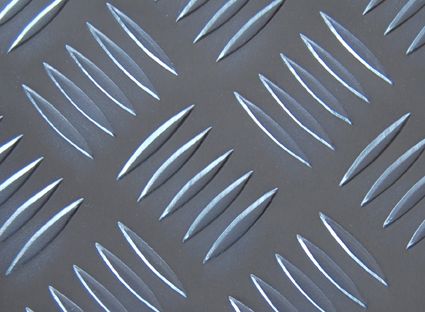

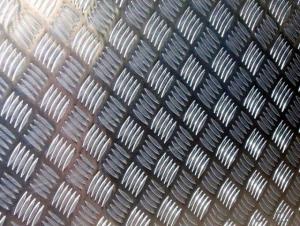

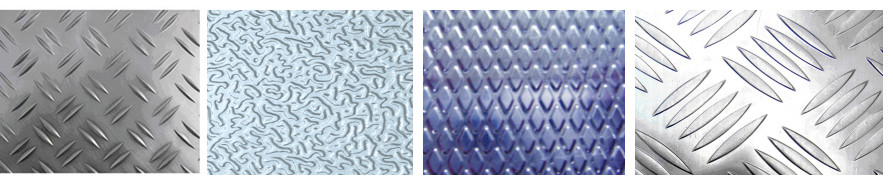

Foam Core Aluminum Sheets - 3003 3004 5052 5754 Five Bar/Diamond Aluminum Checker Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum checkered sheet / plate 3003

1. Alloy: 3003

2. Temper: O-H112

3.Ridge Length: 38mm; Ridge height:0.8-1.2mm

4.Thickness: 1.0-6.0mm

5.Width: 500-2300mm

6.Length: 500-10000mm

7.Main application:

1)Transport vehicles

2)Industrial sheds

3)Fabrication industry

Chamical Components of 3003

Manganese (Mn) | Silicon (Si) Max | Copper (Cu) Max | Iron (Fe) | Zinc (Zn) | Aluminum (Al) |

1-1.5 | 0.6 | 0.2 | 0.7 | 0.15-0.35 | Remainder |

Mechanical Pproperties

Tensile Strength (PSI) | Yield Strength (PSI) | Elongation in 2" |

22,000 | 21,000 | 10 |

Packaging & Delivery

| Packaging Details: | 20-30 days |

| Delivery Detail: | Export standard, covering with plastic film, packed with wood |

FAQ:

Q1.Are you factory or trading company?

A1.We are factory with export rights.

Q2.How many workers in your company?

A2.Around 100-150.

Q3.How long have you been in this product?

A3:More than 10 years.

Q4.What’s your main markets?

A4. Southeast Asia, Mid East, South America ,Africa, Eastern Europe

Q5.What's the minium quantity(MOQ)?

A5.2 Metric tons

Q6.How long is shipping time?

A6.Depending on your quantity normally 15-30 days..

Q7.How do you guarantee the quality?

A7.Professional workers and advanced equipment, all according to the quality standard and client request. QC will check the quality before packaging.

Q8.Do you have after sale service?

A8.Yes.Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: Can aluminum sheets be used for cookware?

- Yes, aluminum sheets can be used for cookware. Aluminum is a popular choice for cookware due to its excellent heat conductivity and lightweight nature. However, it is often used as a core material with other coatings or layers added to enhance its durability and prevent chemical reactions with acidic foods.

- Q: What is the typical weldability of aluminum sheets?

- Aluminum sheets are widely recognized for their exceptional weldability, thanks to their low melting point and excellent thermal conductivity. Various welding techniques, including TIG (tungsten inert gas), MIG (metal inert gas), and even spot welding, can easily be employed to join aluminum sheets. The weldability of these sheets can be further improved by utilizing specialized filler materials exclusively designed for aluminum welding. Nevertheless, it is crucial to acknowledge that the weldability may vary depending on factors such as the alloy composition, thickness, and surface condition of the aluminum sheet.

- Q: Are aluminum sheets suitable for electrical conductors?

- Aluminum sheets are indeed suitable for electrical conductors. They are frequently employed as conductors in a variety of electrical applications due to their remarkable conductivity, lightweight nature, and relatively low cost in comparison to metals such as copper. With approximately 61% of copper's conductivity, aluminum serves as an efficient conductor for most electrical purposes. Power transmission lines, electrical wiring, bus bars, and numerous other electrical components commonly utilize aluminum sheets. However, it is crucial to acknowledge that aluminum possesses higher resistance than copper, necessitating larger cross-sections to carry the same current. Additionally, caution must be exercised to prevent overheating when employing aluminum sheets as electrical conductors, as they have a lower melting point than copper.

- Q: Can aluminum sheets be welded?

- Indeed, welding aluminum is a possibility. Aluminum, being a versatile material, lends itself well to welding through the utilization of different techniques like Tungsten Inert Gas (TIG) welding, Metal Inert Gas (MIG) welding, and Gas Metal Arc Welding (GMAW). However, it is important to note that welding aluminum requires special considerations due to its unique properties in comparison to other metals. Aluminum possesses a low melting point and high thermal conductivity, necessitating a higher heat input and faster welding speed when compared to other metals. Additionally, there is the swift formation of aluminum oxide on the surface, which mandates the removal of this oxide layer prior to welding. To ensure a proper weld quality, specialized welding techniques such as alternating current in TIG welding or the usage of a spool gun in MIG welding are often employed. All in all, with the correct techniques and equipment, aluminum sheets can indeed be welded successfully, making it a favored choice in industries including automotive, aerospace, and construction.

- Q: Are 101 aluminum sheets suitable for cryo-treating applications?

- Indeed, cryo-treating applications can benefit from the utilization of 101 aluminum sheets. Cryo-treating encompasses the practice of exposing materials to extremely low temperatures to enhance their strength, durability, and resistance to wear. 101 aluminum, being a commercially pure alloy, boasts exceptional corrosion resistance and favorable mechanical properties. It can endure cryogenic temperatures without experiencing considerable strength degradation or any adverse consequences. As a result, the application of 101 aluminum sheets in cryo-treating endeavors can effectively yield desired advantages and augment performance.

- Q: Are the aluminum sheets suitable for manufacturing aircraft interiors?

- Yes, aluminum sheets are highly suitable for manufacturing aircraft interiors. Aluminum is a lightweight and durable material that offers excellent strength-to-weight ratio, making it ideal for aviation applications. It is resistant to corrosion, easy to fabricate, and can be easily formed into various shapes and sizes required for aircraft interiors. Additionally, aluminum sheets can be treated with coatings or finishes to meet specific design and functional requirements.

- Q: combines with oxygen with an atomic weight of 16, to form the compound aluminum oxide, how much oxygen would be required to react completely with 54g of aluminum?

- aluminum oxide is Al2O3 , or 2 part Al to 3 part O. 27 grams Al2 *2 / 54 grams Al available = 16 grams of O * 3 / X grams of O solve for X: X = 48 grams of oxygen needed next guy is right....the formula for aluminum oxide is Al2O3..sorry...I readjusted the formula above to show the change

- Q: This question asks for a list of various types of aluminum profiles that are typically used in conjunction with aluminum sheets.

- <p>Aluminum profiles are extruded shapes commonly used with aluminum sheets for various applications. The different types include: 1. Angle profiles, which are used for corners and edges. 2. Channel profiles, suitable for creating channels or frames. 3. T-slot profiles, ideal for modular systems requiring adjustable components. 4. U-channel profiles, used for covering edges and creating frames. 5. H-profiles, often used in structural applications. 6. Flat bar profiles, used for simple straight edges. 7. Round and square tube profiles, used for structural support and design elements. 8. Special profiles, which are custom-made for specific applications. These profiles are chosen based on the structural needs and design requirements of the project.</p>

- Q: Are the aluminum sheets suitable for manufacturing architectural column covers?

- Yes, aluminum sheets are suitable for manufacturing architectural column covers.

- Q: Can the aluminum sheets be custom-cut to specific dimensions?

- Yes, aluminum sheets can be custom-cut to specific dimensions. Aluminum is a versatile material that can be easily manipulated, allowing for precise cutting to meet specific requirements. Whether it is for industrial, commercial, or personal use, aluminum sheets can be tailored to the desired dimensions, ensuring a perfect fit for any project. This customization option allows for greater flexibility and ensures that the aluminum sheets can be used in a variety of applications.

Send your message to us

Foam Core Aluminum Sheets - 3003 3004 5052 5754 Five Bar/Diamond Aluminum Checker Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords