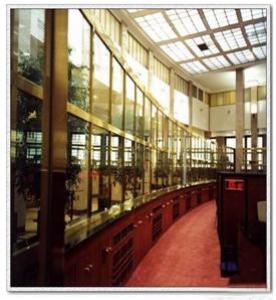

Fire-resistant Glass-4

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fire-resistant Glass is produced adopting new technology. After test analysis, the property of it can be compared with foreign products. What’s more, the processing technology and the product performance take the lead at home in China. It includes wired glass.

Features:

1、Good optical property: the transmittance is the same as float glass.

2、High strength: its strength is 6-12 times the strength of common float glass, it belongs to a kind of safety glass.

3、It can be incorporated into insulating glass with the functions of energy saving, sound insulation and heat insulation. It can also be used to process coating glass with the effect of heat reflection and artistic beauty.

Specifications:

Thickness: 3-19mm

Size:

3660*2440mm

300*300mm

customized size

Applications:

Fire-resistant Glass is mainly used in construction such as curtain walls, doors and windows, partitions, etc.

- Q: The use of quartz sand

- Quartz sand is quartz quartz stone crushing processing, quartz stone is a kind of non metallic minerals, is a hard, wear-resistant, stable chemical properties of silicate minerals, its main mineral composition is SiO2, quartz sand, the color is white or colorless and translucent, Mohs hardness of 7, quartz sand is [1] an important industrial mineral raw material, non hazardous chemicals, widely used in glass, casting, ceramics and refractories, smelting, metallurgy, metallurgy, construction, chemical agent, rubber, plastics, abrasives, and other media industry

- Q: What are the main raw materials for making ceramics, glass and cement?

- The main raw materials for producing ceramics are clay (such as Suzhou soil), quartz, feldspar (potassium feldspar and albite)

- Q: How is glass made? What are the main ingredients?

- Preparation of batch. According to the product, the composition of the mixture is slightly different. For example, ordinary float glass batch (calculated in accordance with 1 weight boxes of 50 kilograms), need to consume 33.55 kg of quartz sand, limestone, dolomite, 2.96 kg 8.57 kg 11.39 kg of soda, Glauber's salt 0.55 kg, 3.45 kg, 0.03 kg of feldspar powder etc..

- Q: What is glass made of?

- According to the designed material sheet, the raw materials are weighed and mixed evenly in a mixer. The main raw materials of glass are: quartz sand, limestone, feldspar, soda ash, boric acid and so on.

- Q: Is the balance pad the raw material in the motor?

- An electric machine is an electromagnetic device that converts or transfers electrical energy according to the law of electromagnetic induction. In a circuit, use the letter M (the old standard uses D). Its main function is to generate driving torque, as a power source for electrical appliances or various machines. The generator is represented by the letter G in the circuit.

- Q: The benefits of natural thin wood planks

- Sheet metal products, flat appearance, thickness ratio, surface area per unit volume is large, the shape features bring its use characteristics: (1) a large surface area, so the inclusive coverage ability, have been widely used in chemical industry, container, construction, metal products, metal structure; (2) can be arbitrary cutting, bending, stamping, welding, made of a variety of products, flexible and convenient use, occupies an extremely important position in the Department of automobile, aviation, shipbuilding and tractor manufacturing; (3) bending, welding into all kinds of complicated section steel, steel tube, steel I-beam, large pieces of the structure, it is known as the "universal steel".

- Q: What kind of mineral is glass made of?

- Colored glass is made by adding some metal oxides in the manufacture of ordinary glass. Cu2O - red; CuO - blue-green; CdO - pale yellow; CO2O3 - blue; Ni2O3 - dark green; MnO2 - purple; colloidal Au - red; colloidal Ag - yellow)

- Q: What happens when toughened glass breaks?

- This is because of containing nickel sulfide crystal glass raw material, manufacturing technology in the world is any existing can not be completely avoided, only reduce the exploding probability through control of the purity of raw materials and processing technology to a.

- Q: How do I see whether the raw material of tempered glass is made of float glass or standard glass?!

- Float glass: float glass surface flat, good brightness, no bubble and tumorLattice glass: the surface of the lattice is not very smooth, and the ripples can be seen from the side. Uneven thickness

- Q: Mobile phone film new flexible toughened glass membrane, really is the glass?

- Toughened glass is a kind of prestressed glass, in order to improve the strength of the glass, the methods commonly used in chemistry or physics, formed on the surface of glass glass under compressive stress, first offset surface stress force, so as to improve the bearing capacity of reinforced glass, its wind, cold, impact etc.. The toughened glass protective film is the highest security level for mobile phone screen protection.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2008 |

| Annual Output Value | US$ 1 Million - US$ 2.5 Million |

| Main Markets | Northern Europe, Africa |

| Company Certifications | Certificate for China Compulsory Product Certification |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 21% - 30% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 9 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered; Buyer Label Offered |

| Product Price Range | Average |

Send your message to us

Fire-resistant Glass-4

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords