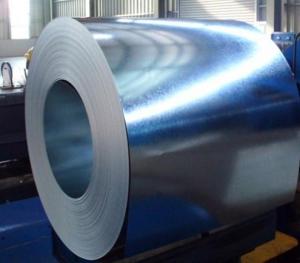

HOT-DIPPED GALVANIZED STEEL COIL

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

HOT DIPPED GALVANIZED STEEL IN COIL

Steel Grade & Standard: JIS G3302 SGHC

Zinc Coating Mass: Z14

Spangle:Regular Spangle

Surface Treatment: Chromated,Unoiled,NonSkinpassed

Coil ID: ABOUT 610mm

Coil Net Weight: 6MTS MAX

- Q: Now a lot of furniture on the market, do not know the solid wood or wood imitation of the wood

- First of all, you can distinguish from the pattern, pure solid wood furniture pattern is no change in the law, and paste leather furniture pattern changes are very regular, such as butterfly-like, or words continue to head, and pure solid wood furniture patterns are irregular The second measure is that you can look at the furniture is not used to start the falcons, falcons are solid wood furniture, one of the necessary technology, the so-called falcon, that is, slot, wood and wood convergence is not glue and nails , But rather like a child to play the same building blocks, so that together, this is why the reasons for environmental protection of solid wood furniture, and the layout of the furniture is absolutely impossible to use frying craft third trick, generally better solid wood furniture, in addition to In addition to the structure of the falcon, there should be splicing technology, splicing is divided into two kinds, tooth and then flat, as the name suggests, tooth connection, is the two selected wood, both ends are playing like a tooth-like teeth, and then two pairs Together, this is the tooth connection, if there are teeth of the furniture, take the wardrobe door, the door inside and outside the tooth interface must be on the fourth move, solid wood furniture should generally be round circle The design of the corner, because only the wood, in order to withstand the pressure to cut into a circular, the layout is not possible

- Q: How to maintain glasses glasses frames

- As the glasses frame has many advantages, but also with the shortcomings is very easy to deformation. Usually maintenance to do: hands picking, once the deformation, please promptly to the eye shop to adjust.

- Q: Furniture board specifications four eight feet What is the meaning of that: 4 * 8

- Consistent with the specifications of stainless steel plate, 4 * 8 four eight feet that is 1219mm * 2438mm It is 1 meter 22 * 2m 44

- Q: 1, if the nose is a metal support, you can hand to the middle of breaking off.

- 1, if the nose is a metal support, you can hand to the middle of breaking off. 2, if the whole into a whole is plastic, nasal care will not be deformed. It must be attached to the lens and the lens between the screws too loose, two mirror feet breaking too open, you can tighten the screw tight. 3. If you have a small wedge, you can tighten the screws on both sides of the frame, it is recommended not to break the glasses to the inside, because the improper grasp of the words easily broken In addition to the optical shop can have a special person will help you tune, of course, is generally selling glasses.

- Q: The production of melamine sheet

- Melamine board Melamine board, full name is melamine impregnated film paper facing wood-based panel. Is to put the paper with different colors or textures into the melamine resin adhesive soak, and then dry to a certain degree of curing, will be paved in the particleboard, medium density fiberboard or hard fiber board surface, made by hot pressing plate. In the production process, usually by the combination of several layers of paper, the number of depending on the number of purposes. General sub-surface paper, decorative paper, covered paper and the underlying paper and other components. Surface paper, is placed on the top of the decorative plate, from the role of decorative paper, so that after heating and pressing the surface of the plate highly transparent, hard surface hard wear, this paper requires good water absorption, white and clean, transparent after dipping. Decorative paper, that is, wood grain paper, is an important part of decorative panels, with a background or no background, printed on a variety of patterns of decorative paper, placed under the surface paper, mainly from the decorative effect, this layer requires paper Has good hiding power, impregnation and printing performance. Cover paper, also known as titanium white paper, generally in the manufacture of light decorative panels, placed under the decorative paper to prevent the underlying phenolic resin through to the surface, its main role is to cover the surface of the substrate color spots. Therefore, require a good coverage. The above three kinds of paper were soaked with melamine resin. The bottom of the paper, is the decorative board of the base material, the board from the mechanical properties of the role is impregnated with phenolic resin by drying, the production can be used according to the thickness of the plate or to determine a number of layers.

- Q: Teach you how to distinguish between the quality of integrated ceiling plate?

- Integrated ceiling plate classification Rolling board: resistant to decay, resistant to powder, corrosion resistance; Nano-board: resistant to decay, more self-cleaning, anti-fumes; Covered board: anti-fumes, wear-resistant, moisture-proof, feel good, color and more; Drawing board: high-quality substrate, imported diamond cloth wheel surface pull pattern, a variety of chemical treatment, sound insulation, corrosion, board shape effect is good, bright color; Anodized plate: temperature, the surface does not fall off, 20 years do not fade, scratch, wear, easy to scratch, anti-static, anti-interference, anti-electromagnetic radiation, anti-ultraviolet, no dust, The

- Q: What are the characteristics of spruce plate?

- Strong pine wood] to answer your questions about wood! ?? Spruce, also known as European white pine, its fine texture straight, material stability, not easy to deformation cracking, strong resistance, while easy to planing, planing the surface after the smooth, bright, can absorb paint and colorants, and Easy to glue. It itself has a soft color, fine texture and natural texture is very natural into the furniture design, showing a simple original beauty. Spruce has a variety of advantages and uses a wide range, has been hailed as "the Nordic green diamond." ????? Main use: furniture components, housing ceiling, decorative keel, floor, shutters, cabinets, wall panels, musical instruments, organ tubes, boxes, wooden barrels, joinery, cutting wood, sleepers, building structural materials, Bridges and other timber.

- Q: Ecological board and imported incense board which light fastness

- Ecological board and imported incense board which is more light, first of all we have to know that the ecological board is a man-made sheet, he is made of an environmentally friendly materials, and incense wood is a plate, from the light Aspect, it is certainly cooler wood.

- Q: Are plates p2 and e0 almost?

- In the purchase process, as long as optimistic about the level of formaldehyde release board on the line. E0 best, E1 times, E2 has been rarely used. Southeast wood manufacturers have super E0 board, formaldehyde release even less, but also by the United States California certification p2 plate. CAPB P2 level is higher

- Q: Home decoration need to do wardrobe, what plate is the most environmentally friendly?

- Recommend you go to OKorder Long crystal, where the home decoration is very good, especially in the environmental awareness of today's popular people welcome!

Send your message to us

HOT-DIPPED GALVANIZED STEEL COIL

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords