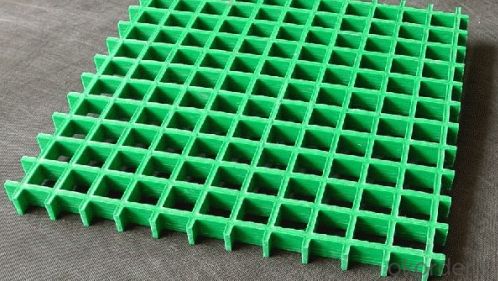

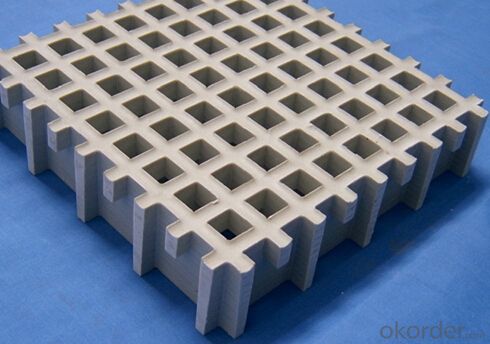

GRP Molded Grating for All Kinds Of Waterproof Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 30000 m2 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description of FRP Grating

FRP Grating, Molded FRP Grating, Fiberglass Grating, GRP Grating,GRP Molded Grating,FRP Pultrusion Grating, FRP Mini Mesh Grating,Trench Grating, Drain Grating,Grating Walkway, Platform Grating...

Comparing with other floor materials, FRP molded grating provides a series of benefits, unmatched impact resistance,

while the strength-weight-ratio is only one-fourth of that of steel grating. It is easy to cut and install.

Specification of FRP Grating

Item | Thickness mm | Mesh Size mm*mm | Panel Size mm*mm | Weight kg/Square Meter |

01 | 15 | 38*38 | 1223*3660 | 7 |

02 | 15 | 50*50 | 1223*3660 | 6.5 |

03 | 25 | 25*100 | 1010*3010 | 12.4 |

04 | 25 | 19*19 | 1223*3660 | 12.5 |

05 | 30 | 19*19 | 1223*3660 | 21.5 |

06 | 30 | 38*38 | 1223*4040 | 15.1 |

07 | 38 | 19*19 | 1223*3660 | 22.8 |

08 | 38 | 38*38 | 1000*4040 | 19.5 |

09 | 38 | 38*38 | 1223*3660 | 19.5 |

10 | 40 | 40*40 | 1250*3690 | 19.3 |

11 | 50 | 50*50 | 1223*3660 | 21.5 |

Images

Features

1.Corrosion and Chemical resistant

2.Slip-resistant

3.High strength-to-weight ratio

4.Ergonomic

5.Low maintenance

6.Fire retardant

7.Easily fabricated and installed

FAQ:

1. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

3. Payment terms?

We can accept L/C, T/T etc.

- Q: How do FRP pultrusion profiles perform in high-vibration applications?

- High-vibration applications are where FRP (Fiber Reinforced Polymer) pultrusion profiles truly excel. The exceptional properties of FRP materials make them an ideal choice for these situations. To begin with, FRP pultrusion profiles are renowned for their impressive strength-to-weight ratio. Unlike traditional materials like steel or aluminum, FRP profiles are significantly lighter while still possessing remarkable strength and rigidity. This lightweight quality reduces the overall mass of the structure, resulting in lower vibration amplitudes. Furthermore, FRP materials boast outstanding damping characteristics. Damping refers to a material's ability to dissipate energy and decrease vibration amplitudes. In comparison to other materials, FRP pultrusion profiles have a higher damping coefficient, meaning they can more effectively absorb and dissipate vibrations. This minimizes the transmission of vibrations throughout the structure, reducing the risk of resonance and fatigue failure. In addition, FRP pultrusion profiles demonstrate exceptional resistance to fatigue and corrosion. Vibrations can cause cyclic loading, which can lead to fatigue failure over time. However, the inherent properties of FRP materials, including their excellent tensile strength and resistance to environmental factors, make them highly resilient to fatigue and corrosion. This guarantees the longevity and durability of the profiles, even in high-vibration environments. Moreover, FRP pultrusion profiles offer immense design flexibility, allowing for customized shapes and sizes that can be tailored to specific applications. This flexibility allows engineers to optimize the profiles' performance in high-vibration scenarios by adjusting the geometry and composition to enhance their dynamic characteristics. In summary, FRP pultrusion profiles are exceptionally suited for high-vibration applications due to their lightweight nature, excellent damping characteristics, resistance to fatigue and corrosion, and design flexibility. These profiles provide a reliable and durable solution that can effectively withstand the challenges posed by vibrations, ensuring safe and efficient operation in such environments.

- Q: Can FRP pultrusion profiles be used in architectural or decorative applications?

- Yes, FRP pultrusion profiles can be used in architectural or decorative applications. They offer various advantages such as high strength-to-weight ratio, resistance to corrosion and UV radiation, and design flexibility. Additionally, FRP pultrusion profiles can be customized to match specific aesthetic requirements, making them suitable for architectural and decorative purposes.

- Q: The difference between polyurethane pultruded profiles and glass reinforced plastic profiles

- The polyurethane pultrusion section is a product formed by mixing the polyol and a reactive isocyanate easily and quickly.Isocyanate is to optimize the molding characteristics and selection, these characteristics are: low viscosity (good impregnation fiber), gel time (easy to start and stop), rapid polymerization (improve molding speed), good surface finish, cost competitive.

- Q: Are FRP Pultruded Shapes poisonous?

- It shouldn't be poisonous. He can use it in a lot of production and life, especially all kinds of pipes, including water pipes

- Q: How do FRP pultrusion profiles handle torsion loads?

- FRP pultrusion profiles are renowned for their exceptional mechanical properties and impressive strength-to-weight ratio, making them an optimal selection for managing torsion loads. When exposed to torsion, these profiles are engineered to endure twisting forces and sustain their structural integrity. The construction of these profiles is pivotal to their capacity for handling torsion loads. FRP pultrusion profiles are crafted by pulling reinforcing fibers, such as fiberglass, through a bath of resin and subsequently through a heated die. This process aligns the fibers in the direction of the load, resulting in remarkable strength and rigidity. In the case of torsion loads, the aligned fibers within the profile's cross-section resist the twisting force by distributing it along the profile's length. This distribution of force aids in averting localized stress concentrations, thereby diminishing the risk of deformation or failure. Furthermore, the resin matrix encompassing the fibers acts as a binding agent, securing the fibers together and providing defense against environmental elements such as moisture, chemicals, and UV radiation. This ensures the profile's long-term durability and stability when subjected to torsion loads. Moreover, FRP pultrusion profiles can be tailored with specific cross-sectional shapes and dimensions to enhance their torsional strength. By optimizing the geometric configuration, such as augmenting the wall thickness or adding reinforcing ribs, the profiles can be further reinforced to meet the desired requirements for torsion loads. All in all, FRP pultrusion profiles excel in managing torsion loads due to their inherent properties, manufacturing process, and design adaptability. Their ability to withstand twisting forces, combined with their lightweight nature, establishes them as a dependable and cost-efficient choice for diverse applications, including construction, infrastructure, aerospace, and automotive industries.

- Q: Can FRP pultrusion profiles be customized or tailored to specific project requirements?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be customized or tailored to specific project requirements. Pultrusion is a manufacturing process that allows for the creation of continuous fiber-reinforced composite profiles with a high level of design flexibility. The specific requirements of a project, such as dimensions, shapes, and mechanical properties, can be accommodated by adjusting the design and manufacturing parameters. The customization process begins with understanding the project's needs and specifications. This includes determining the desired profile dimensions, cross-sectional shape, and mechanical properties such as strength, stiffness, and durability. Based on these requirements, engineers and manufacturers can develop a tailored solution. The customization of FRP pultrusion profiles can be achieved through various means. Firstly, the choice of reinforcement materials, such as fiberglass, carbon fiber, or aramid fiber, can be selected based on the desired mechanical characteristics. The orientation and volume fraction of the fibers can also be adjusted to optimize the strength and stiffness of the profile. Additionally, the resin matrix used in the pultrusion process can be customized to enhance specific properties, such as fire resistance, chemical resistance, or UV resistance. Various resin systems, including polyester, vinyl ester, or epoxy, can be utilized to meet the project's requirements. Furthermore, the pultrusion process allows for the incorporation of additional features during manufacturing. This includes adding inserts, fastener holes, grooves, or other structural details to the profile. These modifications can be tailored to the specific project requirements, ensuring compatibility with the overall design and assembly. Overall, FRP pultrusion profiles offer a high degree of customization and tailoring to meet specific project requirements. This versatility makes them a popular choice in various industries, including construction, infrastructure, aerospace, and automotive, where lightweight, durable, and corrosion-resistant materials are needed.

- Q: Are FRP pultrusion profiles resistant to fire?

- FRP pultrusion profiles are known for their fire resistance. They are composed of a resin matrix and reinforcing fibers, such as fiberglass or carbon fiber, which contribute to their excellent fire resistance properties. The resin matrix used in FRP has a high flame resistance rating, while the reinforcing fibers are not easily combustible. Consequently, FRP pultrusion profiles have a high ignition temperature and are naturally self-extinguishing, meaning they stop burning once the flame source is removed. Moreover, FRP pultrusion profiles do not emit toxic fumes or smoke when exposed to fire, making them a safer choice compared to traditional materials like wood or steel. Nevertheless, it is important to acknowledge that the fire resistance of FRP pultrusion profiles may vary depending on the specific resin formulation and reinforcement material utilized.

- Q: Are FRP pultrusion profiles UV resistant?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are typically UV resistant. This is because they are manufactured using a combination of polymer resin and reinforced fibers such as fiberglass. These materials have inherent UV resistant properties, making FRP pultrusion profiles resistant to damage caused by prolonged exposure to sunlight and ultraviolet radiation. UV resistance is a crucial characteristic for outdoor applications where the profiles will be exposed to sunlight, such as in construction, infrastructure, and marine industries. However, it is important to note that the level of UV resistance may vary depending on the specific resin and fiber composition used in the manufacturing process. Therefore, it is recommended to consult the manufacturer or supplier for specific information on the UV resistance of FRP pultrusion profiles for a particular application.

- Q: Can FRP pultrusion profiles be used in the automotive manufacturing industry?

- Certainly! Fiber Reinforced Polymer (FRP) pultrusion profiles have the potential to be utilized within the automotive manufacturing sector. These profiles possess a number of advantages that render them appropriate for automotive applications. To begin with, one of the key benefits of FRP profiles is their lightweight nature, which aids in reducing the overall weight of vehicles. This is of utmost importance in enhancing fuel efficiency and decreasing emissions. Moreover, the reduced weight of FRP profiles enables improved handling and enhanced performance. Additionally, FRP profiles exhibit exceptional mechanical properties, including high strength and stiffness. These properties make them well-suited for integration into structural components of vehicles, such as chassis, body panels, and frames. FRP profiles are able to withstand heavy loads and offer excellent impact resistance, thereby ensuring the safety of both the vehicle and its occupants. Furthermore, FRP profiles possess outstanding corrosion resistance, a quality that is particularly advantageous in automotive applications. In contrast to traditional materials like steel, FRP profiles are impervious to rust and corrosion. Consequently, they are ideally suited for deployment in various automotive environments, including those that involve exposure to moisture, chemicals, and salt. Moreover, FRP pultrusion profiles can be customized to meet specific design requirements, thereby affording flexibility in the manufacturing process. They can be produced in a range of shapes and sizes, which allows for the design of intricate components. This design flexibility also permits customization and optimization of vehicle performance. Lastly, FRP profiles possess excellent thermal and electrical insulation properties. This renders them appropriate for applications where minimizing electrical conductivity or providing thermal insulation is necessary. On the whole, the combination of the lightweight nature, high strength, corrosion resistance, design flexibility, and insulation properties of FRP pultrusion profiles positions them as an ideal choice for deployment within the automotive manufacturing industry. Their usage can contribute to the development of more efficient, safe, and durable vehicles.

- Q: Are FRP pultrusion profiles resistant to high-pressure or corrosive fluids?

- Yes, FRP pultrusion profiles are highly resistant to both high-pressure fluids and corrosive fluids. The composition of FRP (Fiber Reinforced Polymer) with its fiberglass reinforcement and resin matrix provides exceptional strength and durability. This makes FRP pultrusion profiles ideal for applications that involve exposure to high-pressure or corrosive fluids, as they can withstand these conditions without compromising their structural integrity.

Send your message to us

GRP Molded Grating for All Kinds Of Waterproof Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 30000 m2 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords