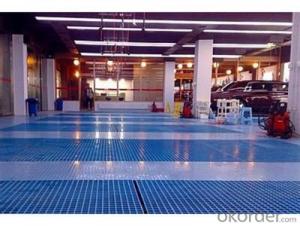

FRP Pultrusion Profiles for Carwash Floor New Style

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of FRP Grating for Carwash Floor:

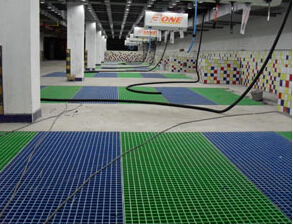

FRP grating for carwash floor is one kind of glass fiber reinforced plastic (FRP) by using glass fiber for reinforcement, unsaturated polyester resin as matrix, through special processing and become a kind of plate material, with lots of blank space in hebei leading production of glass FRP grasting can be used as a structural material, used for the floor of the corrosion environment, trench cover, platform, ship deck, stair, catwalks, etc.

FRP grating by glass fiber braiding, resin pouring the whole moulding, production with many rules of distribution of rectangle, square space of glass FRP grating plate, with two-way same-sex mechanics characteristics. FRP grating can be widely used in petroleum, chemical industry electronic, electric power, paper, printing and dyeing, electroplating, sewage treatment and other industries, Marine exploration work platforms, equipment platforms, drilling platform, walkway, etc., FRP grating is the ideal product in corrosive environment, at the same time can also be applied to civil construction facilities.

Due to our FRP grating can bear the presence of corrosive liquid, gas, metal corrosion rapidly in these areas, although the anti-corrosion layer and other measures, but for the components of the corrosion is still surprisingly, not only cause bad production environment, and affect production safety, FRP grating sometimes have to stop production maintenance, in the use of FRP grating as structural materials in these regions can have very good effect, it has a long service life, low cost, safe and reliable, no maintenance, and beautiful and easy, and a series of advantages. Of such products in the United States has used more than 30 years, the use, production sales of FRP grating has been standardization, seriation, commercialization, dosage is considerable. , the Middle East oil field in the gulf of reconstruction, the expert argumentation, and think that the use of FRP grating is the most economic and reasonable material, and therefore are a lot of use. In Asia, Singapore and other regions are also using FRP grating.

FRP grating performance characteristics are as follows:

Corrosion resistant

FRP grating has very excellent acid-proof, alkali resistance, resistance to organic solvents and salt, and many other gas and liquid medium corrosion performance, has the incomparable superiority in the field of anti-corrosion. According to the practical application requirements, can choose to use economically o-type, between benzene, vinyl resin base material.

Light weight, high strength, and is convenient for cutting, installation

Because it is by the resin and glass fiber composite, FRP grating density is not more than 2 kg each smaller CDM, is only a quarter of the steel, aluminum two-thirds. 10 times the strength of rigid polyvinyl chloride (PVC), absolute strength more than aluminum and the level of the ordinary steel. Its light weight, can greatly reduce the foundation support, thus reducing the material cost of the project. Its cutting easy installation, without hot and large-scale lifting equipment, only a small amount of manual and electric tools, makes the installation costs are greatly reduced.

Resistance to aging

In theory, the FRP grating service life of over 50 years.

Flame retardant

Ordinary FRP grating flame propagation rate (ASTM E - 84) is not more than 25; Advanced flame retardant vinyl grille the flame propagation rate of no more than 10. Oxygen index is not less than 28 (GB 8924).

Security of FRP Grating

FRP Grating has excellent electrical insulation, 10 kv voltage without breakdown; Without electricity, magnetic available in sensitive to magnetic devices; Glass fiber reinforced plastic FRP grating special structure also has the characteristics such as non-slip, anti-fatigue.

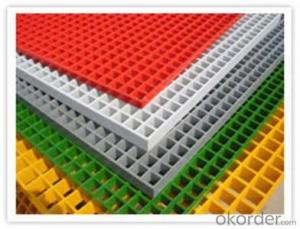

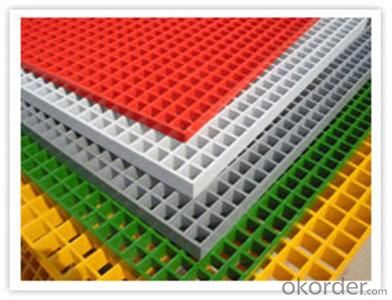

FRP Grating Color

Colors can be arbitrary choice. Can according to customer request custom color, improve the environment in the workplace. General FRP gratings are: yellow, black, grey, green, blue, red and transparent or translucent, etc. In use process can use a single color, also can match.

FRP Grating Can design a strong

Size flexible, convenient and cutting, size stability.

- Q: Are FRP pultrusion profiles resistant to hydrocarbons?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to hydrocarbons due to their inherent corrosion resistance properties. The composite materials used in FRP profiles provide excellent resistance to various chemicals, including hydrocarbons, making them suitable for applications in industries where exposure to such substances is common.

- Q: Are FRP pultrusion profiles resistant to earthquakes?

- FRP (Fiber Reinforced Polymer) pultrusion profiles can offer certain advantages when it comes to earthquake resistance. The inherent properties of FRP materials, such as high strength-to-weight ratio, flexibility, and damping characteristics, contribute to their ability to withstand seismic events. Additionally, FRP pultrusion profiles possess excellent fatigue resistance, which is crucial during earthquake-induced vibrations and aftershocks. One of the key advantages of FRP pultrusion profiles is their lightweight nature. Compared to traditional building materials like steel or concrete, FRP profiles are significantly lighter, reducing the overall mass of the structure. This weight reduction minimizes the inertia forces acting on the building during an earthquake, thus decreasing the potential for damage. Moreover, FRP materials exhibit high flexibility and ductility, allowing them to deform and absorb energy during seismic events. This flexibility helps in distributing the seismic forces more uniformly throughout the structure, reducing localized stress concentrations and enhancing the overall resilience of the building. The damping characteristics of FRP also contribute to dissipating the energy generated by an earthquake, further safeguarding the structure against damage. However, it is important to note that the earthquake resistance of any structure depends on several factors, including the design, construction, and adherence to relevant building codes and regulations. Proper engineering analysis and design must be employed to ensure that the FRP pultrusion profiles are appropriately incorporated into the structure to withstand the expected seismic forces. In summary, while FRP pultrusion profiles offer certain advantages in earthquake resistance, their effectiveness in protecting against seismic events relies on proper design and construction practices. It is crucial to work with experienced professionals and follow established guidelines to ensure the optimal performance of FRP structures during earthquakes.

- Q: Are FRP pultrusion profiles resistant to mold and mildew?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles are generally resistant to mold and mildew. FRP is a composite material made of a polymer matrix reinforced with fibers, typically glass fibers. Unlike organic materials such as wood or traditional plastics, FRP does not provide a suitable environment for mold and mildew growth. The inherent properties of FRP, such as its non-porous nature and resistance to moisture absorption, make it highly resistant to mold and mildew. Additionally, FRP pultrusion profiles are often manufactured with a smooth and glossy surface, which further inhibits the growth of mold and mildew. Furthermore, FRP is chemically inert, meaning it does not react with most substances. This characteristic makes FRP profiles highly resistant to chemical attacks, including those that may promote the growth of mold and mildew. As a result, FRP pultrusions are commonly used in environments where moisture and humidity are present, such as bathrooms, swimming pools, and outdoor applications. However, it is important to note that while FRP is resistant to mold and mildew, it is not completely immune. In certain extreme conditions, where moisture levels are consistently high and proper maintenance is neglected, mold and mildew growth may still occur. Regular cleaning and maintenance are recommended to ensure the longevity and resistance of FRP pultrusion profiles to mold and mildew.

- Q: Can FRP pultrusion profiles be used in the water and wastewater treatment industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the water and wastewater treatment industry. FRP pultrusion profiles are highly durable, corrosion-resistant, and have excellent mechanical properties, making them suitable for various applications in the water and wastewater treatment industry. One of the main advantages of FRP pultrusion profiles is their resistance to corrosion. Water and wastewater treatment facilities often deal with aggressive chemicals, high humidity, and corrosive environments. Traditional materials like steel or wood may deteriorate and require frequent maintenance or replacement. However, FRP pultrusion profiles are specifically designed to withstand harsh conditions without corrosion, ensuring long-term performance and reducing maintenance costs. Additionally, FRP pultrusion profiles offer excellent strength-to-weight ratio, making them ideal for structural applications in water and wastewater treatment facilities. They can be used as walkways, handrails, grating, ladders, and other structural components. The lightweight nature of FRP profiles allows for easy installation and minimizes the load on the supporting structures. Furthermore, FRP pultrusion profiles are non-conductive, providing an added safety benefit in water and wastewater treatment facilities. This property is particularly important when dealing with electrical equipment or applications near water sources, reducing the risk of electrical hazards. Moreover, FRP pultrusion profiles can be customized to meet specific design requirements, including different shapes, sizes, and colors. This flexibility allows for greater design freedom, ensuring that the profiles can be tailored to fit the specific needs of water and wastewater treatment projects. Overall, the use of FRP pultrusion profiles in the water and wastewater treatment industry offers numerous advantages, including corrosion resistance, high strength, lightweight, non-conductivity, and design flexibility. These qualities make FRP profiles a reliable and cost-effective choice for various applications in this industry.

- Q: What are the load-bearing capabilities of FRP pultrusion profiles?

- The load-bearing capabilities of FRP pultrusion profiles vary depending on the specific profile design and the type of reinforcement used. However, FRP pultrusion profiles are known to have high strength-to-weight ratios and can generally handle heavy loads. They are often used in structural applications where strength and durability are important factors.

- Q: What are the quality control measures for FRP pultrusion profiles?

- The quality control measures for FRP pultrusion profiles typically include visual inspection, dimensional checks, mechanical testing, and material analysis. Visual inspection ensures that the profiles are free from any visual defects such as cracks, voids, or surface imperfections. Dimensional checks verify that the profiles meet the required specifications and tolerances. Mechanical testing involves conducting various tests like flexural, tensile, and impact testing to ensure the profiles meet the required strength and performance criteria. Material analysis examines the composition and properties of the raw materials used in the pultrusion process to ensure they meet the desired standards. Overall, these quality control measures help ensure the consistent and reliable performance of FRP pultrusion profiles.

- Q: Are FRP pultrusion profiles resistant to fire?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to fire. The composition of FRP includes a resin matrix and reinforcing fibers, such as fiberglass or carbon fiber, which provide excellent fire resistance properties. The resin matrix used in FRP typically has a high flame resistance rating, and the reinforcing fibers do not burn easily. As a result, FRP pultrusion profiles have a high ignition temperature and are inherently self-extinguishing, meaning they will not continue to burn once the flame source is removed. Additionally, FRP pultrusion profiles do not release toxic fumes or smoke when exposed to fire, making them a safer alternative to traditional materials like wood or steel. However, it is important to note that the fire resistance of FRP pultrusion profiles can vary depending on the specific resin formulation and reinforcement material used.

- Q: What are the typical lifespan of FRP pultrusion profiles?

- The typical lifespan of FRP pultrusion profiles can vary depending on various factors such as the specific application, environmental conditions, and maintenance practices. However, on average, FRP pultrusion profiles can have a lifespan ranging from 20 to 50 years.

- Q: Are FRP pultrusion profiles resistant to UV degradation?

- Yes, FRP pultrusion profiles are generally resistant to UV degradation. Pultrusion profiles made from fiberglass reinforced plastic (FRP) are manufactured using a combination of resin and glass fibers. The resin used in the manufacturing process is typically formulated to provide resistance to UV radiation. This UV resistance helps to protect the FRP pultrusion profiles from the harmful effects of prolonged exposure to sunlight. FRP pultrusion profiles have been extensively tested and have demonstrated excellent resistance to UV degradation. They are commonly used in outdoor applications where they are exposed to sunlight, such as in construction, infrastructure, and marine industries. UV resistance ensures that the FRP pultrusion profiles maintain their structural integrity, color, and aesthetic appearance over an extended period of time. However, it is important to note that the level of UV resistance may vary depending on the specific formulation of the resin used in the manufacturing process. Different manufacturers may use different resins with varying levels of UV stabilizers. It is recommended to consult with the manufacturer or supplier to ensure that the specific FRP pultrusion profiles being used are designed to withstand the UV conditions of the intended application. Regular maintenance and periodic inspection of the FRP pultrusion profiles are also important to ensure their long-term UV resistance. This may include cleaning, applying protective coatings, or using UV-blocking additives if necessary. By taking these precautions, the UV resistance of FRP pultrusion profiles can be further enhanced, ensuring their durability and longevity in outdoor environments.

- Q: Do FRP pultrusion profiles have any limitations or drawbacks?

- Yes, FRP pultrusion profiles do have certain limitations and drawbacks. One limitation is that FRP pultrusion profiles have lower stiffness compared to traditional materials like steel or aluminum. This means that they may not be suitable for applications that require high structural rigidity or heavy loads. Another limitation is that FRP pultrusion profiles are prone to creep, which is the gradual deformation of the material under a constant load over time. This can negatively affect the long-term performance and durability of the profiles, especially in applications where they are subjected to sustained stress. Additionally, FRP pultrusion profiles are generally more expensive to produce compared to traditional materials. The manufacturing process involves pultruding continuous fibers through a resin matrix, which requires specialized equipment and expertise. This can result in higher production costs, making FRP pultrusion profiles less cost-effective for certain applications. Furthermore, FRP pultrusion profiles are generally not suitable for high-temperature applications. The resin matrix used in their production can degrade or soften at elevated temperatures, limiting their use in environments where thermal resistance is critical. Lastly, FRP pultrusion profiles may have limited design flexibility compared to other materials. The pultrusion process typically produces profiles with constant cross-sections and limited geometric complexity. This can restrict their use in applications that require intricate shapes or customized designs. Despite these limitations and drawbacks, FRP pultrusion profiles offer several advantages such as high strength-to-weight ratio, corrosion resistance, and electrical insulation properties. It is important to carefully consider the specific requirements of the application before opting for FRP pultrusion profiles.

Send your message to us

FRP Pultrusion Profiles for Carwash Floor New Style

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords