Flexible 1M to 4M EPDM Waterproofing Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Waterproof Membrane

1.Product Description

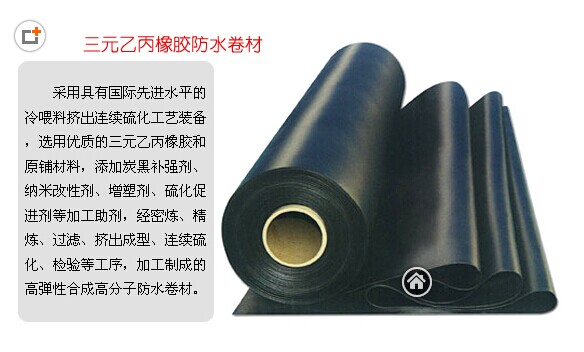

Flexible EPDM Waterproofing Membrane is the modified materials which is widely used at home and abroad in the kinds of roofs, tunnel, basement such sorts of constructions' waterproofing. They are based upon EPDM rubber with modifier, softener and accelerant assistants added to provide flexibility and stability . Through the precise ingredients, mixing, extrusion, rolling, curing processes to made of modified EPDM Waterproofing material with high strength and high flexibility.

2.Features

1. Great tensile strength,long-range elasticity and aging resistant.

2. Excellent heat reisistant and can be used under -70°C~~+110°C .

3.Good anti-corrosion, ultraviolet resistant, root penetration resistance

4.Long life use over 50 years and used longer 100 years or more under the condition of buried in the ground.

5.Light and easy to install.

3.Products Specification

Thickness : 0.3-2.0mm

Width :1m to 4m

Length: 15-100m/roll

Type | EPDM Waterproof Membrane | ||

Material | EPDM Rubber | ||

Thickness | 1.2mm | 1.5mm | 2.0mm |

Weight(kg/m2) | 1.54-1.58 | 1.79-1.83 | 2.25-2.29 |

Size | 1.2m(width) * 20m(length)/roll | ||

Type | Vulcanized & Weldable | ||

Pattern | Non-reinforced(homogeneous) | ||

Packing | 24sqm/roll, with plastic bag | ||

Color | Black | ||

Application | Roof, basement, pond, Lake, steel structure roof, swimming pool, underground, tunnel, etc | ||

4. Product Application:

(1) Roofs, Basement, Toilets

(2) Industrial and civil building waterproofing

(3) Geosynthetic liner for swimming pool, channels, irrigation system

(4) Especially suitable for projects with high requirements in durability, anti-corrosion and deformation

4. Some photos:

- Q: Does a waterproofing membrane require any special considerations for installation in seismic zones?

- Yes, a waterproofing membrane does require special considerations for installation in seismic zones. Seismic activity can cause significant ground movement and structural vibrations, which can potentially compromise the integrity of the membrane. Therefore, it is crucial to select a membrane that is specifically designed and tested to withstand seismic conditions. Additionally, proper installation techniques and materials, such as reinforced membranes and flexible adhesives, should be used to ensure the membrane remains intact during seismic events.

- Q: Are there any specific considerations for installing a waterproofing membrane on wood surfaces?

- Yes, there are several specific considerations when installing a waterproofing membrane on wood surfaces. First and foremost, it is important to ensure that the wood surface is clean, dry, and free from any dirt, dust, or debris. This will help to create a proper bond between the wood and the waterproofing membrane. Additionally, it is crucial to choose a waterproofing membrane that is specifically designed for wood surfaces. There are different types of membranes available, such as liquid-applied membranes or sheet membranes, so selecting the right one is essential. Before applying the membrane, it is advisable to prime the wood surface with a suitable primer. This will help to enhance the adhesion of the membrane and provide a more durable and long-lasting waterproofing solution. It is also important to consider the climate and weather conditions in the area where the wood surface is located. If the area is prone to extreme temperatures or heavy rainfall, it is recommended to choose a waterproofing membrane that can withstand these conditions and provide adequate protection. Furthermore, proper installation techniques should be followed to ensure the membrane is applied correctly. This may involve rolling or brushing the membrane onto the wood surface, as per the manufacturer's instructions. It is crucial to pay attention to details such as seams, corners, and edges to ensure a watertight seal. Regular maintenance and inspection are essential for the longevity of the waterproofing membrane on wood surfaces. It is important to check for any signs of damage, such as cracks or peeling, and address them promptly to prevent water infiltration and potential damage to the wood. In summary, when installing a waterproofing membrane on wood surfaces, it is crucial to prepare the surface properly, choose the right type of membrane, consider the climate and weather conditions, follow proper installation techniques, and perform regular maintenance and inspection. By doing so, you can effectively protect the wood surface from water damage and ensure its longevity.

- Q: Can a waterproofing membrane be used on plywood surfaces?

- Yes, a waterproofing membrane can be used on plywood surfaces. Plywood is a commonly used material for construction, including outdoor projects such as decks and balconies. However, plywood is not naturally waterproof and can be susceptible to moisture damage over time. To protect plywood surfaces from water damage, a waterproofing membrane can be applied. This membrane acts as a barrier, preventing water from seeping into the plywood and causing rot or decay. There are various types of waterproofing membranes available, including liquid-applied membranes, sheet membranes, and peel-and-stick membranes. These membranes are designed to adhere to the surface of the plywood and create a watertight seal. It is important to follow the manufacturer's instructions for proper application and ensure that the plywood surface is clean and dry before applying the membrane. By using a waterproofing membrane, plywood surfaces can be effectively protected from water damage, extending their lifespan and maintaining their structural integrity.

- Q: Does a waterproofing membrane require any specific safety precautions during installation?

- Yes, installing a waterproofing membrane does require specific safety precautions. These may include wearing protective clothing, such as gloves and goggles, to prevent contact with chemicals or materials that may be harmful. It is important to ensure proper ventilation in the installation area to minimize exposure to potentially harmful fumes or vapors. Additionally, following manufacturer's instructions, using proper tools and equipment, and working in a well-organized manner can help prevent accidents or injuries during the installation process.

- Q: Elastomer modified asphalt waterproofing membrane for what purpose? Need to pay attention to a few things?

- First, the quality of waterproof base surface Waterproof base (leveling layer) must be hard, smooth, dry, clean, should not have anti-sand, remove the sharp objects. Waterproof base surface if there are defects, should be done before the waterproof repair, must be painted base treatment agent. Waterproof surface should not have ice, snow or water.

- Q: Is a waterproofing membrane resistant to solvents or chemical spills?

- Yes, a waterproofing membrane is typically resistant to solvents or chemical spills.

- Q: Can a waterproofing membrane be used on asphalt surfaces?

- Yes, a waterproofing membrane can be used on asphalt surfaces. Waterproofing membranes are commonly used in construction and are designed to provide a protective barrier against water infiltration. They are versatile and can be applied to various surfaces, including asphalt. Applying a waterproofing membrane on an asphalt surface can help prevent water damage, increase the longevity of the surface, and protect the underlying structures. It is important to ensure that the waterproofing membrane used is compatible with asphalt and that proper installation techniques are followed to achieve optimal results.

- Q: Does a waterproofing membrane prevent water infiltration through concrete or other building materials?

- Yes, a waterproofing membrane is designed to prevent water infiltration through concrete or other building materials. It acts as a barrier, effectively sealing off the surface and protecting the underlying structure from water damage.

- Q: Can a waterproofing membrane be used for elevator pits and sump pits?

- Elevator pits and sump pits, commonly prone to water leakage and moisture problems, can benefit from the use of a waterproofing membrane. These membranes are designed to resist water penetration and create a barrier against water intrusion, effectively sealing the pits. Materials such as rubberized asphalt, EPDM, or PVC are typically used to construct these membranes, which are then applied to the walls and floors of the pits. The installation of a waterproofing membrane provides protection to the elevator and sump pits, safeguarding them against water damage, including corrosion, mold growth, and structural deterioration. This not only ensures the functionality and durability of the pits but also creates a safe and healthy environment for occupants and equipment. Nevertheless, it is essential to consider the specific requirements and regulations of elevator and sump pit installations, as different jurisdictions may have their own codes and standards that must be adhered to. Furthermore, proper installation and regular maintenance of the waterproofing membrane are crucial to guarantee its effectiveness in preventing water infiltration.

- Q: Does a waterproofing membrane provide any protection against radon gas?

- No, a waterproofing membrane does not provide any protection against radon gas. Radon gas is a radioactive gas that can seep into buildings through cracks and openings in the foundation or walls. While a waterproofing membrane can help prevent water penetration and moisture issues, it does not provide an effective barrier against radon gas. To protect against radon gas, specific radon mitigation measures such as sealing cracks, installing a radon mitigation system, or improving ventilation should be implemented. It is important to consult with radon professionals who can assess the radon levels in your area and provide appropriate recommendations to mitigate the gas.

Send your message to us

Flexible 1M to 4M EPDM Waterproofing Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords