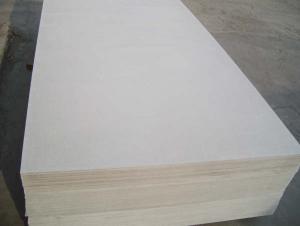

calcium silicate interior board

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 120000pcs pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,LUTAI calcium silicate board is a stable performance and light weight

building&decoration board used siliceous and calcareous materials as major and natural fiber reinforced ,with the process of pulping ,emulsion, forming ,pressurization ,autoclaving, drying and surface treatment .

Thickness : 4.5mm-30mm

Size :1200*2400mm, 1220*2440mm, any size that u need .

Surface : 40#-120# sanding surface , polished surface , tapered edge .

2,Product Characteristics

Materials: Tombermorite crystals , natural fiber…….

Fire-proof : A-class incombustible (GB8624-1997)

Incombustibility: 240 minutes (GB/T9978-1999)

Density: 1.2-1.4g/cm3

Water content ratio:≤10%

Swelling ratio:≤0.45%

Shrinking ratio:≤0.45%

Anti-being strength:≥12MPA 、

Frost resistance : Don’t appear cracking and delamination after 25 cycles of freezing and thawing . (GB/T7019-1997)

Radioactivity: Standard of GB6566-2001 (A-class Decoration Materials)

3,Recommend Application:

Partition board,suspended ceilings , interior panel, exterior panel .

- Q: I am married to decorate the house, and to do two large wardrobe, a bookshelf, a TV cabinet, ask you what wood board is better, very grateful !!!

- Large wardrobe and bookcase with blockboard, about 80 pieces. TV cabinet with a paint-free board on the line.

- Q: How about Tiantuo plate

- How to buy plate (1) whether it is environmentally friendly. According to the provisions of the indoor building materials formaldehyde emission must be less than or equal to 1.5mg / l, if more than 5mg / l is exceeded. (2) wood moisture content. When the wood moisture content is higher than the equilibrium moisture content of the environment, the wood will dry shrink, otherwise it will absorb moisture expansion. The main cause of wood cracking and deformation is that the moisture content is too high or too low. (3) Do not just cheap. Low-priced materials are usually sold and crushed and formaldehyde seriously exceeded the material, should be to the regular market to buy, it is best to buy a brand of materials. (4) the purchase of wood flooring when the tree species do not have to worry about the name, the election is the most important dealer.

- Q: 1, if the nose is a metal support, you can hand to the middle of breaking off.

- 1, if the nose is a metal support, you can hand to the middle of breaking off. 2, if the whole into a whole is plastic, nasal care will not be deformed. It must be attached to the lens and the lens between the screws too loose, two mirror feet breaking too open, you can tighten the screw tight. 3. If you have a small wedge, you can tighten the screws on both sides of the frame, it is recommended not to break the glasses to the inside, because the improper grasp of the words easily broken In addition to the optical shop can have a special person will help you tune, of course, is generally selling glasses.

- Q: My family ready to decorate, my friend recommended to me Lili She Lug plate, I do not know how this brand?

- Standard plate manufacturing process, the original addition to aldehyde glue, automatic digital kiln drying sterilization technology, greatly enhance the performance of the plate, the quality is more stable. Strict implementation of ISO9001: 2008 quality management system standards, each batch of products for sampling, to ensure that the product qualified rate of 99.9%.

- Q: Will the 2017 plate 10 brand quality how?

- Ranked by quality, the New Zealand Pavilion is a well-deserved first. New Zealand Chilean plate benefited from New Zealand's unique island climate, and in the case of the ever-decreasing natural forests in the world, New Zealand Wood has grown well as a sustainable renewable resource. Zhige plate selection of trunk high, light color, solid wood, very suitable for furniture manufacturing and a variety of decorative wood applications.

- Q: What is the plate

- Usually made of standard size flat rectangular building material board, as a wall, ceiling or floor components. Also refers to the forging, rolling or casting made of metal plate. 1. Usually made of standard size flat rectangular building materials (such as plywood, metal plate, concrete slab, plastic plate), as a wall, ceiling or floor components. Thick rough board. 3. Forging, rolling or casting of metal plates. 4. Plate are: Daxin board density board decorative panels three PCT board five PCT board 9 PCT board 12 PCT board waterproof board gypsum board cement board paint plate paint plate (Reference: Ningbo love good green wood cans Limited) The logs are made of logs and the material of the square. Width of more than three times the thickness of the "plate"; width less than three times the thickness of the rectangular wood called "square material." Is a furniture manufacturing, civil engineering and other commonly used materials.

- Q: Cedar Blockboard Good and Pure Wooden Plate Which is good?

- See you use the scope of what to use, but relatively do not consider the price or solid wood is good. Blockboard is a solid wood board joinery board, also known as Daixin board, the logs cut into pieces, stitching into a core, Because the main are solid wood, so many sales staff will be said to be environmentally friendly sheet, in fact, like a large core board is containing the man-made adhesive sheet. Three hydrogen ammonia plate is the MDF, with this material to do the surface of the plate are called three hydrogen ammonia plate, and the substrate is the same, and MDF, particleboard and so can be made of three hydrogen ammonia plate. Solid wood panels are durable, natural lines, mostly natural wood unique aroma, with good hygroscopicity and permeability, good for human health, does not cause environmental pollution, is the production of high-grade furniture, decoration of the high-quality housing plate. Some special materials (such as beech) solid wood board or the manufacture of buttocks, precision instruments ideal material.

- Q: Meet the ROHS standard PCB board which?

- Pmma is in line with the ROSH standard but you are not used

- Q: Sound insulation, then, with which plate is good?

- Noise barriers / special insulation board: double-sided UV solid board, three boards, X board series ???Three layers: thickness 10-20mm, the maximum width of 2100mm, length 6000mm. (Can be customized) There are ten colors available (red, black, lake blue, blue, transparent, opal, advertising white, grass green, green, brown) X-type hollow board: thickness 8-20mm, the maximum width of 2100mm, length 6000mm. (Can be customized) Sound insulation: good sound insulation, can effectively reduce the noise, in the international are the preferred material for highway noise barriers. High strength: polycarbonate sunshine board strength, high security, "not broken glass" and "ring steel" reputation, is the bulletproof glass of high quality materials. Good weather resistance: the use of international advanced production technology, the board evenly distributed high concentrations of UV co-extruded layer, can effectively absorb ultraviolet light, thereby extending the life of the plate. Product Usage: 1. Office buildings, department stores, hotels, villas, schools, hospitals, sports venues, entertainment centers and public facilities of the lighting ceiling. 2. Noise barriers for highways, railways and urban viaducts. 3. Modern plant greenhouse and indoor pool of the sky. 4. Metro entrances, stations, parking lots, shopping malls, pavilions, restrooms, corridors of the canopy. 5. Bank anti-theft counters, jewelry store anti-theft window, police riot shield. 6. The airport, the factory safety lighting materials. 7. Advertising light box panel, advertising display card. 8. Household, office indoor interval, pedestrian access, guardrail, balcony, shower room sliding door.

- Q: Many types of flooring, which OKorder is suitable for several floor plate?

- Ficus aurantium, Indian eggplant, ash wood, round beans, two wings beans, oak (white oak) Pineapple (small pineapple) Features: heavy, relatively hard. Stability is very good. Affordable choice. Description: The color of dark reddish brown wood, texture dense and strong, with curved curved black wood texture, the island people often used to make piling boat keel and semi-circular bracket. Wood adhering to the fine characteristics of pineapple grid, is a can be used for geothermal and has a variety of color selection of subtropical wood species. Is the ideal alternative to pineapple grid, also known as small pineapple grid. On behalf of the brand: Kyrgyzstan (mid-range), Huaming (old brand of good service), Li Feng (first-line brand) Merlin wood features: heavy, more hard wear, anti-termite moisture. Stability is very good, are cost-effective species, once popular. Indonesia to reduce the cutting prices have an upward trend. Brief introduction: 1, Indian eggplant is growing in the paradise rain forest in the precious tropical hardwood, it takes 80 years to mature, in each hectare virgin forest can only find 1-5 trees.

Send your message to us

calcium silicate interior board

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 120000pcs pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords