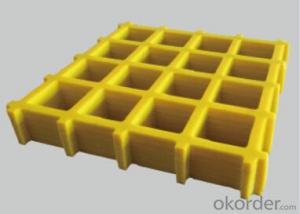

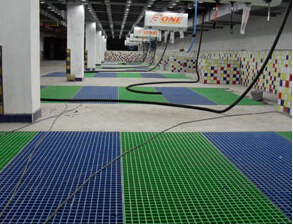

FRP Pultrusion Profiles for Carwash Floor Grating - CNBM Group

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of FRP Grating:

Light weight of FRP grating: the proportion of it is about 1.8, its weight was only about a quarter of the steel, is two-thirds of aluminum;

High strength of FRP grating: the strength is ten times the rigid polyvinyl chloride (PVC), absolute strength much more than aluminum, to achieve the level of the ordinary steel;

Corrosion resistanceof FRP grating: it does not rust, no mold, no corruption, no need to paint, can a lot of gas and liquid medium corrosion;

Fatigue resistance of FRP grating: FRP gratings have some flexibility, which makes people working on it for a long time to feel comfortable, as a work platform, reduce the staff in the legs and back tension and increase the work of comfort, so as to improve the work efficiency, recommended by human engineers;

Comprehensive economic benefit is good: with ordinary carbon steel, FRP grating comprehensive cost is low, although its one-time investment is higher than the ordinary carbon steel, because of its long service life, generally can be used for twenty years, and no maintenance, thus FRP grating's comprehensive economic benefit is significantly superior to use carbon steel;

Convenient installation of FRP grating: the use of FRP gratings greatly reduce components weight, thereby reducing the weight of the support structure, do not need to use the lifting equipment installation, saving and convenient.

Security of FRP grating: in the process of installation and use of FRP grating will not produce edm by collision, especially suitable for use in flammable and explosive environment, in addition, with non-slip surface of the grating can prevent slipping, reduce accidents;

To sum up, FRP grating compared with the traditional metal and non-metal materials, FRP grating materials and products, with high strength, good performance, energy conservation, product design degrees of freedom, and product use wide adaptability, etc. Therefore, in a certain sense, the FRP grating materials is a kind of a wide range of application, one of the great varieties of materials development prospects.

- Q: What are the typical applications of FRP pultrusion profiles?

- FRP pultrusion profiles possess unique properties that make them applicable in various fields. Examples of their typical uses include: 1. Construction and Infrastructure: FRP profiles serve as structural elements in buildings, bridges, and infrastructure projects. They are commonly employed for beams, columns, decks, and reinforcement due to their impressive strength-to-weight ratio, resistance to corrosion, and durability. 2. Industrial and Chemical Processing: The industrial sector heavily utilizes FRP profiles for platforms, walkways, ladders, and handrails. These profiles exhibit excellent resistance to chemicals, heat, and corrosion, making them well-suited for harsh environments. 3. Electrical and Telecommunication: FRP profiles find utility in electrical and telecommunication systems, fulfilling roles such as cable trays, ladder racks, and support structures. They provide electrical insulation and are non-conductive, ensuring safety and reliability in these applications. 4. Transportation: The transportation industry benefits from FRP profiles, particularly in the production of lightweight components for vehicles like buses, trains, and trucks. These profiles aid in weight reduction, improve fuel efficiency, and enhance overall vehicle performance. 5. Marine and Offshore: FRP pultrusion profiles excel in marine and offshore applications due to their resistance to saltwater, UV radiation, and harsh environmental conditions. They are employed in boat hulls, piers, dock fenders, and other offshore structures. 6. Recreation and Sports: FRP profiles contribute to the production of recreational equipment like ladders, slides, playground equipment, and sports accessories. Their strength, durability, and weather resistance make them ideal for these applications. 7. Water Treatment and Wastewater Management: FRP profiles find extensive use in water treatment plants, sewage systems, and wastewater management facilities. They fulfill roles such as grating, handrails, ladders, and other structural components due to their resistance to chemicals and corrosion. In summary, the versatility, strength, corrosion resistance, and lightweight nature of FRP pultrusion profiles make them suitable for diverse applications in various industries.

- Q: Can FRP pultrusion profiles be used in the water treatment industry?

- Indeed, the water treatment industry can make use of FRP pultrusion profiles. These profiles, made of Fiber Reinforced Polymer, are widely recognized for their exceptional resistance to corrosion, impressive strength, and long-lasting durability. These qualities render them highly appropriate for a diverse range of applications within the water treatment field. In particular, FRP pultrusion profiles can be employed in the construction of water treatment tanks, pipes, and other crucial infrastructure. They exhibit remarkable resistance to chemicals, including those commonly employed in water treatment procedures. This resistance to corrosion ensures that equipment enjoys an extended lifespan and maintenance costs are minimized. Moreover, FRP pultrusion profiles boast an impressive strength-to-weight ratio, making them an ideal choice for applications that necessitate lightweight yet robust materials. This quality facilitates the easier installation and transportation of water treatment equipment. Furthermore, the flexibility in design offered by FRP pultrusion profiles is worth noting. Such profiles can be manufactured in a wide array of shapes and sizes to cater to specific project requirements. This capability allows for the customization and optimization of water treatment systems, guaranteeing the efficiency and effectiveness of water treatment processes. In summary, FRP pultrusion profiles present themselves as a dependable and cost-effective option for the water treatment industry. Their excellent resistance to corrosion, exceptional strength, and design flexibility make them highly suitable for numerous applications within water treatment systems.

- Q: How do FRP pultrusion profiles perform in electrical grounding systems?

- FRP (Fiber Reinforced Polymer) pultrusion profiles have shown promising performance in electrical grounding systems. These profiles are made of a combination of fibers, such as glass or carbon, and a polymer resin matrix, which provides high strength, durability, and corrosion resistance. One of the key advantages of FRP pultrusion profiles in electrical grounding systems is their excellent electrical insulation properties. Unlike metals, which conduct electricity, FRP profiles have a very high resistance to electrical current, making them ideal for applications where electrical isolation is crucial. This property helps prevent the risk of electrical shock hazards and reduces the potential for short circuits. Additionally, FRP pultrusion profiles offer high mechanical strength while being lightweight. This makes them easy to handle and install, reducing labor costs and time. The profiles are also resistant to UV radiation, chemicals, and moisture, ensuring long-term performance and durability in various environmental conditions. Another benefit of FRP pultrusion profiles is their resistance to corrosion. Unlike metals, which can rust and deteriorate over time, FRP profiles are immune to corrosion, making them ideal for use in harsh or corrosive environments. This corrosion resistance ensures the longevity and reliability of the electrical grounding system. Furthermore, FRP pultrusion profiles are non-magnetic, which is advantageous in applications where magnetic interference needs to be minimized or eliminated. This characteristic prevents any interference with sensitive electrical equipment and ensures accurate electrical measurements. Overall, FRP pultrusion profiles offer a range of advantages in electrical grounding systems. Their excellent electrical insulation properties, high mechanical strength, corrosion resistance, lightweight nature, and non-magnetic characteristics make them a reliable and efficient choice for ensuring safe and reliable electrical grounding.

- Q: How do FRP pultrusion profiles perform in heavy-load applications?

- FRP pultrusion profiles perform exceptionally well in heavy-load applications. Due to their high strength-to-weight ratio and excellent load-bearing capabilities, they are able to withstand heavy loads without compromising on performance or structural integrity. Moreover, their resistance to corrosion, chemicals, and extreme weather conditions further enhances their suitability for heavy-load applications.

- Q: How do FRP pultrusion profiles handle cyclic torsion loads?

- FRP pultrusion profiles are designed to handle cyclic torsion loads effectively due to their inherent properties. The continuous fibers in the profiles provide high strength and stiffness, enabling them to withstand repeated twisting without deformation or failure. Additionally, the resin matrix used in the pultrusion process offers excellent fatigue resistance, ensuring long-term durability and performance under cyclic torsion loads.

- Q: Are FRP pultrusion profiles fire resistant?

- Yes, FRP pultrusion profiles are fire resistant.

- Q: Are FRP pultrusion profiles impact resistant?

- FRP pultrusion profiles are widely recognized for their exceptional impact resistance. By combining reinforcing fibers like glass or carbon with a polymer matrix, they become intrinsically sturdy and long-lasting. The pultrusion process further bolsters their impact resistance by aligning the fibers in the direction of the load, providing optimal strength against impacts. Additionally, these profiles boast a remarkable strength-to-weight ratio, enabling them to withstand heavy impacts without significant damage or deformation. This characteristic makes them ideal for industries like construction, transportation, and infrastructure, where impact resistance is vital. Furthermore, FRP pultrusion profiles exhibit outstanding resistance to corrosion, chemicals, and UV radiation, enhancing their durability and long-term performance. Even in harsh environments, they maintain their impact resistance properties, making them the preferred choice for various sectors. Nonetheless, it is crucial to acknowledge that the impact resistance of FRP pultrusion profiles can vary depending on factors like design, composition, and manufacturing process. To ensure the profiles meet the desired impact resistance requirements for a specific application, it is advisable to consult with the manufacturer or supplier.

- Q: Can FRP pultrusion profiles be used in the construction of outdoor signage?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of outdoor signage. FRP pultrusion profiles are known for their durability, strength, and resistance to various environmental conditions, making them suitable for outdoor applications. These profiles are typically made of a combination of fiberglass reinforcement and resin matrix, resulting in a lightweight yet strong material. Outdoor signage often needs to withstand harsh weather conditions, such as rain, sun exposure, and temperature fluctuations. FRP pultrusion profiles have excellent resistance to corrosion, UV rays, and moisture, ensuring that the signage can maintain its structural integrity and visual appeal over time. Furthermore, FRP pultrusion profiles can be customized to meet specific design requirements, allowing for flexibility in creating unique and eye-catching outdoor signage. These profiles can be easily shaped, cut, and assembled, making them a versatile choice for signage applications. In summary, FRP pultrusion profiles can indeed be used in the construction of outdoor signage due to their durability, resistance to environmental conditions, and flexibility in design.

- Q: Is the test standard for FRP pultruded profiles and FRP gratings the same?

- Not the same. You can consult Hao Hao testing company (national level)

- Q: Can FRP pultrusion profiles be used in wastewater treatment facilities?

- Indeed, FRP pultrusion profiles have the capability to be utilized in wastewater treatment facilities. These profiles possess numerous benefits, including a high strength-to-weight ratio, resistance to corrosion, and durability, all of which make them highly suitable for the challenging conditions found in such facilities. In wastewater treatment facilities, there exists a wide range of applications where FRP pultrusion profiles can be effectively employed. These applications encompass walkways, handrails, ladders, grating, and structural supports, among others. The corrosion resistance of FRP makes it particularly well-suited for deployment in areas that are exposed to moisture and the chemicals present in wastewater. Furthermore, the lightweight nature of FRP profiles simplifies the installation process and reduces the burden placed on supporting structures. The durability of FRP pultrusion profiles guarantees long-term performance, even in aggressive environments. They exhibit a remarkable resistance to chemical attacks, UV radiation, and bacterial growth, rendering them highly appropriate for wastewater treatment applications. Additionally, FRP profiles can be tailored to meet specific load requirements and can be easily fabricated to accommodate various shapes and sizes. Furthermore, FRP pultrusion profiles possess outstanding electrical insulation properties, which can prove advantageous in wastewater treatment facilities where electrical safety is of utmost concern. To summarize, FRP pultrusion profiles can be effectively employed in wastewater treatment facilities due to their corrosion resistance, durability, lightweight nature, and versatility in terms of design and fabrication. These profiles provide long-lasting solutions for a variety of applications within these facilities, ensuring operational efficiency and minimizing maintenance needs.

Send your message to us

FRP Pultrusion Profiles for Carwash Floor Grating - CNBM Group

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords