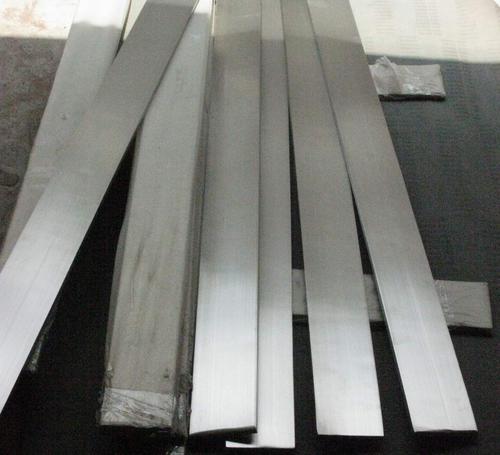

Grade Q235 Flat Bar Low Carbon

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering Grade Q235 Flat Bar Low Carbon at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Grade Q235 Flat Bar Low Carbon are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Grade Q235 Flat Bar Low Carbon are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: slited

Slitting precision (width) : 0.5 mm or less

Raw material: Q235B, Q345B, Q235-1 b

crosscutting precision (length) : 2 mm or less

Processing: the thickness of 2.0-16 mm;

Shear length: 2000 mm above

Wide degree: 15-1250 - mm;

Leveling precision: 1-2 MM square

Packaging: Export packing, nude packing, bundled

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How many tons of steel products could be loaded in containers?

A2: Usually the steel products are delivered by bulk vessel because of the large quantity and the freight. However, there are no bulk vessel enter some seaports so that we have to deliver the cargo by containers. The 6m steel product can be loaded in 20FT container, but the quantity is changed according to the size, usually from 18tons to 25tons.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The normal sizes with the normal grade can be produced within one month. The specific shipping date is dependent upon international and government factors, the delivery to international main port about 45-60days.

Images:

- Q: Can steel flat bars be used for manufacturing hand tools?

- Yes, steel flat bars can be used for manufacturing hand tools. Steel is a commonly used material for hand tools due to its strength, durability, and resistance to wear and tear. Steel flat bars can be shaped, cut, and forged into various hand tool designs such as wrenches, chisels, screwdrivers, and hammers. The flat shape of the bars allows for easy machining and shaping, making it a suitable choice for manufacturing hand tools. Additionally, steel has excellent mechanical properties, making it capable of withstanding high stress and providing a solid grip for users.

- Q: Can steel flat bars be used in the manufacturing of machinery?

- Yes, steel flat bars can be used in the manufacturing of machinery. Steel flat bars are commonly used in the construction of machinery components due to their strength, durability, and versatility. They can be shaped, cut, and welded to create various machine parts such as brackets, supports, frames, and structural elements. Additionally, steel flat bars offer good resistance to impact, wear, and corrosion, making them suitable for industrial applications in the manufacturing sector.

- Q: Are steel flat bars available in different colors or finishes?

- Different colors or finishes are typically not available for steel flat bars. The main purpose of steel is its strength and durability, rather than its aesthetic appeal. Nevertheless, there are cases where steel flat bars can be painted or powder coated in various colors for decorative reasons. Moreover, steel can be treated or coated with different finishes, like galvanized or stainless steel, to enhance its resistance to corrosion.

- Q: What are the different sizes of steel flat bars?

- Steel flat bars come in a variety of sizes to suit different applications and requirements. Common sizes of steel flat bars include 1/8 inch thick by 1/2 inch wide, 1/4 inch thick by 1/2 inch wide, 3/8 inch thick by 1/2 inch wide, and 1/2 inch thick by 1/2 inch wide. However, these are just a few examples, as steel flat bars can be found in a wide range of thicknesses and widths. Some larger sizes may include 1 inch thick by 4 inches wide or even larger. The specific size of a steel flat bar needed will depend on the intended use, load-bearing capacity, and the desired strength of the steel. It is important to consult a steel supplier or reference an industry standard to determine the appropriate size for a specific application.

- Q: Can steel flat bars be cut to specific lengths?

- Yes, steel flat bars can be cut to specific lengths.

- Q: Are steel flat bars suitable for making furniture?

- Yes, steel flat bars are suitable for making furniture. They are strong, durable, and can be shaped into various designs.

- Q: How do steel flat bars contribute to the overall aesthetics of a design?

- Steel flat bars can contribute to the overall aesthetics of a design in several ways. Firstly, their sleek and clean lines can add a modern and contemporary look to any design. The straight edges and sharp corners of steel flat bars create a sense of precision and order, giving the design a polished and sophisticated appearance. Additionally, steel flat bars can be easily manipulated into various shapes and forms, allowing for endless design possibilities. They can be bent, twisted, or welded together to create intricate patterns, unique textures, or even sculptural elements. This versatility enables designers to incorporate steel flat bars into a wide range of projects, from furniture and architectural features to decorative accents and art installations. Furthermore, steel flat bars often have a shiny and reflective surface, which can enhance the visual appeal of a design. The polished finish of steel can catch and reflect light, adding a touch of elegance and brightness to the overall aesthetic. This reflective quality can also create interesting visual effects, such as mirroring or playing with the surrounding environment. Lastly, steel flat bars are known for their strength and durability, which can contribute to the longevity and resilience of a design. The solid and robust nature of steel can convey a sense of stability and reliability, making the design appear solid and well-built. This perception of strength can have a positive influence on the overall aesthetic, as it communicates a sense of quality and craftsmanship. In conclusion, steel flat bars contribute to the overall aesthetics of a design by providing sleek lines, versatile forms, reflective surfaces, and a perception of strength. Their modern look, design flexibility, and durability make them a popular choice for designers who seek to create visually appealing and long-lasting designs.

- Q: Can steel flat bars be used for making brackets or supports for power generation equipment?

- Yes, steel flat bars can be used for making brackets or supports for power generation equipment. Steel is a strong and durable material that can provide the necessary stability and strength required for supporting heavy equipment. Additionally, steel flat bars can be easily shaped, welded, and customized to fit specific design requirements, making them suitable for constructing brackets and supports in power generation applications.

- Q: Can steel flat bars be used for making stairs or handrails?

- Steel flat bars are an excellent choice for the construction of stairs and handrails. Being highly durable and strong, they can withstand heavy usage and offer reliable support. With steel flat bars, it is possible to shape and weld them to achieve the desired design and structure for stairs and handrails. Moreover, steel can be coated or painted with different finishes to enhance its visual appeal and protect it against corrosion. In conclusion, due to their strength, versatility, and durability, steel flat bars are widely favored for the creation of stairs and handrails.

- Q: Are steel flat bars commonly used in the construction of industrial buildings?

- Steel flat bars are frequently utilized in the construction of industrial buildings. Steel is an adaptable and long-lasting substance that is extensively employed in construction because of its robustness and capacity to endure substantial loads. In industrial buildings, flat bars are favored as they provide a steady and uniform surface for supporting structures, framing, and reinforcement. They serve as beams, columns, and braces, offering crucial structural stability to the building. Moreover, steel flat bars are easily manipulated and can be tailored to suit specific design prerequisites, making them the preferred option in industrial construction undertakings.

Send your message to us

Grade Q235 Flat Bar Low Carbon

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords