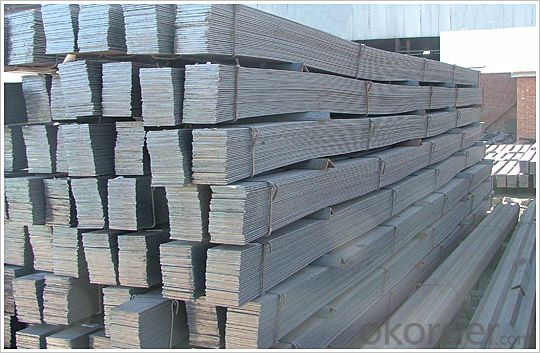

Flat Bar Hot Rolled High Quality 3MM-20MM

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

Flat Bar Hot Rolled High Quality 3MM-20MM are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Flat Bar Hot Rolled High Quality 3MM-20MM are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Commodity: Mild Steel Flat Bar Standard: GB;JIS Material: Q195-235;SS400 Brand name: FLATSPACE Origin place: China Thickness: 3mm-30mm Width:20mm-200mm Length: Max 12m Certification: SGS/BV Chemical composition of Q235

Physical properties of Q235

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q: Are steel flat bars suitable for making industrial equipment?

- Yes, steel flat bars are suitable for making industrial equipment. Steel flat bars have high strength, durability, and resistance to wear and tear, making them ideal for constructing heavy-duty industrial equipment that can withstand harsh conditions and heavy loads. Additionally, steel flat bars can be easily welded, cut, and shaped to meet specific design requirements, allowing for versatility in manufacturing industrial equipment.

- Q: Are steel flat bars suitable for the construction of cultural or arts venues?

- Yes, steel flat bars can be suitable for the construction of cultural or arts venues. Steel flat bars offer strength, durability, and versatility, making them an ideal choice for structural elements such as beams, columns, and supports in these venues. Additionally, the sleek and modern appearance of steel flat bars can complement the aesthetic of cultural or arts venues, enhancing their overall design.

- Q: What are the different standards for steel flat bars?

- Steel flat bars, also known as steel flats or flats, are available in a variety of standards that determine their size, shape, and composition. These standards are established to guarantee consistency and excellence in the production and utilization of steel flat bars. One highly recognized standard for steel flat bars is the ASTM A36, which outlines the prerequisites for carbon structural steel. This standard specifies the chemical composition, mechanical properties, and dimensional tolerances for steel flats used in general structural purposes. Another frequently used standard is the ASTM A108, which covers carbon steel bars for general applications. This standard categorizes steel flat bars into different grades based on their chemical composition and mechanical properties. For more specialized applications, there are specific standards tailored to different industries. For example, the ASTM A276 is a standard that pertains to stainless steel bars and shapes. Within this standard, there are specific requirements for stainless steel flat bars, including their chemical composition, mechanical properties, and dimensions. In addition to ASTM standards, there are also international standards that govern the production and use of steel flat bars. The most notable one is the EN 10058, a European standard that specifies the tolerances on dimensions and shape for hot-rolled steel flat bars. Moreover, there are regional or national standards that may apply in certain countries. For instance, the JIS G3194 is a Japanese industrial standard that provides specifications for hot-rolled steel flat bars used in general structures. These standards are crucial to ensure the quality, compatibility, and interchangeability of steel flat bars in different applications. Manufacturers, engineers, and users rely on these standards to choose and work with steel flat bars that meet their specific requirements and adhere to industry norms.

- Q: How do steel flat bars compare to copper flat bars?

- Steel flat bars are generally stronger and more durable than copper flat bars. Steel has a higher tensile strength and is less prone to bending or warping under heavy loads. Additionally, steel is more resistant to corrosion and can withstand harsh environmental conditions better than copper. However, copper flat bars have superior electrical conductivity and are often preferred for electrical and plumbing applications. Ultimately, the choice between steel and copper flat bars depends on the specific requirements and intended use of the material.

- Q: How do steel flat bars perform in earthquake-resistant designs?

- Steel flat bars can be a key component in earthquake-resistant designs due to their inherent strength and flexibility. These bars are commonly used in structural elements such as beams, columns, and braces, which play a crucial role in absorbing and dissipating the energy generated during an earthquake. One of the main advantages of steel flat bars is their high tensile strength, which allows them to resist the horizontal forces and bending moments imposed by seismic activities. This strength helps prevent structural failure and ensures the integrity of the building during an earthquake. Additionally, steel flat bars have excellent ductility, meaning they can undergo large deformations without fracturing. This characteristic is particularly important in earthquake-resistant designs as it allows the structure to flex and absorb seismic energy, reducing the impact on the building and its occupants. Steel flat bars also possess good weldability, which facilitates their connection to other structural members. This enables engineers to create robust and efficient load paths, ensuring that the seismic forces are evenly distributed throughout the structure, further enhancing its earthquake resistance. Furthermore, steel flat bars are readily available in various sizes and dimensions, making them versatile for different design requirements. Their standardization and ease of fabrication contribute to a cost-effective solution for earthquake-resistant designs. However, it is important to note that the performance of steel flat bars in earthquake-resistant designs also depends on proper engineering and construction practices. The design should consider factors such as the building's location, soil conditions, and anticipated seismic forces to ensure the appropriate selection and placement of steel flat bars. Additionally, proper installation and quality control during construction are crucial to maximize their effectiveness in earthquake resistance.

- Q: Are steel flat bars magnetic?

- Indeed, steel flat bars generally possess magnetic properties. Steel, being primarily composed of iron, is inherently magnetic. Consequently, when iron is combined with various other components to create steel, the resultant substance maintains its magnetic characteristics. Consequently, steel flat bars have an affinity for magnets and can be employed in sectors necessitating magnetic attributes, including industrial machinery, construction, and manufacturing.

- Q: What are the different methods of surface coloring or tinting for steel flat bars?

- There are several methods of surface coloring or tinting for steel flat bars. Some common methods include hot-dip galvanizing, powder coating, electroplating, and chemical patination. Each method offers different advantages and produces unique finishes, allowing for various aesthetic and functional requirements to be met.

- Q: Where can I buy steel flat bars?

- Steel flat bars are available for purchase at different locations. Hardware stores, metal supply companies, and online retailers are among the options. It is advisable to start by checking local hardware stores, as they may have a variety of steel flat bars in various sizes. Metal supply companies usually offer a broader range of choices and can also provide custom cutting services. Furthermore, online retailers like Amazon and specialty metal suppliers offer a convenient means of buying steel flat bars, with the added benefit of a wider selection and competitive prices.

- Q: What is the maximum weight capacity of a steel flat bar?

- The maximum weight capacity of a steel flat bar depends on its dimensions and the grade of steel used. However, in general, steel flat bars can support significant weight loads and are commonly used in construction and industrial applications. It is best to consult the manufacturer or refer to engineering specifications for the specific weight capacity of a particular steel flat bar.

- Q: Can steel flat bars be used for making tools?

- Yes, steel flat bars can be used for making tools. Steel is a strong and durable material that is commonly used in toolmaking due to its high tensile strength and resistance to wear and tear. Flat bars can be easily shaped, cut, and welded to create various types of tools such as wrenches, chisels, and scrapers. The flat surface of the bar provides a stable base for attaching handles or other components, making it suitable for tool construction. Additionally, steel flat bars can be heat-treated to enhance their hardness and toughness, further improving their suitability for toolmaking.

Send your message to us

Flat Bar Hot Rolled High Quality 3MM-20MM

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords