FRP Roofing Panel - Custom Design Corrugated Plastic Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

Fiberglass corrugated sheet is usually used in construction site as protecting facility. It is dagarous for workers in building site since you never know if there is something hard drop down from the high area. So corrugated sheet is installed for preventing the stuff dropping down to hurt people.

FRP GRP Fiberglass Glassfiber Corrugated Roofing is a patent of our company, not like other FRP products, it is produced without yarn, instead, we use mat only. Therefore, the corrugated sheet is more strong in both horizontal and vertical direction.

FEATURES

1). Light Transmission: The light transmission of FRP roof sheet is between 3%-85%. Light through FRP corrugated sheet scatters and is mild. It will not form a light so as to make the indoor brighter.

2). Weather resistant: The UV agent mixing in the corrugated sheet, which can truly resist the damage of ultraviolet ray, which can truly resist the damage of ultraviolet ray.

3). Flame retardant: B1 grade.

4). Anti-corrosion: It resists chemical corrosion and its life span is over 3 times longer than zinc panel.

5). Water proof:100% water proof.

6). Impact capacity: resist impact, tensile and hardly breakable.

7). Light weight: the weight is light, etc

SPECIFICATION

Name: | FRP Roofing |

Material: | Fiberglass |

Width: | 880mm/1050mm |

Effective width: | 800mm/960mm |

Wave length: | 160mm |

Wave height: | 30mm |

Pitch: | 220mm |

Thickness: | 3/2.5mm |

Length: | Customized but must be a multiple of wave pitch |

Color: | Purplish Red, Brick Red, Grey, Green, Blue or customized |

Application: | House, villa, pavilions, industrial plants, large warehouses, supermarkets, stadiums etc |

MOQ: | 1000 Square meter |

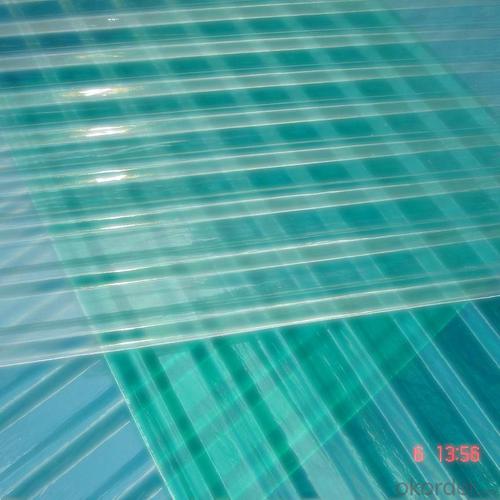

PICTURES

- Q: Can FRP roofing panels be installed on both residential and commercial buildings?

- FRP roofing panels have the capability to be installed on residential and commercial buildings alike. Their versatility enables usage in multiple applications, including roofing. With their lightweight composition, durability, and exceptional resistance to weathering, UV radiation, and corrosion, FRP roofing panels are an ideal selection for both residential and commercial structures. Furthermore, the availability of FRP panels in diverse colors, shapes, and sizes permits customization to accommodate various architectural styles and design preferences.

- Q: Can FRP roofing panels be used for universities?

- Yes, FRP roofing panels can be used for universities. FRP (Fiberglass Reinforced Plastic) roofing panels are lightweight, durable, and resistant to corrosion, making them suitable for various applications, including universities. They provide excellent weather protection, low maintenance requirements, and can be customized to fit different architectural styles. Additionally, FRP panels can offer energy efficiency benefits by reducing heat transfer, enhancing insulation, and allowing the integration of natural lighting.

- Q: Can FRP roofing panels be used for solar panel installations?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can indeed be used for solar panel installations. FRP panels are known for their durability, thermal stability, and resistance to corrosion, making them suitable for supporting solar panels. They are lightweight yet strong, which makes installation easier and reduces the load on the roof structure. Additionally, FRP panels have excellent UV resistance, which is crucial for protecting the underlying solar cells from sun damage. The smooth surface of FRP panels also aids in the efficient performance of solar panels by reducing dirt buildup and facilitating self-cleaning. Overall, FRP roofing panels are a reliable and cost-effective choice for supporting solar panel installations.

- Q: Can FRP roofing panels be installed on metal structures?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be installed on metal structures. FRP roofing panels are lightweight and durable, making them suitable for various applications including metal structures. They can be easily installed on metal roofs using various methods such as screwing, nailing, or using adhesive. FRP panels provide excellent resistance to corrosion, UV rays, and extreme weather conditions, which makes them a popular choice for industrial and commercial buildings. Additionally, their translucency allows natural light to enter the structure, reducing the need for artificial lighting. Overall, FRP roofing panels are a versatile and practical option for metal structures.

- Q: Can FRP roofing panels be installed over an existing roof?

- Yes, FRP roofing panels can be installed over an existing roof. This can be a cost-effective solution as it eliminates the need for removing the old roof and reduces labor and disposal costs. However, it is important to ensure that the existing roof is structurally sound and free from any damage or leaks before installing the FRP panels. Additionally, proper installation techniques and considerations should be followed to ensure a secure and long-lasting roof.

- Q: Are FRP roofing panels fire-resistant?

- Yes, FRP roofing panels are fire-resistant.

- Q: Can FRP roofing panels be used for loading docks or truck shelters?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for loading docks or truck shelters. FRP panels are known for their durability and strength, making them suitable for heavy-duty applications such as loading docks and truck shelters. They are resistant to corrosion, impact, and weather conditions, making them a reliable choice for outdoor structures. Additionally, FRP roofing panels are lightweight, which makes installation and maintenance easier. They are also available in various sizes and colors, allowing for customization to fit specific requirements. Overall, FRP roofing panels are a cost-effective and long-lasting solution for loading docks and truck shelters.

- Q: Are FRP roofing panels suitable for schools?

- Yes, FRP roofing panels are suitable for schools. They are durable, lightweight, and offer excellent resistance to weathering, UV rays, and chemicals. Additionally, FRP panels are cost-effective, easy to install, and require minimal maintenance. These qualities make them an ideal choice for schools looking for a long-lasting and reliable roofing solution.

- Q: Can FRP roofing panels be used for garages?

- Indeed, garages can utilize FRP (Fiberglass Reinforced Plastic) roofing panels. Due to their lightweight nature, durability, and resistance to corrosion, FRP panels prove to be suitable for a range of purposes, garages included. These panels find widespread usage in residential and commercial garage settings due to their capacity to endure severe weather and offer superb insulation. Moreover, the installation process for FRP panels is effortless, and they necessitate minimal upkeep, rendering them an economical option for garage roofs.

- Q: Are FRP roofing panels resistant to warping or sagging due to heat?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are known for their high resistance to warping or sagging due to heat. The composition of FRP panels includes fiberglass reinforcement, which provides exceptional strength and stability even under high temperatures. This reinforcement helps prevent the panels from warping or sagging, ensuring their long-term durability and performance. In addition to the fiberglass reinforcement, FRP panels are also designed to have low thermal expansion properties. This means that they have minimal expansion or contraction with temperature changes, reducing the chances of warping or sagging. The panels are engineered to withstand the heat and maintain their shape and structural integrity, making them a reliable choice for roofing applications. It is worth noting that while FRP panels are resistant to warping or sagging due to heat, proper installation and maintenance are crucial to ensure their longevity. Following manufacturer guidelines and regularly inspecting and maintaining the roof will help maximize the performance and lifespan of the FRP roofing panels.

Send your message to us

FRP Roofing Panel - Custom Design Corrugated Plastic Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords