Fire-rated Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100m2 m²

- Supply Capability:

- 10000m2 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

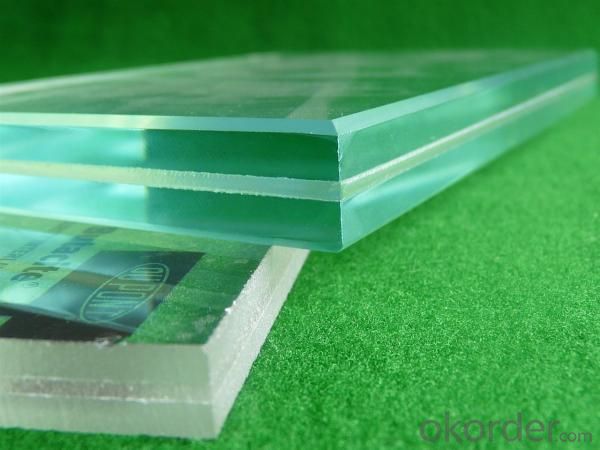

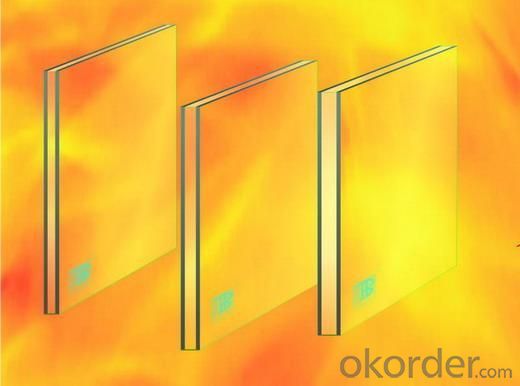

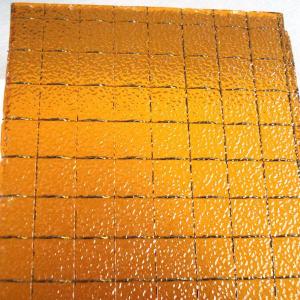

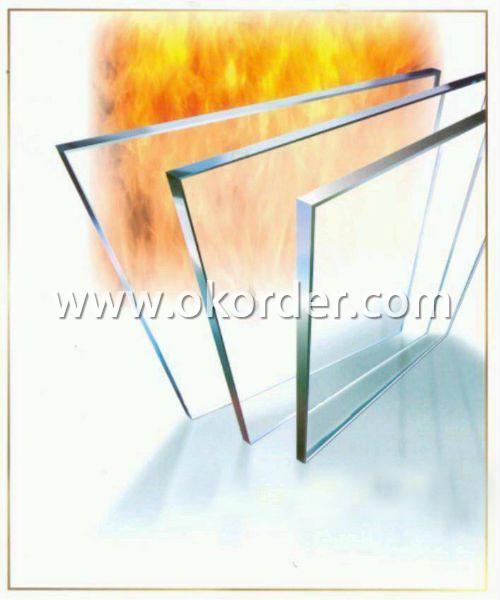

Fire-rated Glass is produced adopting new technology. After test analysis, the property of it can be compared with foreign products. What’s more, the processing technology and the product performance take the lead at home in China. It includes wired glass.

Features of Fire-rated Glass:

1、Good optical property: the transmittance is the same as float glass.

2、High strength: its strength is 6-12 times the strength of common float glass, it belongs to a kind of safety glass.

3、It can be incorporated into insulating glass with the functions of energy saving, sound insulation and heat insulation. It can also be used to process coating glass with the effect of heat reflection and artistic beauty.

Specifications of Fire-rated Glass:

Thickness: 3-19mm

Size:

3660*2440mm

300*300mm

customized size

Applications of Fire-rated Glass:

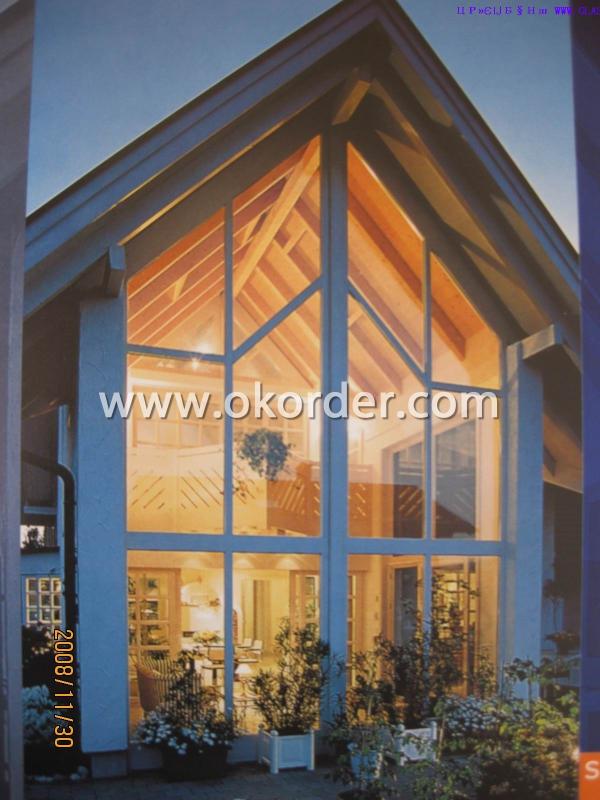

Fire-resistant Glass is mainly used in construction such as curtain walls, doors and windows, partitions, etc.

- Q: What is the raw material of glass products?

- Ordinary glass raw materials are soda ash (sodium carbonate), limestone (calcium carbonate) and silica, after a high temperature reaction, the products are mainly sodium silicate, calcium silicate and silica

- Q: How can glass frosting be formulated? What raw materials do you use?

- 1. Prepare glass cleaning solution:Pour 6 parts of tap water and 1 parts of hydrofluoric acid into plastic container. Stir well.2. Glass cleaning:The glass will be placed on the cleaning shelf, then use the sponge coke on the glass solution, wipe evenly on the surface of the glass, the glass surface cleaning liquid to stay in 5-10 seconds, and then rinse with water glass, (to ensure the glass surface without stains, so as not to affect the frosting effect.)Please note: in the glass side 3-5 seconds before frosting, the water drained, they bring too much water in the frosting liquid, effect of frosting liquid.

- Q: How is glass made? I heard that sand is used, but what is the concrete principle?

- Technological process:1, raw materials broken: the above raw materials broken into powder;2, weighing: according to the list of ingredients, called a certain amount of powder;3, will be called: the mixed powder mixing, stirring into a batch (colored glass and colorant);4, melting: the mixture into the glass furnace, melting at 1700 degrees into glass;5, forming: the glass liquid into a tin bath (float), pull machine (lattice method), rolling machine (rolling method, adding metal wire is wire glass), forming the flat glass;6, annealing: the molding of glass products into the annealing furnace annealing, balance the stress, to prevent self cracking.

- Q: The main raw material for the impact of float glass cost?

- Process: mainly to see whether the enterprise has mastered the key technology of float process control. For example, master the melting technology, need to have stripe analysis equipment to monitor, can detect fault signs in advance, timely fine-tuning, can avoid major accidents, development. In the case of melting stability, general forming and annealing are relatively easy to achieve stability; the products produced by such a line are stable and the cost will be greatly reduced. But at present, the only part of enterprises to master the technology, many enterprises are repeatedly in fluctuation, a fluctuation of about 3-7 days, so the product quality can not guarantee long-term stability, there is no guarantee to do the processing of glass, benefits decline.

- Q: What kind of material is the glass made of? Is the price relative to the quality?

- The main constituents of the glass are calcium silicate, sodium silicate and silicaExpensive and not expensive must be related to quality (at least with impurities)

- Q: Does fiberglass contain formaldehyde? I'm a hair salon. Buy a glass fiber reinforced plastic shampoo bed, there is always a pungent smell of the body, there is no harm to it, including formaldehyde free

- The pungent smell is not necessarily formaldehyde, and FRP is also called GRP, that is, fiber reinforced plastics, generally refers to glass fiber reinforced unsaturated polyester, epoxy resin and phenolic resin matrix.

- Q: The shell of glass steel electric cars will not be on the poor out of the glass Sizha?

- Such as glass fiber reinforced plastic products used for a long time will cause bare glass fiber, this situation is only a very low-end manufacturers will appear, because they use the resin does not know where it came from. Really sophisticated material manufacturers out of the glass steel shell, even if your car is worn out, will not appear bare glass phenomenon, unless you use a weapon to draw it. I worry about the effects of glass fiber dust on the body, that you do not have to worry about, FRP is inferior can lead to itching, and the glass tube can do high-quality drinking water, the quality of glass steel products has been cured is harmless to the human body.

- Q: How is glass made? What material is it made of?.

- Bullet proof glass is made of glued laminated material, which is glued together with many pieces of glass or high strength organic board. Generally has the following three layers of structure:Bearing layer: firstly, the layer is broken by impact, and the glass with large thickness and high strength is used. It can destroy warhead or change warhead shape, and make it lose the ability to move forward.Transition layer: the general use of organic adhesive material, strong adhesion, light fastness, can absorb part of impact energy, change the direction of the bullet forward. A very strong and transparent chemical film is sandwiched between laminated glass. This can not only effectively prevent bullet shooting, but also has the properties of surge resistance, explosion resistance, shock resistance and no cracks after impact.Safety protection layer: this layer is made of high strength glass or high strength transparent organic material. It has better elasticity and toughness, can absorb most impact energy, and ensure that the bullet can not penetrate the layer

- Q: There are several ways of heating the industrial drying tunnel furnace and are different from each other?

- The utility model has the advantages of long service life and high reliability. The heater is made of special electric heating material, and the design power load is reasonable, and the heater adopts multiple protection, so that the safety and the service life of the heater are greatly increased.

- Q: What's the connection between tempered glass and float glass?

- Tempered glass is made of ordinary glass in the tempering furnace

1. Manufacturer Overview

| Location | Guangdong, China |

| Year Established | 1994 |

| Annual Output Value | |

| Main Markets | Japan; Singapore; Southeast Asia |

| Company Certifications | ISO9001;ISO14001;OHSAS18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shantou; Shenzhen |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 54000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Fire-rated Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100m2 m²

- Supply Capability:

- 10000m2 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords