Insulated Glass and Curtain Wall Insulated Glass 5+9A+5mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Square Centimeter/Square Centimeters m²

- Supply Capability:

- 10000 Square Centimeter/Square Centimeters per Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

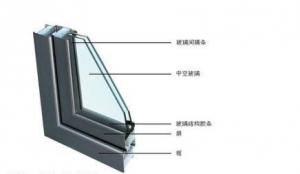

Introduction of Insulated Glass & Curtain Wall Insulated Glass 5+9A+5mm

Function: Insulated Glass Shape: Curve,Flat Structure: Hollow Technique: Clear Glass,Coated Glass,Tempered Glass

Type: Float Glass

Packaging & Delivery of Insulated Glass & Curtain Wall Insulated Glass 5+9A+5mm

Packaging Details: Wooden crates worthy for ocean and land carriage

Delivery Detail: 30% T/T in advance, and balance before shipment

Specifications of Insulated Glass & Curtain Wall Insulated Glass 5+9A+5mm

soundproof wall glass

5+9A+5mm Insulated Glass & Curtain Wall Insulated Glass

Minimum Order Quantity: 25 Ton/Tons 1 FCL

Port: Qingdao Port, China

Packaging Details: Wooden crates worthy for ocean and land carriage.

Size: 800*900mm, 1200*1500mm etc.

Thickness: 5+9A+5mm, 6+12A+6mm etc

MOQ:1 FCL

Packing : Wooden crates worthy for ocean and land carriage

- Q: Chemical materials and additives needed for the production of glass

- 1. Blending of raw materials. The main ingredients of float glass are: 73% of silica, 13% of sodium carbonate, 9% of calcium oxide and 4% of magnesium. The ingredients are mixed in proportion, followed by the addition of small pieces of recycled glass.2. Melting of raw materials. The prepared material passes through a mixing bin and then goes into a kiln with 5 chambers and is heated at about 1550 degrees centigrade to become a molten glass. 3. Glass forming. Molten glass flows into a tin bath and floats over molten molten tin, at a temperature of about 1000 degrees celsius. The molten glass on the tin solution forms a glass band of 3.66 meters wide and a thickness of 3mm to 19mm. Because the glass and the tin are very different in viscosity, the molten glass at the top does not mix with the molten tin below, and forms very smooth contact surfaces.4. Cooling of molten glass. When the glass band leaves the bath, the temperature is about 600 degrees Celsius, then it enters the annealing chamber or the continuous cooling kiln, and the temperature of the glass is gradually reduced to 50 degrees celsius. Thus, the glass produced by the Xu cooling method is also called annealed glass. 5, cutting and storage. After the cold, the glass passes through several stages of quality inspection, then cut into different sizes for packaging, storage, storage or transportation.Quartz sand is a hard, abrasion resistant and stable chemical silicate mineral. Its main mineral composition is SiO2, the color of quartz sandFor the white, colorless or translucent, 7 hardness, brittle cleavage, conchatus fracture, oil sheen, density 2.65, bulk density (1-2.0 = 1.6), 20-200 was 1.5, the chemical, thermal and mechanical properties have obvious anisotropy, insoluble in acid, slightly soluble in KOH solution, the melting point of 1750 DEG C.

- Q: I want to ask, if the home is already hollow glass, that still need to foil it?

- The insulating glass production enterprises are numerous, and the enterprise scale is relatively small. The quality of products is unstable. Products are good and bad, the phenomenon is more serious, even worse, inferior insulating glass is still flooding the market.

- Q: What is the raw material for making glass?

- The 60% component of the crystal is "two oxide" (SiO2). The color of the crystal is due to the addition of two silicon oxide, which also contains a variety of trace metals. In the natural environment, and most of crystal mineral calcite, pyrite, iron ore, Hui various colors of mica, Biqian, granite, Jin Hongshi and other "symbiosis", and formed some suspected imaginary scene, the so-called "different" like crystal, crystal increased collection of fun and value.

- Q: What are the raw materials of glass fiber reinforced plastic?

- If they are bonded together with synthetic resins, they can be made of rigid products of a fixed shape, bearing both tensile and flexural, compressive, and shear stresses.

- Q: What is the ratio of raw materials for glass mildew proof powder?

- Coconut shell plant essence ("compendium") from endocarp for palm plants in coconut. Coconut palm in plant form. The chemical composition of coconut shell containing 0.61% ash, 36.51% lignin, cellulose 53.06%, pentosan (29.27% total). Cellulose containing 20.54% pentosan, principal components in the ash and koh.

- Q: What are the raw materials for producing edible glass bottles (such as pickles bottles, fermented beancurd bottles, etc.), and glass is the kind of glass material?

- The production of glass bottles industry, its raw materials are stone powder, quartz sand, soda ash, waste glass and coalA variety of materials used in the preparation of glass batch, collectively referred to as glass raw materials. In general by the 7-12 component, the main material is 4-6, such as quartz sand, limestone, feldspar, sodium carbonate, boric acid, lead compounds, barium compounds, according to the introduction of oxides in the glass structure effect, can be divided into glass forming oxide materials, intermediate oxide materials, network oxides materials, according to the the properties of oxide, can be divided into raw material, acid alkali metal oxide oxide materials. The glass batch is obtained some necessary properties and accelerate the melting process of raw materials, although less, but it is very important that these materials as clarifying agent, fluxing agent, coloring agent, bleaching agent, emulsifying agent, oxidizing agent and reducing agent etc..The same raw materials, different formulations, the same raw materials, different habitats and different indicators, will affect product quality and production costs. In the case of a small gap in raw material costs, the glass bottles produced are very different from each other in the comparison of small samples, and the difference can only be seen in batch production.

- Q: Tempered and reinforced glass

- National construction technical specification for application of glass JGJ113-2003 provisions of the landing door glass must use safe glass, is from the protection of person to consider.

- Q: Is the raw material of organic glass harmful to human body?

- The chemical name of this polymer transparent material is called poly (methyl methacrylate) (PMMA), which is polymerized from methyl methacrylate.

- Q: How is glass made? What material is it made of?.

- Bulletproof glass is made of glass (or organic glass) of a composite material and the quality of engineering plastics through special processing is obtained, it is usually transparent material, usually including polycarbonate layer on glass layer.

- Q: Samsung LCD panel information

- The power supply needs to look at the output power, the output voltage, such as the 26 inch and 32 inch power supply on the market. Other sizes of LCD, or need to consult manufacturers of power supply, specific parameters

1. Manufacturer Overview

| Location | Shandong,China (Mainland) |

| Year Established | 2006 |

| Annual Output Value | |

| Main Markets | 30.00% Africa 20.00% Southeast Asia 10.00% Eastern Asia 10.00% Mid East 10.00% Oceania 10.00% Eastern Europe 10.00% North America |

| Company Certifications | Chinese country compulsory product authentication certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | qingdao |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered Design Service Offered |

| Product Price Range | |

Send your message to us

Insulated Glass and Curtain Wall Insulated Glass 5+9A+5mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Square Centimeter/Square Centimeters m²

- Supply Capability:

- 10000 Square Centimeter/Square Centimeters per Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords