Insulating Glass Made In China

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

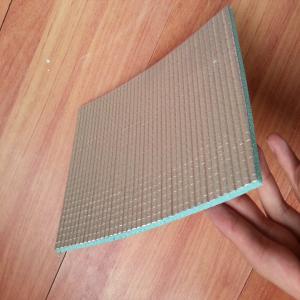

Insulating Glass is made up of two or more pieces of glass which are separated by metal frames, its edge is sealed with the glue by way of jointing and welding.

Features:

1. Heat preservation and energy conservation

2. Anti-frost and anti-dewing

3. Sound insulation

4. The aluminum bar is bent automatically. Automatic molecular-sieve filling system, vertical coupling and vertical automatic sealing can guarantee the production of high-quality insulating glass technically.

5. Compared with common insulating glass, the sealing is reliable for homogenous coating with no bulbs between the layers.

6. good appearance, good dew point

Specifications:

Thickness: 2-19mm

Size:

2500*5000mm(Max)

250*300mm(Min)

Applications:

Insulating Glass is mainly used as building glass in curtain wall, glass doors and windows, etc.

- Q: Which glass factory has good glass?

- Fireproof glass, bullet proof glass, gold mirror, Chajing, black mirror, mirror gray, blue mirror... Is the original piece of glass processing, if the original piece of glass (raw material) of the old good to see the unit of processing technology.

- Q: I want to ask, if the home is already hollow glass, that still need to foil it?

- In the selection of insulating glass raw materials, enterprises one-sided pursuit of profit maximization, resulting in unstable quality of raw materials. Such as sealant is one of the main raw materials of insulating glass, it directly affects the energy-saving effect and service life of insulating glass, but the low price inferior sealant material is still in mass production.

- Q: What are the raw materials for low dielectric glass fiber?

- Glass fiber is divided into different grades according to its composition, properties and uses. According to the provisions of the standard level (see table), E glass fiber is most widely used, widely used in electrical insulating materials; special fiber grade S, while the output is small, but very important, because it has super strength, mainly used for military defense, such as bullet proof box; C level more than E with chemical resistance in the battery isolation plate, chemical filter; a basic glass fiber reinforced materials used in the production.The main component of glass fibre and its main components are silica, alumina, calcium oxide, boron oxide, sodium oxide, Magnesium Oxide, depending on the amount of alkali content in glass, can be divided into non alkali glass fiber (Na2O 0% ~ 2%, which belongs to the aluminum borosilicate glass), glass fiber (8% ~ sodium sodium calcium silicate glass 12%, a boron containing or not containing boron) and high alkali glass fiber (Na2O 13%, sodium calcium silicate glass).

- Q: What's the price of 0.85mm thick plexiglass, please?

- Joint venture material is better, about 600 or so, I personally think that the choice of joint venture board is still ideal.

- Q: How is glass made? What is its raw material?

- Glass is formed by the melting of sand with other chemicals. Glass raw materials for natural ore, the ore will be crushed first, processed into powder, according to the type of glass, according to the formula made of ingredients, into the glass furnace for melting, forming glass liquid. The glass passes through the feed tank and flows out of the feed port to form the stock. The temperature of the stock is 1150~1170 degrees centigrade and the alkali free glass is 1200~1220 degrees centigrade. The material shares every minute near '200 times cut into ball billet. The billet passes through the chute, the ball distributor and the ball plate, and then rolls into different funnels respectively, then falls into a groove formed by three rollers with the same rotating direction. When the ball is rotated on the roller and its surface tension, the ball glass is formed gradually. Its diameter is determined by the thickness, velocity, and shear velocity of the glass stream.

- Q: What kind of material is the glass made of? Is the price relative to the quality?

- The main raw material of silicon dioxide, the price is related to the quality

- Q: What material does PCB have?

- There are many kinds of copper clad laminates. According to different material can be divided into paper substrate, glass cloth substrate and synthetic fiber board; according to the different binder resin is divided into phenolic, epoxy, polyester and polytetrafluoroethylene; use can be divided into general and special type.

- Q: What kind of material is the toughened glass film made of mobile phone?

- General crystalline silicon photovoltaic components using glass and backplane package structure, but there are amorphous silicon photovoltaic components using double glass package. So the glass itself is a piece, commonly known as ultra low iron tempered white suede (suede also wove, back also double glass structure with flat glass)

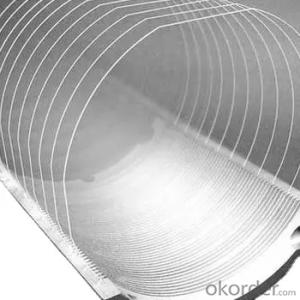

- Q: Which is the best solar water heater tube?

- The surface of the vacuum heat collecting tube is smooth and clean, the pipe body has no spots, no air lines, no scratches and no film forming. (this phenomenon will affect the collection efficiency and beauty).

- Q: Will toughened glass break naturally?

- It blew the concept of rate, the national standard of our country only glass project on the wall, I do not know whether the other foreign industry to use the toughened glass also has detailed provisions.

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 1999 |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | ISO9001;ISO14001;OHSMS18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai, China |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Insulating Glass Made In China

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches