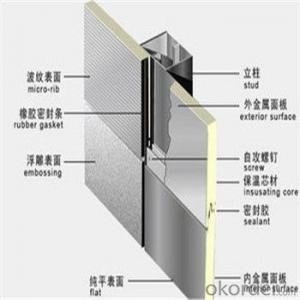

PU Sandwich Wall Panels

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

PU Sandwich Wall Panels

1. Quick Details

| Standard: | Grade: | Place of Origin: | |||

| Brand Name: | Technique: | Surface Treatment: | |||

| Width: | Length: |

2. Packaging & Delivery

| Packaging Detail: | standard seaworthy packing |

| Delivery Detail: | 25 days |

3. Specifications

1.for civil building, car port, roofing, shelters, walk ways, fences & barns.

2. anti-rust.

3.good quality&service.Colored Corrugated Galvanized Steel EPS Sandwich Wall Panels

- Q: These two days is very contradictory, before the decoration and the former contract with the master said the use of the plate is E1 level, the plate is really pulled, but her husband saw a lot of scar on the plate above the wood scar, said the decoration master Cheat him, then simply to the plate company to see, know it is true, but I heard there is a E0 level, and now immediately asked the master replaced by this level

- In China, the State Administration of Quality Supervision, the promulgation of the daily necessities of environmental protection level is not E0 level. E0 is a food grade, which is interpreted as placing the item in water for 24 hours, and the water is still directly drinking the standard. E1 standard is 0-1.5mg / l, so we can see that as long as the formaldehyde emission is positive, it is within the E1 level; EO grade plate only in Europe will have E0 level.

- Q: Do you know the top of the wardrobe?

- The top solid wardrobe is made of high quality plate, special process, moisture resistance, formaldehyde emission meet the E1, E0 environmental standards, with anti-deformation, anti-mildew pest control, anti-acid, anti-scratch, recyclable The use of double-track single pull pulley, the last round of the United States DuPont pu materials, the next round of modified pps material, with wear-resistant, muffler, bearing the strong and so on. With the top of a special top and bottom seal, completely put an end to dust. The top of the wardrobe pulley is the international top of the sliding system, tight seal.

- Q: There are other (some of which are granite): black sands, black and white roots, purple rosewood, green diamond, blue diamond, gold flower stone, beige series, large green flowers, elegant white, jazz white, sesame white and so on. Common thickness is generally 12mm, 15mm, 18mm, 20mm, 22mm, 25mm, 30mm.

- Marble not only look at the size, type, but also look at the board. The thickness of marble is determined by the specific home improvement, usually custom. You can go to WeChat: furniture million and microblogging: furniture million view is a collection of marble, as well as the display of marble in the home improvement applications and effects, may wish to look at my cousin home is here for the decoration That's pretty good

- Q: What is the board made of the board?

- Particleboard: Jilin forest workers Lushui River plate No release of formaldehyde "love home plate" licensed! The The These are the lacquer, are to reach the national standard! Is now the market commonly used plate!

- Q: Teach you how to distinguish between the quality of integrated ceiling plate?

- First look at the material of aluminum magnesium plate, you can roughly visualize the thickness of the integrated ceiling plate, the household is generally around 0.7mm, the project for. The international so now that the provisions, if beyond this range, then it is not the material of magnesium aluminum, because the cost of magnesium and aluminum is relatively high, some businesses in order to seek profits to participate in the other, other materials, but this , Then the flexibility of the plate on the big discount.

- Q: What is love board?

- AIG is the Austrian Group of Agrites FRITZ EGGER GMBH Co. is located in 17 factories in Europe, the production of man-made sheet, environmental protection level to the European E1 level. The Aige plate substrate is covered with a layer of special dipping treatment, with anti-characterization, acid and alkali surface, is widely used in plate furniture and kitchen furniture, English referred to as MFC. ??????? The love plate is selected from coniferous trees grown in the continental margin of the European continent. The love grid overcomes the shortcomings of natural wood and has physical properties that are not easily deformed and stable. Ai grid is a kind of natural logs by cutting, crushing, high temperature and pressure made of a more suitable for furniture production and use of the plate.

- Q: Novice: stainless steel plate calculation and weighing what is the meaning? more specific

- Stainless steel plate calculation and weighing the meaning of stainless steel through the length of the width and wall thickness using the formula to calculate the weight of stainless steel. The pounds are rated directly to the scales that weigh the stainless steel. Stainless steel can be used as a reference. The actual delivery is subject to weight. In fact, it should be said that the price of pounds than the expensive calculation Because the weight of the calculation will be heavier than the actual weight. Probably the actual: 1: 0.92 Attached to the formula: Stainless steel square tube calculation formula: (length + width -2 times wall thickness) * wall thickness * 0.0158 = kg / m Where the length, width, respectively, refers to the long side of the square tube and short side, the unit is mm. Stainless steel tube calculation formula: (diameter - wall thickness) × wall thickness × 0.02491 = kg / m The unit is in millimeters. The above weight is for 304 stainless steel. Can be used as a reference. The actual delivery is subject to weight.

- Q: What is the quality of the board?

- The use of environmental protection factor is higher than the national standard 18mm thickness of the MDF, and the new PVC louver with a different from the general wood sheet of polymer synthetic fiber material, after 200 degrees Celsius Of the high temperature without plastic hot veneer treatment, completely free formaldehyde release. This ensures that the production of "starting line" to reduce the formaldehyde content. The quality of formaldehyde is less than or equal to 1.5mg / L, and the formaldehyde content of E1 grade (national mandatory standard) is less than or equal to 1.5mg / L

- Q: Comparison of fire and water of the plate

- Solid wood is the best, the most upscale

- Q: How to degrease the wood

- Catalytic polymerization Under certain conditions, α and β - pinene will produce polymerization, the formation of yellow sticky material, so that it is fixed or associated with wood, such as aluminum chloride, heme, bleach, tested proved to be effective But the most commonly used boron trifluoride, the boron trifluoride alcohol solution applied to the surface of the plate, it will change the composition of the resin in the terpene, α and β - pinene can be converted into less volatile or Non-volatile, sticky, non-flowable fractions. Brush the boron trifluoride solution at a concentration of 26% on the surface of the resin to reduce the effect of resin bleed [1]. But this method only Wood surface treatment, the wood within the terpene does not change, will still move to the surface of the resin and produce seepage, so this method is suitable for dry after the low moisture content of wood, in the wood before finishing.

Send your message to us

PU Sandwich Wall Panels

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords