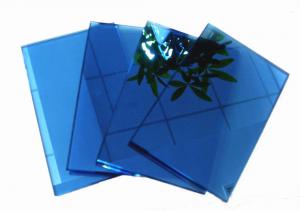

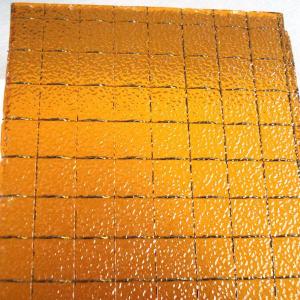

Heat-Reflective Coating Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

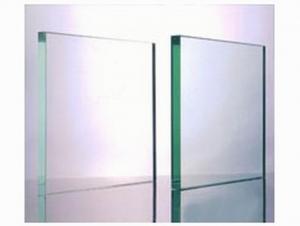

Heat-Reflective Coating Glass, also called Solar Control Coating Glass, is a kind of coated glass which has a specific coating deposited by online CVD (Chemical Vapor Deposition) or offline PVD (Physical Vapor Deposition), making the optical performances of the glass change and producing the required reflective color.

Features:

1. Effectively limit the incident amount/incidence of the solar radiation with obvious shading effect.

2. Have a good view-obscured function for indoor objects and building components.

3. Save energy and reduce the running expenses of air conditioners.

4. Have a good decorative effect for the external walls of buildings.

5. Have a fine view-shielding function for indoor objects and construction components.

6. Designed for single use or composite use into coated laminated glass, coated tempered glass, coated insulating glass or other coated composite glass.

Specifications:

Thickness: 3mm;4mm;5mm;6mm;8mm;10mm;12mm;15mm;19mm

Size:

2440*3660mm

2400*3300mm

2100*3300mm

customized size

Applications:

Heat-Reflective Coating Glass is mainly used for curtain walls.

- Q: What chemicals can be made from glass, paper, detergents, etc?

- Glass: quartz, sodium carbonate, calcium carbonate paper: bark is enough.. cellulose + bleaching agent, such as activated carbon and other detergents, soap bar, sodium stearate

- Q: Civil construction projects, exterior wall glass curtain wall raw materials, or construction process, or the end of the construction, what tests should be done?

- Because I work in the glass curtain wall project, only know raw materials to do a glass curtain wall material impact strength test before installing the unit model, in a special laboratory, no experimental requirements should be in the process of construction, the construction of the end of may do some water resistance experiment. Hope to be of help to you!

- Q: Do solar panels use toughened glass, or are some high light transmitting materials good?

- There are ultra white solar glass. Dedicated to this solar energy

- Q: How is glass made?

- The main raw materials of flat glass are: silica sand (sandstone), sodium carbonate, feldspar, dolomite, limestone and mirabilite.

- Q: What is resin glass fiber reinforced plastic?

- Resin is the main raw material of glass fiber reinforced plastics. The so-called FRP is a kind of composite material made of glass fiber reinforced fiber and its products (glass cloth and band) as reinforcing material and chorus resin as matrix

- Q: What kind of material is the toughened glass film made of mobile phone?

- Tempered glass membrane should be made of tempered glass = =, but this film is not so magical propaganda

- Q: Could you tell me that three yuan ethylene propylene (EPDM) rubber can resist ethylene glycol?

- Three yuan ethylene propylene is ethylene, propylene and non conjugated diene three copolymer. Diene has a special structure, only one of the two keys to copolymerization, unsaturated double bond, mainly as the chain. Another unsaturated polymer will not become the main chain and will only become side chains. The main polymer chain of three yuan ethylene propylene is completely saturated. This property allows three yuan ethylene propylene to resist heat, light, oxygen, especially ozone. Three yuan propylene is essentially non-polar, resistant to polar solutions and chemicals, low water absorption, and good insulation properties.

- Q: Is glass fiber reinforced metal material?

- Glass steel (English: Glass Reinforced Plastic, GRP, or Fiber Reinforced Plastic, English: FRP) also known as glass steel or glass fiber reinforced plastic, is a kind of polymer with epoxy resin as matrix, glass steel or carbon fiber reinforced composite material by composite technology and made.

- Q: How do I see whether the raw material of tempered glass is made of float glass or standard glass?!

- In the sun or under the light, look at the projection, float shadow is very weak, light transmission of good, lattice black lines, one by one

- Q: Failure reasons and solutions of insulating glass.

- To keep the sealant unchanged for a long time, it must require the sealant has good anti-aging properties, if the material quality is not good, it will affect the life of hollow glass products, in all sealants, most can reflect is butyl rubber as the basic raw materials of various types of sealant sealant and moisture barrier properties, and so on standard hollow glass curtain wall curtain wall must adopt double sealing is a very correct decision. Here are a variety of sealants water vapor permeability coefficient table, from the table we can see that the structure of glue can not be used as insulating glass sealant alone.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 1994 |

| Annual Output Value | Above US$ 50 Million |

| Main Markets | Asia; Oceania; Mid East; Eastern Europe; North America; South America; Africa; |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 61% - 80% |

| No.of Employees in Trade Department | Above 1000 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Heat-Reflective Coating Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords