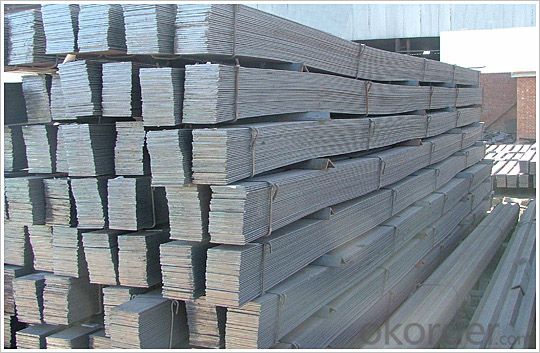

Flat Steel high quality slitting hot rolled q235 black carbon steel flat bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | at mill's standard packing in bundles / as per customer's packing instruction |

| Delivery Detail: | 5 ~ 20 days after receiving the deposit |

Specifications

flat bar

1.all the specifications

2.large quantity

3.best service

4.strict quality control

Type | Flat bar |

Grade: | A36, S235jr, St37-2, SS400, Q235,Q195 |

Standard: | AISI, ASTM, BS, JIS, GB |

Color | Black or galvanized |

Size | 10*1.5-870*12mm |

Payment terms | L/C,T/T, etc. |

Price term | Exw,FOB/CIF/CNF or as required |

Application | Construction; ship building; communication tower,steel grating etc... |

Market | Application for Australia, Southeast Asia,India, Mid-East and African market. |

Packaging Details: | At mill’s standard packing in bundles / as per customer's packing instruction |

- Q: What are the safety precautions when working with steel flat bars?

- When working with steel flat bars, it is important to take certain safety precautions to minimize the risk of accidents or injuries. Some of the key safety measures include wearing personal protective equipment (PPE) such as safety glasses, gloves, and steel-toed boots to protect against potential hazards. Additionally, using appropriate lifting techniques or mechanical aids to handle heavy or large steel flat bars can prevent strain or back injuries. It is also crucial to ensure a well-ventilated work area to minimize exposure to fumes or dust generated during cutting, grinding, or welding processes. Regularly inspecting the flat bars for any defects or damage and properly securing them during transportation or storage is another important safety practice. Overall, following these safety precautions helps ensure a safer working environment when dealing with steel flat bars.

- Q: Can steel flat bars be used in food processing applications?

- No, steel flat bars are not typically recommended for food processing applications due to the risk of contamination and potential chemical reactions with certain food products. Stainless steel is the preferred material for such applications due to its resistance to corrosion and ability to maintain hygiene standards.

- Q: What are the different tolerances for steel flat bars?

- The tolerances for steel flat bars can vary depending on the specific requirements and industry standards. Generally, the most common tolerances for steel flat bars are determined by the American Society for Testing and Materials (ASTM) or the International Organization for Standardization (ISO). The tolerances for steel flat bars typically include dimensions such as width, thickness, and length. These dimensions are specified to ensure that the flat bars meet certain quality standards and can be used effectively in various applications. For width tolerances, the range can vary from as tight as ±0.005 inches (0.13 mm) to as loose as ±0.25 inches (6.35 mm). The specific tolerance is typically determined based on the required precision and application of the steel flat bar. For thickness tolerances, the range can vary from ±0.005 inches (0.13 mm) to ±0.25 inches (6.35 mm). Again, the specific tolerance depends on the desired precision and application. Length tolerances for steel flat bars can range from ±0.125 inches (3.18 mm) to ±1 inch (25.4 mm). This tolerance is crucial to ensure that the flat bars can be accurately cut to the desired length and fit properly in the intended application. It is important to note that these tolerances are just general guidelines and can vary based on the specific standards set by the manufacturer or customer requirements. It is always recommended to consult the relevant industry standards or specifications to determine the specific tolerances for steel flat bars in a particular application.

- Q: Are steel flat bars commonly used in the construction of transportation facilities?

- Steel flat bars are widely utilized in the construction of transportation facilities due to their versatility and strength. They are well-suited for numerous applications in transportation infrastructure, such as framing structures, reinforcing concrete, and serving as support beams in bridges and highways. The exceptional load-bearing capacity and resistance to bending that steel flat bars offer make them an excellent choice for constructing transportation facilities capable of withstanding heavy loads and adverse weather conditions. Moreover, steel flat bars are readily accessible in various sizes and can be conveniently fabricated to meet specific design requirements, which makes them a favored material in the construction industry.

- Q: Are steel flat bars suitable for making brackets or supports for kitchen appliances?

- Yes, steel flat bars are suitable for making brackets or supports for kitchen appliances. Steel is a strong and durable material that can handle the weight and stress of holding up kitchen appliances. Additionally, steel has a high resistance to heat, making it a safe choice for use in the kitchen. The flat shape of the bars allows for easy installation and provides a stable and secure support for the appliances. Overall, steel flat bars are a reliable and practical choice for making brackets or supports for kitchen appliances.

- Q: Where can I buy ground level bending machine?

- When galvanized round steel is connected with galvanized flat steel, its length is not less than 6 times of the diameter of round steel. If necessary, it should be welded at right angle with auxiliary round steel or flat steel.

- Q: Construction of electrical grounding steel flat buried anti-corrosion requirements, galvanized steel flat welding parts should be done anti-corrosion treatment, not welding parts are also doing anti-corrosion treatment?

- The welding part needs to corrosion because in the welding process the heat melted metal surface coating, so this part, other parts such as did not cause damage to the galvanized layer in the construction process, there is no need for antiseptic treatment.

- Q: How do steel flat bars compare to other types of metal flat bars?

- Steel flat bars have several advantages over other types of metal flat bars. Firstly, steel is known for its strength and durability, making it a reliable choice for various applications. Steel flat bars can withstand heavy loads and are less likely to bend or break under pressure compared to other metals. Additionally, steel flat bars offer excellent corrosion resistance, especially when compared to metals like aluminum or copper. This makes them suitable for outdoor or marine environments where exposure to moisture or saltwater is common. Another advantage of steel flat bars is their versatility. They can be easily welded, formed, or machined to meet specific requirements. Steel can also be heat-treated to enhance its properties, such as hardness or toughness. Furthermore, steel flat bars are readily available in a wide range of sizes and thicknesses, making them suitable for various construction, manufacturing, and industrial applications. They are commonly used in structural support, frames, brackets, and machinery components. However, it is important to note that steel flat bars may be heavier than other metals, such as aluminum. This can be a consideration when weight is a concern, especially in industries like aerospace or automotive. Overall, steel flat bars offer a combination of strength, durability, corrosion resistance, and versatility that makes them a popular choice in many industries.

- Q: Can steel flat bars be used for making hand tools or gardening equipment?

- Absolutely, steel flat bars are ideal for crafting hand tools and gardening equipment. Steel, renowned for its strength and durability, is widely employed in the production of diverse tools and equipment. The malleability of steel flat bars enables effortless shaping and customization to cater to the particular requirements of hand tools and gardening equipment. These bars can be utilized for fabricating handles, blades, brackets, or any other necessary component in these applications. Moreover, steel flat bars boast corrosion resistance and can endure rigorous use, rendering them perfect for tools and equipment that are exposed to outdoor elements or demanding gardening tasks.

- Q: Are steel flat bars corrosion resistant?

- Steel flat bars are not inherently corrosion resistant. However, the level of corrosion resistance depends on the type of steel used and any additional treatments or coatings applied to the surface of the bars. Stainless steel flat bars, for example, are highly corrosion resistant due to the presence of chromium, which forms a protective oxide layer on the surface. On the other hand, carbon steel flat bars are more prone to corrosion, especially in environments with high moisture or exposure to corrosive substances. To enhance the corrosion resistance of carbon steel flat bars, they can be galvanized or coated with protective coatings like paint or epoxy. Overall, it is important to consider the specific type of steel and any additional treatments when assessing the corrosion resistance of steel flat bars.

Send your message to us

Flat Steel high quality slitting hot rolled q235 black carbon steel flat bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords