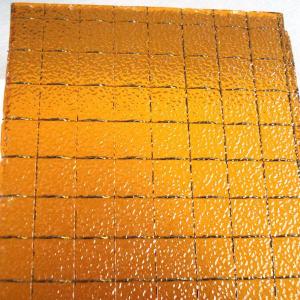

Fire-resistant Wired Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m2 m.t.

- Supply Capability:

- 3000 m2 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Wire glass is a kind of reinforced safe and decorative flat glass with wired mesh embedded in the glass by a special mesh unwinding system during glass forming.

Features of Fire-resistant Wired Glass:

Good optical property: the transmittance is the same as float glass.

High strength: its strength is 6-12 times the strength of common float glass, it belongs to a

kind of safety glass.It can be incorporated into insulating glass with the functions of energy saving, sound

insulation and heat insulation. It can also be used to process coating glass with the effect of

heat reflection and artistic beauty.

Specifications of Fire-resistant Wired Glass:

Thickness: 3-19mm

Size: 3660*2440mm

300*300mm

customized size

Applications of Fire-resistant Wired Glass:

Wired Glass is mainly used in construction such as curtain walls, doors and windows,

partitions, etc.

- Q: Tile selection, paving process

- Clean up the grass ground, cement mortar, fixed elevation, elastic line, sheet materials choosing, soaking wet, standard for the installation of block, paving cement mortar, paving stone, pouring and cleaning, maintenance and commissioning.

- Q: Is the balance pad the raw material in the motor?

- Its main function is the use of mechanical energy into electrical energy, the most common is the use of thermal energy, water power, and so on to promote the generator rotor to generate electricity.

- Q: The benefits of natural thin wood planks

- Sheet material means a flat rectangular building material plate with a width of more than 2 times its thickness, usually made of flat rectangular building material, used as a wall, ceiling, or floor member. Also refers to the forging, rolling or casting of the metal plate, divided into thin plate, medium plate, thick plate, thick plate, usually made of standard size flat rectangular building material board.

- Q: What are the raw materials for low dielectric glass fiber?

- Glass fiber according to shape and length, can be divided into continuous fiber length, fiber and glass wool; according to the glass component, can be divided into non alkali, chemical resistance, high alkali, alkali, high strength, high elastic modulus and alkali resistant glass fiber etc..The main raw material for the production of glass fiber are: quartz sand, limestone, dolomite, alumina and pyrophyllite, boric acid, sodium carbonate, mirabilite and fluorite etc.. The production methods can be roughly divided into two categories: one is the molten glass directly into the fiber; one is the molten glass into the first 20mm diameter glass ball or rod, in a variety of ways made by heating a diameter of 3 ~ 80 m very fine fiber. An infinitely long fiber drawn from a platinum alloy plate by mechanical wire drawing is called continuous glass fiber, commonly known as long fiber. A discontinuous fiber made from a roller or air flow, called a fixed length glass fiber, commonly referred to as staple. Fine, short, flocculent fibers made from centrifugal force or high velocity air flow, called glass wool. Glass fibers are processed into various shapes, such as yarn, roving, chopped strand, cloth, band, felt, plate, tube, etc..

- Q: What are the paper made of? What is the glass made of? What is the plastic made of?

- Basically, paper is made from vegetable fiber.

- Q: What are the raw materials for making glass?

- The main raw material for making glass is sand, its main component is silica, which is commonly called quartz.

- Q: Does anyone know iPhone's toughened glass production process? Thank you

- Glass raw materials, after inspection, began processing, usually in accordance with the equipment conditions of the factory, pre cutting or no pre cutting required;

- Q: FRP process piping manufacturing process?

- A, lined with resin preparation. According to the quality control department according to the work environment, temperature conditions made resin formula system for lining resin matching, batching quantity according to the manufacturing schedule reasonable grasp. When the situation changes, the quality inspection department and the manufacturing department shall adjust the formulation in time, and prepare the resin according to the new formula;B, material preparation. According to the design requirements, the material needed for making the lining is transported to the designated position, and some wide width reinforcement materials are firstly cut and processed to the design width;C, lining production. According to the design requirements of the paving layer step liners, each layer in the process of laying under reasonable tension between the amount of overlap, and combined pressure roller rolling repeatedly from bubble to ensure fiber soaked completely. And requests each enhancement material layer to achieve the design resin content request;D, preliminary self check. According to the design requirements of overlay end of each layer, the operation requirements for quality testing of workers: whether the design meets the lining thickness, whether there is a local poor glue, hanging glue phenomenon, whether there is a white spot, whether there is a bubble, etc., if the occurrence of the above situation timely report and take measures;

- Q: May I ask what specific aspects of German foam glass and foam glass made in China are?

- Capacity: the above shows that capacity can not be compared.Quality: a precision controlled machine control, one is artificial ratio, so the quality of the domestic production line is relatively unstable.Because of 100% waste glass, we can really achieve the characteristics of silica, physical weather resistance can be confirmed.

- Q: What kind of film is toughened glass film?

- Tempered glass (Temperedglass/Reinforcedglass) belongs to safety glass. Glass has a fairly good abrasion resistance and is very hard, with a Vivtorinox hardness of 622 to 701. Toughened glass is a kind of prestressed glass, in order to improve the strength of the glass, the methods commonly used in chemistry or physics, formed on the surface of glass glass under compressive stress, first offset surface stress force, so as to improve the bearing capacity of reinforced glass, its wind, cold, impact etc.. The toughened glass protective film is the highest security level for mobile phone screen protection.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2007 |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | Nov. 30th, 2013 |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | 10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | |

Send your message to us

Fire-resistant Wired Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m2 m.t.

- Supply Capability:

- 3000 m2 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords