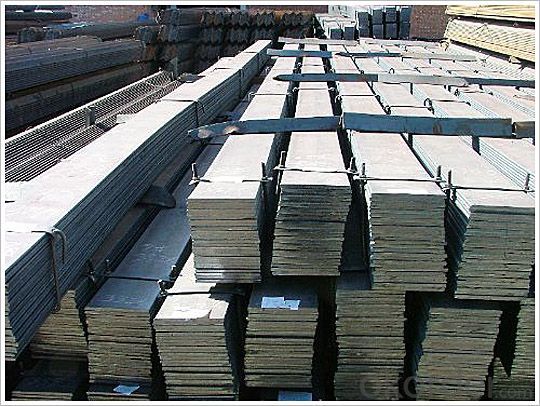

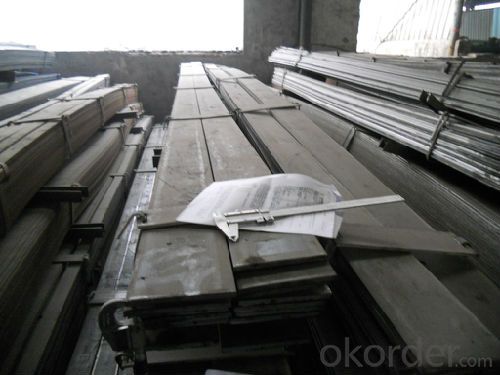

Flat Steel A36 Q235 SS400 Slit Ms Carbon Mild Hot Rolled

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 27 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Flat Steel A36 Q235 SS400 Slit Ms Carbon Mild Hot Rolled at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Flat Steel A36 Q235 SS400 Slit Ms Carbon Mild Hot Rolled are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Flat Steel A36 Q235 SS400 Slit Ms Carbon Mild Hot Rolled are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Flat Steel

1.Thickness:1.5mm-14mm

2.Width:10mm-1010mm

3.Grade:Q235, Q345, A36

3.Factory producing, guaranteed material

| Flat Steel | |||

Width (mm) | Thickness (mm) | Length (m) | Theoretical Weight (kg/m) |

| 20 | 2.0 | 6/9/12 | 0.31 |

| 20 | 2.5 | 6/9/12 | 0.39 |

| 20 | 2.75 | 6/9/12 | 0.43 |

| 25 | 2.5 | 6/9/12 | 0.49 |

| 25 | 3.75 | 6/9/12 | 0.74 |

| 30 | 2.5 | 6/9/12 | 0.59 |

| 30 | 3.5 | 6/9/12 | 0.82 |

| 30 | 9.75 | 6/9/12 | 2.30 |

| 40 | 3.5 | 6/9/12 | 1.10 |

| 40 | 4.75 | 6/9/12 | 1.50 |

| 40 | 11.75 | 6/9/12 | 3.69 |

| 50 | 2.75 | 6/9/12 | 1.08 |

| 50 | 4.5 | 6/9/12 | 1.77 |

| 50 | 9.75 | 6/9/12 | 3.83 |

| 60 | 5.5 | 6/9/12 | 2.60 |

| 60 | 7.5 | 6/9/12 | 3.53 |

| 60 | 11.5 | 6/9/12 | 5.42 |

| 80 | 5.5 | 6/9/12 | 3.45 |

| 80 | 7.5 | 6/9/12 | 4.71 |

| 80 | 11.75 | 6/9/12 | 7.38 |

| 100 | 3.25 | 6/9/12 | 2.55 |

| 100 | 4.75 | 6/9/12 | 3.73 |

| 100 | 7.5 | 6/9/12 | 5.89 |

| 120 | 9.75 | 6/9/12 | 9.18 |

| 120 | 11.75 | 6/9/12 | 11.07 |

| 150 | 9.75 | 6/9/12 | 11.48 |

| 150 | 11.5 | 6/9/12 | 13.54 |

| 150 | 13.5 | 6/9/12 | 15.90 |

| 160 | 11.75 | 6/9/12 | 14.76 |

| 200 | 9.5 | 6/9/12 | 14.92 |

| 250 | 5.75 | 6/9/12 | 11.28 |

| 340 | 7.75 | 6/9/12 | 20.68 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q: Are steel flat bars suitable for making gears or sprockets?

- Yes, steel flat bars are suitable for making gears or sprockets. Steel flat bars are commonly used in gear and sprocket manufacturing due to their durability, strength, and ability to withstand high loads and torque.

- Q: Are steel flat bars available in different surface treatments?

- There are various surface treatments available for steel flat bars, allowing for enhanced appearance, durability, and resistance to corrosion. Some common treatments include galvanizing, powder coating, painting, and anodizing. Galvanizing applies a protective layer of zinc to prevent rust and corrosion. Powder coating involves curing a dry powder with heat to create a durable finish. Painting provides both protection and aesthetic appeal. Anodizing, typically used for aluminum, can also be applied to steel flat bars, creating a layer of oxide that improves corrosion resistance and can be colored. These treatments offer different benefits and expand the applications of steel flat bars.

- Q: What are the different types of surface treatments for steel flat bars?

- There are several types of surface treatments for steel flat bars, including galvanizing, painting, powder coating, and hot-dip coating.

- Q: What is the maximum thickness of a steel flat bar?

- The maximum thickness of a steel flat bar can vary depending on the specific type and grade of steel, but it generally ranges from 1/8 inch to 1 inch.

- Q: Why do some buildings need a steel bar around the top?

- Galvanized round steel refers to the cross section of round solid steel. The specifications are expressed in millimeters of diameter, such as 50, which means a round bar of 50 millimeters in diameter. Round steel is not the same as other steel bars. Round steel is round in shape and has no ribs and no ribs, which makes the bonding strength between round bar and concrete very small.

- Q: How long do steel flat bars typically last?

- Steel flat bars typically last for a very long time due to their durability and resistance to corrosion. The lifespan of steel flat bars largely depends on the conditions they are exposed to and the level of maintenance they receive. In general, when properly maintained and protected from moisture and harsh elements, steel flat bars can last for several decades or even longer. However, if exposed to corrosive environments or neglected in terms of maintenance, their lifespan may be significantly reduced. Additionally, factors such as the quality of the steel, the specific alloy used, and the load or stress the flat bars are subjected to can also influence their longevity. It is important to regularly inspect and maintain steel flat bars to ensure their optimal lifespan and performance.

- Q: How do steel flat bars compare to other materials like wood or plastic?

- Steel flat bars are generally stronger and more durable compared to wood or plastic. They have a higher tensile strength, making them more resistant to bending or breaking under heavy loads. Additionally, steel flat bars are less susceptible to warping, rotting, or damage from moisture, unlike wood. Plastic, on the other hand, may not be as strong as steel and can deteriorate over time due to exposure to UV rays or extreme temperatures. Overall, steel flat bars offer superior strength, longevity, and stability, making them a preferred choice for various structural and construction applications.

- Q: What are the different thicknesses available for steel flat bars?

- The different thicknesses available for steel flat bars can vary, but common options include 1/8 inch, 3/16 inch, 1/4 inch, 3/8 inch, and 1/2 inch.

- Q: What is the difference between carbon steel and stainless steel flat bars?

- The main difference between carbon steel and stainless steel flat bars lies in their composition and properties. Carbon steel flat bars are primarily made of iron and carbon, with a maximum carbon content of 2.1%. This makes them strong and durable, but they are not resistant to corrosion. On the other hand, stainless steel flat bars contain a high percentage of chromium (at least 10.5%) along with iron and other elements. This chromium content forms a protective layer on the surface of the steel, making it highly resistant to corrosion and rust. Due to its corrosion resistance, stainless steel flat bars are commonly used in applications where exposure to moisture or chemicals is a concern, such as in marine environments or the food industry. Carbon steel flat bars, on the other hand, are often used in applications where strength and durability are the primary requirements, such as construction and manufacturing. Another notable difference is the appearance. Carbon steel flat bars have a dull gray finish, while stainless steel flat bars have a shiny, reflective surface. This aesthetic difference can be a factor in certain applications where appearance matters, such as architectural or decorative purposes. In summary, the key differences between carbon steel and stainless steel flat bars are their corrosion resistance, composition, and appearance. Carbon steel is strong and durable but prone to corrosion, while stainless steel is highly resistant to corrosion and offers a shiny finish. The choice between the two depends on the specific requirements of the application at hand.

- Q: Are steel flat bars available in different lengths for packaging purposes?

- Yes, steel flat bars are available in different lengths for packaging purposes. Steel flat bars can be cut to specific lengths to meet the packaging requirements of various industries. This allows for efficient and secure packaging of different products. Whether it is for protecting fragile items or securing heavy machinery, steel flat bars in different lengths can be used to provide the necessary support and stability during transportation and storage.

Send your message to us

Flat Steel A36 Q235 SS400 Slit Ms Carbon Mild Hot Rolled

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 27 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords