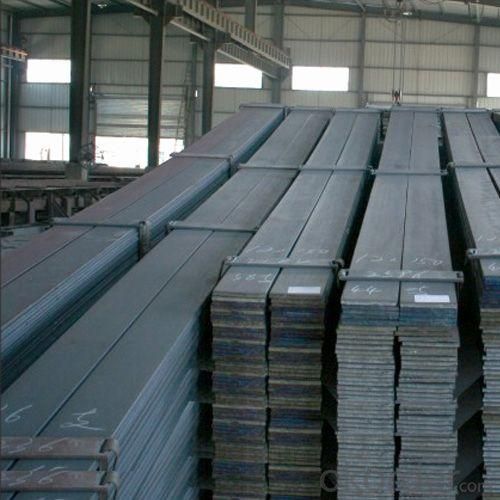

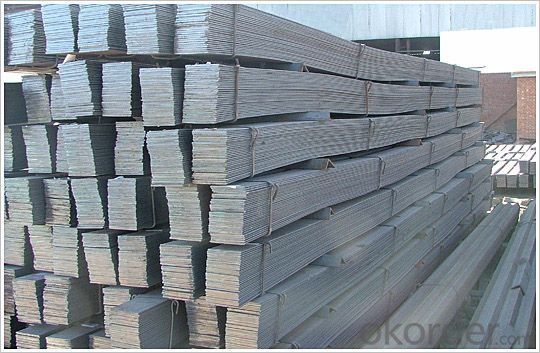

Flat Steel Bar Q235 SS400 A36 Ms Mild Hot Rolled Black Carbon

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Flat Steel Bar Q235 SS400 A36 Ms Mild Hot Rolled Black Carbon at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Flat Steel Bar Q235 SS400 A36 Ms Mild Hot Rolled Black Carbon are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Flat Steel Bar Q235 SS400 A36 Ms Mild Hot Rolled Black Carbon are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

carbon flat steel bar

1.Thickness:1.5mm-14mm

2.Width:10mm-1010mm

3.Grade:Q235, Q345, A36

4. BV verified

Details of carbon flat steel bar

| Name | carbon flat steel bar |

| Standard | AISI, ASTM, BS,DIN,GB,JIS |

| Grade | A36, SS400, Q235, Q345, S235,S275 |

| Dimensions | 1.5mm-14mm |

| Length | 6-12m |

| Technique | carbon flat steel bar |

| Tolerance | As the standard or as your requirement |

| Application | Metal structure, bridge, machiner, shipbuilding industry |

| Certificated | carbon flat steel bar |

| MOQ | 25 tons carbon flat steel bar |

| Delivery | Within 25 days after deposit |

| Payment | T/T or L/C |

Advantage carbon flat steel bar

1. Convenient in construction and save much time and labor

2. High mechanical strength

3. Low price, high quality

carbon flat steel bar specifications

| carbon flat steel bar | |||

Width (mm) | Thickness (mm) | Length (m) | Theoretical Weight (kg/m) |

| 20 | 2.0 | 6/9/12 | 0.31 |

| 20 | 2.5 | 6/9/12 | 0.39 |

| 20 | 2.75 | 6/9/12 | 0.43 |

| 25 | 2.5 | 6/9/12 | 0.49 |

| 25 | 3.75 | 6/9/12 | 0.74 |

| 30 | 2.5 | 6/9/12 | 0.59 |

| 30 | 3.5 | 6/9/12 | 0.82 |

| 30 | 9.75 | 6/9/12 | 2.30 |

| 40 | 3.5 | 6/9/12 | 1.10 |

| 40 | 4.75 | 6/9/12 | 1.50 |

| 40 | 11.75 | 6/9/12 | 3.69 |

| 50 | 2.75 | 6/9/12 | 1.08 |

| 50 | 4.5 | 6/9/12 | 1.77 |

| 50 | 9.75 | 6/9/12 | 3.83 |

| 60 | 5.5 | 6/9/12 | 2.60 |

| 60 | 7.5 | 6/9/12 | 3.53 |

| 60 | 11.5 | 6/9/12 | 5.42 |

| 80 | 5.5 | 6/9/12 | 3.45 |

| 80 | 7.5 | 6/9/12 | 4.71 |

| 80 | 11.75 | 6/9/12 | 7.38 |

| 100 | 3.25 | 6/9/12 | 2.55 |

| 100 | 4.75 | 6/9/12 | 3.73 |

| 100 | 7.5 | 6/9/12 | 5.89 |

| 120 | 9.75 | 6/9/12 | 9.18 |

| 120 | 11.75 | 6/9/12 | 11.07 |

| 150 | 9.75 | 6/9/12 | 11.48 |

| 150 | 11.5 | 6/9/12 | 13.54 |

| 150 | 13.5 | 6/9/12 | 15.90 |

| 160 | 11.75 | 6/9/12 | 14.76 |

| 200 | 9.5 | 6/9/12 | 14.92 |

| 250 | 5.75 | 6/9/12 | 11.28 |

| 340 | 7.75 | 6/9/12 | 20.68 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q: What are the different tolerance levels for steel flat bars?

- The tolerance levels for steel flat bars can vary depending on the specific requirements and standards set by the industry. Generally, the tolerance levels for steel flat bars can range from tight tolerances, where the dimensions must be extremely precise, to standard tolerances, where a small degree of variation is acceptable. It is important to consult the relevant standards or specifications to determine the exact tolerance levels for a particular application.

- Q: How do steel flat bars compare in terms of strength and durability?

- Steel flat bars are known for their exceptional strength and durability. Due to their flat shape, they offer enhanced load-bearing capacities and resistance to bending or warping. Additionally, steel flat bars are highly resilient against external impacts and corrosion. Overall, they are a reliable choice for applications requiring robustness and longevity.

- Q: Can steel flat bars be bent without cracking?

- Yes, steel flat bars can be bent without cracking, as long as the bending process is carried out within the material's specified limits and proper techniques are used.

- Q: How do steel flat bars perform in corrosive or acidic environments?

- Steel flat bars can be susceptible to corrosion in corrosive or acidic environments. The extent of their performance would depend on the type of steel used and any additional protective coatings applied. However, in general, steel flat bars may require regular maintenance and protective measures to prevent or minimize corrosion in such environments.

- Q: Can steel flat bars be used for structural support?

- Yes, steel flat bars can be used for structural support. Steel flat bars are commonly used in construction and engineering projects to provide structural support, especially in applications where high strength and durability are required. They are often used as beams, braces, or supports in buildings, bridges, and other structures. Steel flat bars have excellent load-bearing capabilities and can withstand heavy loads and forces, making them suitable for structural support. Additionally, steel flat bars can be easily welded or bolted together to create larger structural elements, allowing for flexibility in design and construction.

- Q: Are steel flat bars suitable for electrical conductivity applications?

- No, steel flat bars are not suitable for electrical conductivity applications. Steel is a poor conductor of electricity compared to other materials like copper or aluminum. While steel can conduct electricity to some extent, its conductivity is significantly lower than that of metals specifically designed for electrical applications. Therefore, it is recommended to use materials with higher electrical conductivity, such as copper or aluminum, for electrical conductivity applications.

- Q: Are steel flat bars suitable for making electrical enclosures or cabinets?

- Yes, steel flat bars are suitable for making electrical enclosures or cabinets. Steel flat bars offer excellent strength and durability, making them ideal for providing adequate protection and support for electrical components. They can also be easily welded or bolted together, allowing for the construction of custom designs and configurations. Additionally, steel flat bars can withstand various environmental conditions, ensuring the longevity and reliability of the electrical enclosures or cabinets.

- Q: Are steel flat bars resistant to impact or vibration?

- Known for their high strength and durability, steel flat bars exhibit a remarkable resistance to both impact and vibration. This is attributed to the composition of steel and its structural integrity, allowing it to effectively absorb and distribute energy resulting from impacts or vibrations. Consequently, steel flat bars are highly suitable for a wide range of applications in construction, automotive, and industrial sectors where resistance to impact or vibration is of utmost importance. Moreover, the ability of steel to withstand impacts and vibrations ensures the prolonged lifespan of structures and components, mitigating the potential risks of damage or failure.

- Q: Can steel flat bars be galvanized or coated with zinc?

- Yes, steel flat bars can be galvanized or coated with zinc. Galvanization or zinc coating is a common method used to protect steel from corrosion. It involves immersing the steel in a bath of molten zinc or applying a zinc coating onto the surface of the steel. This process creates a protective layer of zinc that acts as a barrier against rust and other forms of corrosion. Galvanized steel flat bars are widely used in various industries, including construction, infrastructure, and manufacturing, due to their enhanced durability and resistance to corrosion.

- Q: What is the bending capacity of a steel flat bar?

- The ability of a steel flat bar to withstand bending forces without breaking or permanently deforming is known as its bending capacity. Several factors, including the steel's dimensions, thickness, composition, the applied load, and the type of bending being performed, influence the bending capacity. Steel flat bars generally have a high bending capacity due to their inherent strength and durability. To determine the specific bending capacity of a steel flat bar, engineers can calculate the maximum bending moment it can withstand before failure occurs. This calculation involves using engineering formulas and principles like the moment of inertia and the steel's yield strength. It should be noted that the bending capacity of a steel flat bar can vary depending on its grade or alloy. Different grades of steel have distinct mechanical properties, such as tensile strength and yield strength, which directly affect their bending capacity. Therefore, considering the specific grade and composition of the steel flat bar is crucial when assessing its bending capacity. Furthermore, the shape and dimensions of the steel flat bar also significantly impact its bending capacity. Wider and thicker flat bars generally have higher bending capacities compared to narrower and thinner ones. This is because the increased cross-sectional area provides more resistance against bending forces. In conclusion, the bending capacity of a steel flat bar is influenced by factors like the grade of steel, dimensions, and applied load. To accurately determine the bending capacity, consulting engineering references or professionals who can perform calculations based on the specific properties of the steel flat bar is recommended.

Send your message to us

Flat Steel Bar Q235 SS400 A36 Ms Mild Hot Rolled Black Carbon

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords