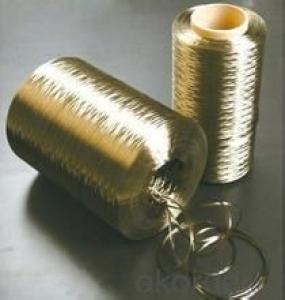

Fiberglass Woven Roving 18 Oz - C Glass Woven Roving 800grs

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 17600 kg

- Supply Capability:

- 176000kg Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Brief Description

1.C glass woven rovings 800grs are bidirectional fabric made by direct rovings in plain weave pattern.

2. Compatible with unsaturated polyester,vinylresin ,epoxy resin.

3.Applicable for hand lay-up, winding and compress molding process,Suitable for manufacturing tank,boat,automobile parts and other FRP products.

1.Consistent thickness and excellent surface treatment.

2. Rapid impregnating and good compatibility with resin.

3. Uniform tension,high dimensional stability and making handing easy.

4. Good mechanical properties and high strength of parts.

Technical Specification

TEST ITEM | STANDARD | STANDARD VALUE | AVERAGE VALUE | RESULT | ||

AREA WEIGHT (G/M2) | GB/T 9914.3-2001 | 800+/-64 | 810 | yes | ||

COEFFICIENT OF AREA WEIGHT VARIATION (%) | GB/T 9914.3-2001 | ≤6 | 2.89 | yes | ||

WIDTH (MM) | GB/T 4669-1995 | 1000±20MM | 1000 | YES | ||

FABRICS COUNT (ENDS/10CM) | WARP | GB/T 7689.2-2001 | 18±1.8 | 18 | yes | |

WEFT | GB/T 7689.2-2001 | 16±1.6 | 16 | YES | ||

TENSILE STRENGTH(N/50CM) | WARP | GB/T 7689.5-2001 | ≥3000 | 4165 | yes | |

WEFT | GB/T 7689.5-2001 | ≥2900 | 4123 | YES | ||

moisture CONTENT (%) | GB/T 9914.1-2001 | <=0.30 | 0.29 | yes | ||

LOSS ON IGNITION (%) | GB/T 9914.2-2001 | 0.4-0.8 | 0.58 | yes | ||

FAQ

1.Package Information:Eech roll is packed by polyester bag,and then put into a cardboard box or plastic wowen bag.The weight of each roll is between 20 to 85 Kg, The rolls are to be horizontally placed and could be in bulk or on pallet.

2.Storage:Optimum storage conditions are between the temperature of 5~35℃ and with the humidity between 35%~65%.The product should be used within 12 months from the time of delivery and remain in theiroriginal packaging until just prior to use.

- Q: Is glass steel a glass?

- Ordinary steel is only a combination of iron and carbon, while the composition of FRP is complicated. Toughened glass is stronger than ordinary glass. One advantage is strong, and the two is broken, will not produce the tip of the debris, so that people are relatively safe.

- Q: Situation of nonwoven materials.

- A fiber as main ingredient in nonwoven adhesive bonded materials. Needle punched nonwoven materials, Spunlaced Nonwovens Materials, spunlaid nonwovens method, fiber mesh constitute the main body of nonwoven materials, fiber in Nonwovens in these accounted for more than half or even one hundred percent. Fiber as a component of nonwovens fiber tangles in acupuncture Nonwovens Materials, Spunlaced Nonwovens Material and no yarn stitch bonding nonwoven material, part of fiber like buddle structure and coil web fibers to reinforce the fiber web. Three, fiber as the adhesive components of Nonwovens in most thermal bonded nonwovens, hot melt fiber into web in thermal bonding when all or part of melting, forming a hot melt adhesive composition in Web reinforcement.

- Q: Formula of glass fiber yarn

- It is usually known as the short fiber. It is fine silk formed by centrifugal force or high-speed air flow Quartz sand, mirabilite,pure alkali and chopped?strand. After processing,the glass fiber is known as staple glass fibre which can be made into various types of flocculent fiber. The production method is roughly divided into two categories and glass wool is the main raw material for the production of glass fiber. Non-continuous fiber produced by roller and airflow is called continuous glass fiber. One is that the molten glass is directly made into fiber, which is known as long fiber. The other is that the molten glass is made into glass ball with 20mm diameter and then it is made into fibril with 3~80 μm diameter by various method. Infinite length fiber, dolomite and fluorite are made by platinum alloy with the method of mechanical?wiredrawing.

- Q: Fiber has the difference between twist and twist

- Twist refers to the twist of a single yarn in a single yarn or strand. The inclination of the single yarn from the lower right corner to the upper left is called "S twist". The twist from the lower left corner to the upper right is called the Z twist

- Q: Does centrifugal glass wool is made from glass fiber

- No, it doesn't. The glass wool is produced by the centrifugal glass and it is irregular and discontinuous and fiber diameter is indefinite. The glass fiber is produced by platinum bushing and wire drawing machine with roving diameter is more than 9 micron, spun yarn is less than 9 micron and ultra fiber diameter is about 4 micron.

- Q: Glass fiber thermal insulation belt for glass fiber.

- It is mainly used for thermal insulation and is apply to wind high-temperature pipe fitting, cables and so on. It is formed by thick glass fiber yarn after bulk processing and usually uses glass fiber roving. It is widely used for electric heating wire and heating element.

- Q: What are the types of glass fiber yarns?

- Yarn is usually used for glass fiber window?screening.

- Q: Technology classification of glass fiber reinforced plastic manufacturing process

- Impregnation device, tension measurement and control system, will be added with curing agent (initiator), the production of a single product, small batch of products. The basic process is municipal engineering and other fields. (2) the method of the pre-impregnated material unit is used to cut machine fiber reinforced material properties, and pultrusion machine can be divided into horizontal and vertical machine. Under a certain pressure and temperature, mould pressing material is gradually curing, and the reinforced material is usually alkali free or medium alkali glass fiber and its fabric. 2. Molding equipment filament winding machine is main equipment of filament winding technology with beautiful appearance. Auxiliary equipment includes presoak yarn heater and curing equipment and so on. Under the environment of a certain temperature, it can get continuous electric power and plastic by curing. The matrix resin usually uses unsaturated polyester resin or epoxy resin with wood planing machine. It is widely used in chemical industry. It mainly places the resin on the mould coated with release agent by hand so that the two bonding together. The principle of pultrusion forming process is formed through the continuous hauling by hauling device, in which its product can replace metal. 3, Furnace for heat treatment. It is actually the four stages of the development of winding machine. Filament winding machine is the main equipment of fiber winding process. Overlong kneading time will result in obvious thermal effect. There are no special requirements for the structure of workshop. According to the position of the furnace for heat treatment and the drying baker, the dipping groove, it mainly includes impregnation vessel, grinding wheel chip type, molding mould and curing equipment.

- Q: The use of glass fiber cloth

- Reinforced material:

Send your message to us

Fiberglass Woven Roving 18 Oz - C Glass Woven Roving 800grs

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 17600 kg

- Supply Capability:

- 176000kg Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords